Paenibacillus ehime hd producing antimicrobial peptides and its application

A technology of bacillus and antimicrobial peptides, applied in the fields of application, antibacterial drugs, antifungal agents, etc., can solve the problem of the lack of reports on the antibacterial properties of Paenibacillus Ehime, general fungal inhibitory effect, and no mention of metabolites, etc. problem, to achieve excellent antifungal activity, good antibacterial effect, simple and easy-to-operate fermentation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

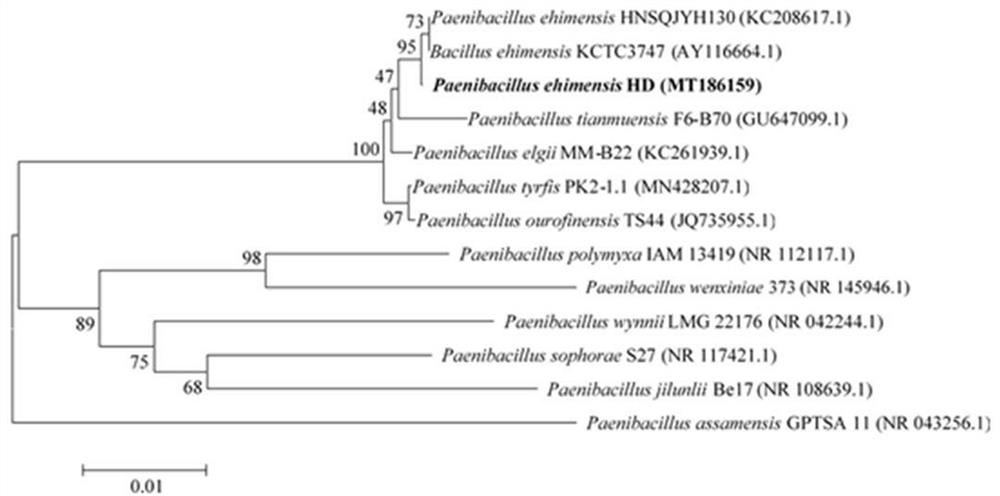

[0033] Example 1 Screening and Identification of Paenibacillus Ehime HD Producing Antimicrobial Peptides

[0034] (1) Isolation and screening of bacterial strains

[0035] More than 40 soil samples were collected from Hebei, Jiangsu and other places. On the nutrient agar medium, the plate antibacterial method was used, Staphylococcus aureus and Penicillium chrysogenum were used as indicator bacteria, and the inhibition zone was used as the basis for screening. Preliminary screening of bacterial strains; after screening, 5 bacterial strains capable of inhibiting the growth of bacteria and fungal indicator bacteria were obtained, respectively numbered as MH, XM, YM, HD and GL; Record the diameter of the inhibition zone to Staphylococcus aureus and Penicillium chrysogenum, the results are shown in Table 1:

[0036] Screening of strains in Table 1

[0037] Strain number Diameter of inhibition zone against Staphylococcus aureus (mm) Diameter of inhibition zone again...

Embodiment 2-7

[0050] The fermentation method of the Paenibacillus ehime HD of embodiment 2-7 producing antimicrobial peptide

[0051] Embodiments 2-7 are respectively a fermentation method of Paenibacillus ehime producing antimicrobial peptides, specifically: after weighing the carbon source, nitrogen source, inorganic salt, and distilled water according to Table 3, mixing, adjusting the pH value, 121 After sterilizing at ℃ for 25 minutes, the improved fermentation medium was prepared; Paenibacillus ehime HD was inoculated into the corresponding improved fermentation medium, and fermented for 18-32 hours at a temperature of 28-32°C and a rotational speed of 220-240r / min ; Their difference only lies in the difference of raw material, consumption, initial pH value and process parameter, specifically see Table 3 for details:

[0052] Table 3 List of fermentation method parameters of Paenibacillus ehime HD producing antimicrobial peptides

[0053]

[0054] Wherein, the fermentation time is ...

Embodiment 8

[0055] Example 8 Effect Identification of the Fermentation Method of Paenibacillus Ehime HD Producing Antimicrobial Peptides

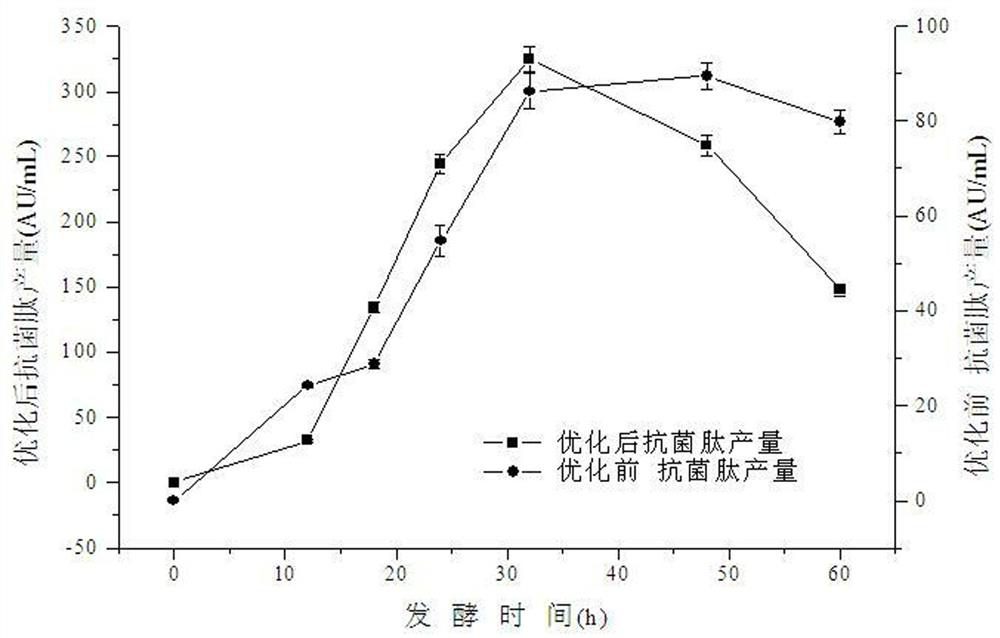

[0056] The fermentation method (after optimization) and the traditional fermentation method (before optimization) of Example 2 were respectively adopted to utilize Paenibacillus ehime HD to carry out long-term fermentation to produce antimicrobial peptides, and the fermentation time 0-60h was recorded every 10h respectively before adopting optimization. / The antimicrobial peptide yield of the post-fermentation method, the results are as follows Figure 4 shown;

[0057] Depend on Figure 4 It can be seen that compared with the traditional fermentation method before optimization, the production of antibacterial peptides by the optimized fermentation method of Example 2 of the present invention is significantly higher at 15-35h of fermentation, and the activity reaches the highest value at 32h of fermentation, compared with that before no optimization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com