Method for preparing chiral amine from multi-enzyme coupled systems

A chiral amine and coupling technology is applied in the field of biocatalytic asymmetric transformation to reduce production costs, solve the problem of coenzyme regeneration, and promote continuous progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of amine dehydrogenase:

[0031] Strain construction, cultivation and collection: Construct the amine dehydrogenase gene shown in SEQIDNO.1, the amine dehydrogenase gene sequence is derived from Bacillusbadius, and use the above amine dehydrogenase gene to prepare the recombinant colon of engineering bacteria expressing amine dehydrogenase Bacillus E.coliBL21(DE3)-adh; Inoculate the above-mentioned engineered bacteria into 200 mL of LB medium with a 1% inoculum amount, and add kanamycin before inoculation to make the final concentration 40 μg / mL. The incubation time was 6 hours at 37° C. with a rotating speed of 200 rpm. The inducer IPTG was added to make the final concentration 10mg / ml, and the culture was continued for 4 hours at 30°C and 200rpm.

[0032] Preparation of crude enzyme solution: the fermented solution obtained after the cultivation was centrifuged in a refrigerated centrifuge (4°C, 8000rpm, 15min) to obtain the cells, the supernatant was ...

Embodiment 2

[0043] 1) Preparation of amine dehydrogenase: same as step 1) of Example 1.

[0044] 2) Preparation of coenzyme regeneration enzyme:

[0045] Formate dehydrogenase:

[0046] Strain construction, cultivation and collection: construct the formate dehydrogenase gene shown in SEQIDNO.3, the formate dehydrogenase gene sequence is derived from Candidaboidinii, and use the above formate dehydrogenase gene to prepare the recombinant large intestine of engineering bacteria expressing formate dehydrogenase Bacillus E.coliBL21(DE3)-fdh; Inoculate the strain into 200mL of LB medium with a 1% inoculation amount, and add kanamycin before inoculation to make the final concentration 40μg / mL. The incubation time was 6 hours at 37° C. with a rotating speed of 200 rpm. The inducer IPTG was added so that the final concentration was 10 mg / ml, and culture was continued for 4 hours at 30° C. and 200 rpm.

[0047] The preparation steps of the crude enzyme solution and the pure enzyme are the same ...

Embodiment 3

[0053] 1) Preparation of amine dehydrogenase: same as step 1) of Example 1.

[0054] 2) Preparation of coenzyme regeneration enzyme: refer to step 2) of Example 1 to obtain glycerol dehydrogenase; refer to step 2) of Example 2 to obtain formate dehydrogenase.

