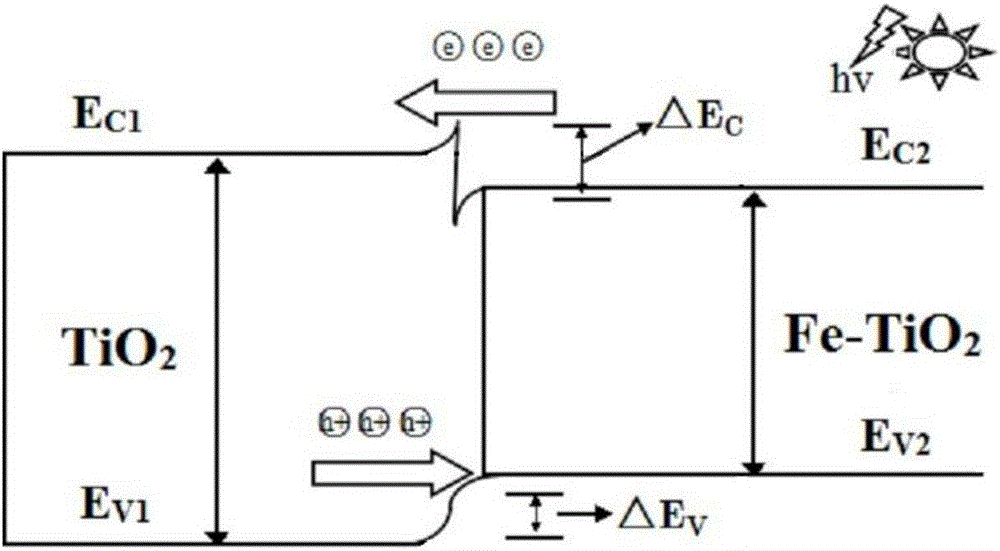

Preparation method of nanometer composite photocatalyst TiO2/Fe-TiO2 with P-N junction structure

A nanocomposite and photocatalyst technology, applied in the field of nanocomposite photocatalyst and photocatalyst material preparation, can solve the problems of high photogenerated electron-hole recombination rate and poor visible light absorption rate, etc., and achieve good stability and catalytic activity. Conducive to environmental protection, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Mix butyl titanate solution and absolute ethanol solution at a molar ratio of 1:35, adjust the pH of the mixed solution to 3 with nitric acid, transfer the mixed solution to a hydrothermal kettle, the hydrothermal reaction temperature is 200°C, water TiO was prepared by thermal reaction for 24h 2 Nano powder; the above reaction parameters remain unchanged, and Fe-TiO is prepared from ferric nitrate according to the molar percentage of 0.2% Fe / Ti 2 Nano powder.

[0038] (2) The two kinds of nano photocatalytic powders were washed with absolute ethanol and water three times respectively, dried at 70°C for 12h, ground, and the powders were heat-treated at 450°C in a muffle furnace for 2h.

[0039] (3) Fe-TiO 2 with TiO 2 Two kinds of nano-powders were mixed at a ratio of 8:100 by weight, and ultrasonically dispersed in distilled water for 30 minutes at room temperature. Among them, TiO 2 The mass volume ratio with distilled water is 1:10. After ultrasonication, the...

Embodiment 2

[0041] (1) Mix butyl titanate solution and absolute ethanol solution at a molar ratio of 1:35, adjust the pH of the mixed solution to 3 with nitric acid, transfer the mixed solution to a hydrothermal kettle, the hydrothermal reaction temperature is 200°C, water TiO was prepared by thermal reaction for 16h 2 Nano powder; the above reaction parameters remain unchanged, and Fe-TiO is prepared from ferric nitrate according to 0.5% Fe / Ti molar percentage 2 Nano powder.

[0042] (2) The two kinds of nano photocatalytic powders were washed with absolute ethanol and water three times respectively, dried at 70°C for 12h, ground, and the powders were heat-treated at 450°C in a muffle furnace for 2h.

[0043] (3) Fe-TiO 2 with TiO 2 Two kinds of nano-powders were mixed at 7.7:100 by weight percentage, and ultrasonically dispersed in distilled water for 30 minutes at room temperature, wherein TiO 2 The mass volume ratio with distilled water is 1.2:10. After ultrasonication, the powder...

Embodiment 3

[0045] (1) Mix butyl titanate solution and absolute ethanol solution at a molar ratio of 1:35, adjust the pH of the mixed solution to 3 with hydrochloric acid, transfer the mixed solution to a hydrothermal kettle, the hydrothermal reaction temperature is 160°C, and water TiO was prepared by thermal reaction for 16h 2 Nano powder; the above reaction parameters remain unchanged, and Fe-TiO is prepared from ferric nitrate according to the molar percentage of 0.2% Fe / Ti 2 Nano powder.

[0046] (2) The two kinds of nano photocatalytic powders were washed with absolute ethanol and water three times respectively, dried at 70°C for 12h, ground, and the powders were heat-treated at 450°C in a muffle furnace for 2h.

[0047] (3) Fe-TiO 2 with TiO 2 Two kinds of nano-powders were mixed at 7.7:100 by weight percentage, and ultrasonically dispersed in distilled water for 30 minutes at room temperature, wherein TiO 2 The mass volume ratio with distilled water is 1.5:10. After ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com