Method for preparing chitosan and gelatin composite membrane based on anthocyanidin

A technology of anthocyanin and chitosan, which is applied in the field of food intelligent packaging materials, can solve the problems of no freshness indicator, etc., and achieve the effects of wide application range, improved mechanical properties, and enhanced intermolecular forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

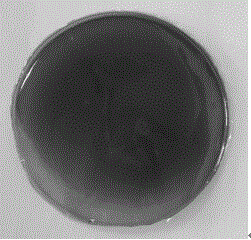

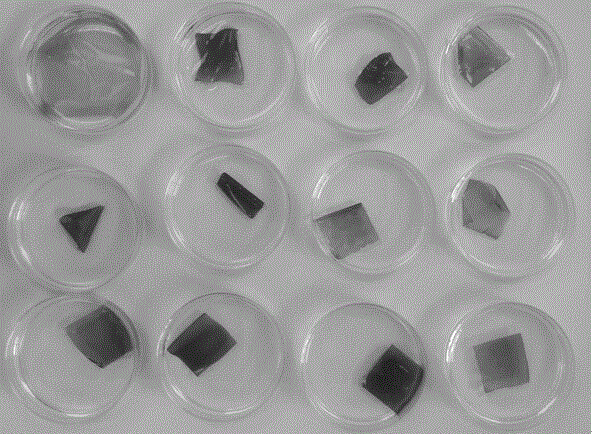

[0041] Example 1: Preparation of composite film with black rice as raw material for anthocyanin extraction:

[0042] (1) Wash and dry the black rice, grind it into a powder with a Chinese herbal medicine grinder; weigh 25g of black rice flour and add 200mL of extracting solution,

[0043] The extract solution is prepared by mixing 95% ethanol solution and 1% citric acid solution according to the volume ratio of 7:3. After adding the extracting solution, place it in a water bath at 50°C for 2 hours. Then the extraction solution was rotary evaporated to obtain 60% of the original volume of the extraction solution. The measured anthocyanin content of black rice is 140mg / 100g, then take 150mL extract, add 25mL extract and dilute to obtain the dilution with anthocyanin content 120mg / 100g.

[0044] (2) Weigh 15g chitosan, add 10mL anhydrous acetic acid and 500mL water to prepare 2% acetic acid solution, add glycerol (6g) with 40% chitosan dry matter weight, and magnetically stir u...

Embodiment 2

[0048] Example 2: Preparation of composite film with purple cabbage as anthocyanin extraction raw material:

[0049] (1) Wash the purple cabbage, shred it and dry it, and grind it into powder with a Chinese herbal medicine grinder. Weigh 10g and add to the extract,

[0050] The extract solution is 75% ethanol solution and 2% citric acid solution, which are mixed according to the volume ratio of 1:1. The mass ratio of the raw material to the extract is 1:20. Add the raw material to the extract and place it in a water bath at 60°C for 3 hours, and then rotate the extract to obtain 50% of the original volume of the extract. . The measured anthocyanin content of purple cabbage is 115.9mg / 100g, then take 150mL extract, add 24mL extract and dilute to obtain a dilution with anthocyanin content of 100mg / 100g.

[0051] (2) Weigh 2g of chitosan, add 5mL of anhydrous acetic acid and 250mL of water to prepare 0.5% acetic acid solution, add glycerol (0.4g) whose mass is 20% of the dry...

Embodiment 3

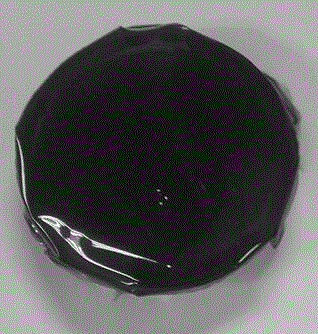

[0053] Example 3: Preparation of composite film with blueberry as raw material for anthocyanin extraction:

[0054] (1) Wash and freeze-dry the blueberries, grind them into powder with a Chinese herbal medicine grinder. Weigh 20g of blueberries and add 200mL of extract,

[0055] The extracting solution is prepared by mixing 80% ethanol solution and 1.5% citric acid solution according to the volume ratio of 8:2. After adding the extracting solution, place it in a water bath at 80°C for 2 hours. Then the extraction solution was rotary evaporated to obtain 60% of the original volume of the extraction solution. If the measured blueberry anthocyanin content is 150mg / 100g, take 150mL of the extract, add 131mL of the extract to dilute, and obtain a dilution with an anthocyanin content of 80mg / 100g.

[0056] (3) Weigh 10g of chitosan, add 10mL of anhydrous acetic acid and 500mL of water to configure a 2% acetic acid solution, add glycerol (3g) whose mass is 30% of the dry matter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com