Preparation method for support-type tubular palladium membrane or palladium alloy membrane

A palladium alloy membrane and supporting technology, which is applied in the field of hydrogen purification, can solve the problems of long production cycle, low adhesion, and high technical difficulty, and achieve the effect of overcoming poor adhesion, poor mechanical strength, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

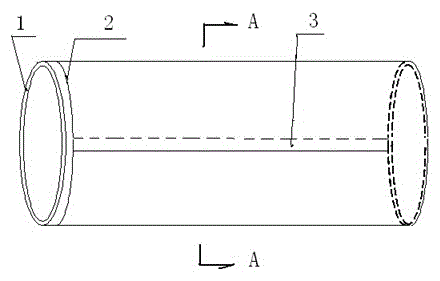

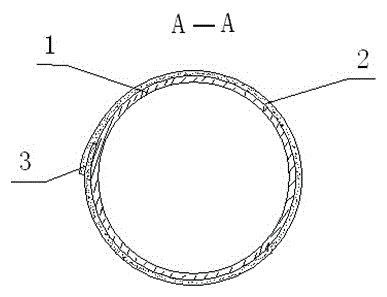

[0028] Example 1 Be the basic embodiment of the preparation method of a kind of support type tubular palladium film of the present invention, palladium alloy film, its step is as follows:

[0029] A. Select a porous tubular support 1, and then tightly cover the surface of the tubular support 1 with a palladium film or palladium alloy film 2, leaving an overlap of 1 to 3 mm as the bonding layer 3. The excess part is cropped and removed;

[0030] B, bonding the bonding layer 3 with an inorganic adhesive, so that the palladium film or the palladium alloy film 2 forms a complete cylindrical support-type tubular palladium film or palladium alloy film tube;

[0031] C. Place the supported tubular palladium membrane or palladium alloy membrane tube in step B in an oven, then gradually raise the temperature in the oven from room temperature to 80-150°C, keep warm for 2-5 hours, and then cool down to room temperature naturally to make the adhesive The agent is fully cured and has hi...

Embodiment 2

[0032] Example 2 : For further embodiment: the preparation method of described support type tubular palladium membrane, palladium alloy membrane, its tubular support body 1 is that the tube wall is porous stainless steel thin wall tube, or the sieve of multi-mesh hole is made screen tube. The palladium film or palladium alloy film 2 is a palladium film or palladium alloy film prepared by melt casting and cold rolling. The outer diameter of the stainless steel thin-walled pipe or screen pipe is 2-20mm, the thickness of the pipe wall is 0.5-5mm, and the pipe length is 50-800mm. If the pipe length is too short or too long, it is not conducive to construction; The average diameter is 5-100um. The thickness of the palladium film or palladium alloy film 2 is 10-100um. The palladium membrane is a pure palladium membrane. In the step B, the inorganic adhesive is a one-component inorganic adhesive with high temperature resistance, selected from one-component silicate or phosphate ...

Embodiment 3

[0033] Example 3 : For further embodiment: the preparation method of described supported tubular palladium film, palladium alloy film, described palladium alloy film is palladium-silver alloy film, or palladium-copper alloy film, or palladium-gold alloy film , or palladium-yttrium alloy film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com