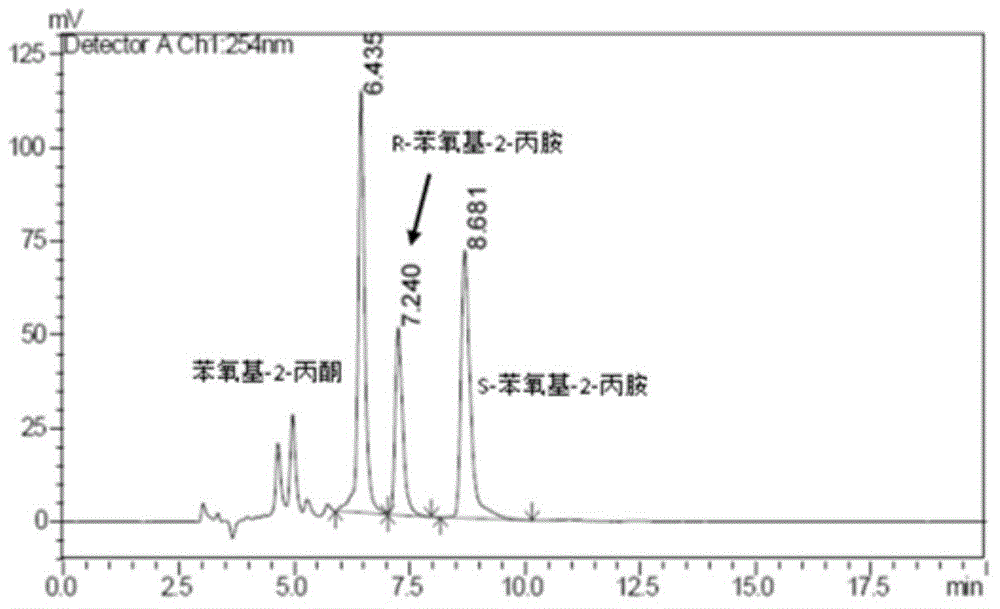

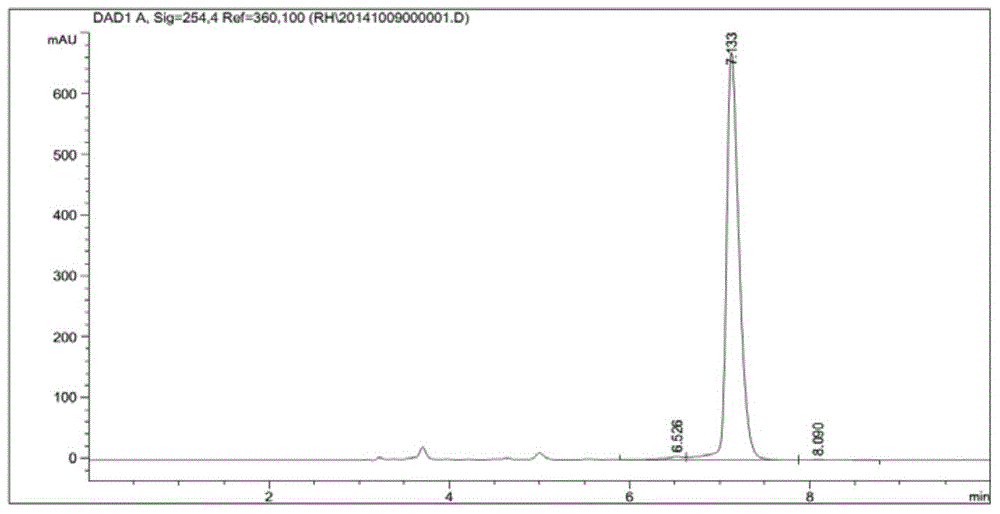

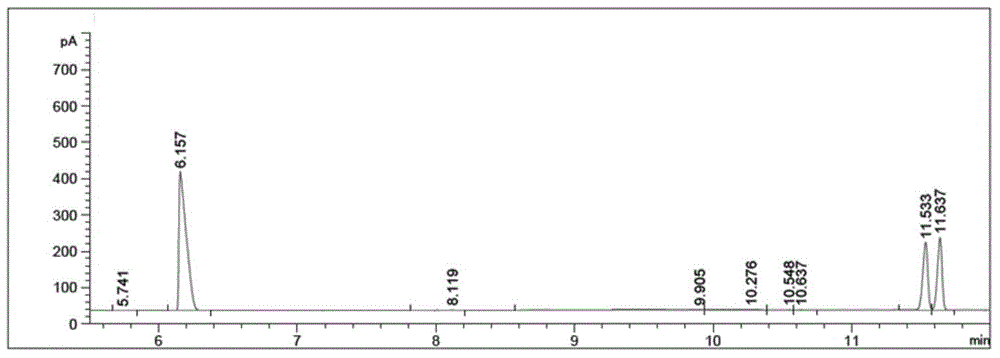

[0055] 3) Using amine dehydrogenase and coenzyme regeneration enzyme to construct a multi-enzyme coupling system, in this example, the amine dehydrogenase-formate dehydrogenase-glycerol dehydrogenase coupling system:

[0056] glycerol, sodium formate and NAD + Soluble in the ammonium chloride-ammonia buffer solution with a concentration of 500mM and a pH value of 8, the addition of glycerol is 2M, the addition of sodium formate is 300mM, NAD + The amount of amine dehydrogenase added is 0.2mM, add amine dehydrogenase enzyme solution, formate dehydrogenase enzyme solution, glycerol dehydrogenase enzyme solution, and make the final concentration of amine dehydrogenase 100U / L, formate dehydrogenase and glycerol dehydrogena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com