Nested V2O3-cladding lithium vanadium phosphate lithium ion anode material

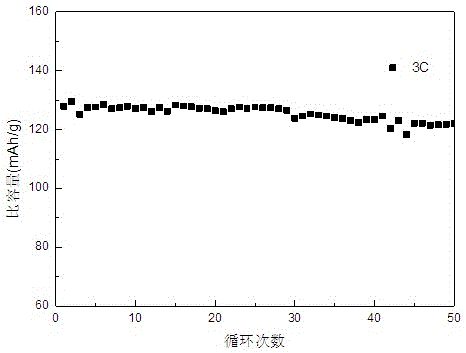

A technology for coating lithium vanadium phosphate and positive electrode materials, which is applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of high sintering temperature and complicated coating process, achieve uniform coating, improve cycle performance, temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] (1) Weigh 12.87g (0.11mol) of ammonium metavanadate, 15.59g (0.15mol) of lithium dihydrogen phosphate, as a source of phosphorus and lithium), 14.50g (0.12mol) of oxalic acid dihydrate, and mix them into 0.37 In L deionized water, the concentration of vanadium ions in the solution is 0.3mol / L; at an ultrasonic frequency of 30kHz and a stirring speed of 250r / min, stir and react for 1h to obtain a mixed solution;

[0034] (2) Spray-dry the mixed solution obtained in step (1), the spray-drying air inlet temperature is 230°C, the spray-drying peristaltic pump speed is 1000rpm / min, the spray-drying fan speed is 100HZ, and a solid powder is obtained;

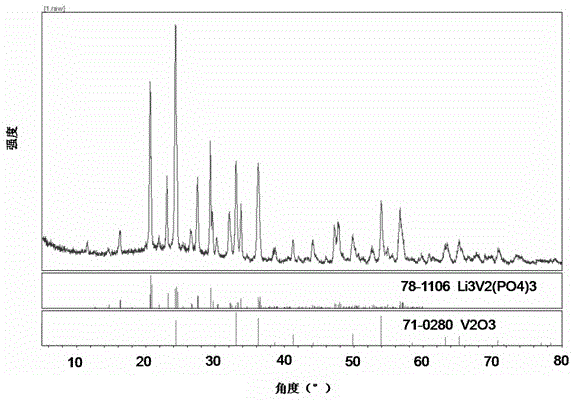

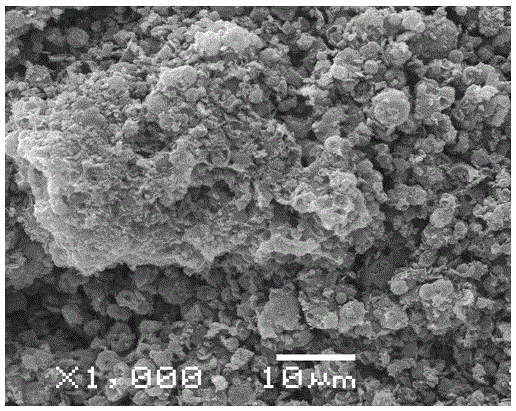

[0035] (3) Under the protection of high-purity argon, the solid powder obtained in step (2) is roasted at 450°C for 5 hours, and then cooled to room temperature with the furnace to obtain the nested V 2 o3 Coated Li 3 V 2 (PO 4 ) 3 lithium-ion cathode material. where ...

Embodiment 2

[0042] This embodiment includes the following steps:

[0043] (1) Weigh 6.43g (0.055mol) of ammonium metavanadate, 4.55g (0.0275mol) of vanadium pentoxide, 3.59g (0.15mol) of lithium hydroxide, 17.25g (0.15mol) of ammonium dihydrogen phosphate, 1.38 formic acid g (0.03mol), 10.08g (0.08mol) of oxalic acid dihydrate; mix them into 0.525L deionized water; stir and react for 1.5h at an ultrasonic frequency of 20kHz and a stirring speed of 100r / min to obtain a mixed solution;

[0044] (2) Spray-dry the mixed solution obtained in step (1), the spray-drying air inlet temperature is 200°C, the spray-drying peristaltic pump speed is 500rpm / min, the spray-drying fan speed is 40HZ, and a solid powder is obtained;

[0045] (3) Under the protection of high-purity hydrogen / argon mixed gas (hydrogen volume concentration is 5%), the solid powder obtained in step (2) is roasted at 500 ° C for 6 hours, and then cooled to room temperature with the furnace to obtain nested V 2 o 3 Coated Li 3...

Embodiment 3

[0049] This embodiment includes the following steps:

[0050] (1) Weigh 10.91g (0.06mol) of vanadium pentoxide, 5.54g (0.075mol) of lithium carbonate, 17.25g (0.15mol) of ammonium dihydrogen phosphate, and 18.99g (0.15mol) of oxalic acid dihydrate, and mix them into 0.3L deionized water; at an ultrasonic frequency of 40kHz and a stirring speed of 400r / min, stir and react for 2h to obtain a mixed solution;

[0051] (2) Spray-dry the solution obtained in step (1), the temperature of the spray-drying air inlet is 260°C, the speed of the spray-drying peristaltic pump is 1800rpm / min, and the speed of the spray-drying fan is 150HZ to obtain a solid powder;

[0052] (3) Under the protection of high-purity argon, the solid powder obtained in step (2) is roasted at 500 ° C for 6 hours, and then cooled to room temperature with the furnace to obtain nested V 2 o 3 Coated Li 3 V 2 (PO 4 ) 3 lithium-ion cathode material. where V 2 o 3 relative Li 3 V 2 (PO 4 ) 3 The mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com