Preparation method of black phosphorus alkene-graphene composite material hollow microsphere

A technology of composite materials and hollow microspheres, applied in the preparation of phosphorus, etc., can solve problems such as affecting electrical properties and reducing electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

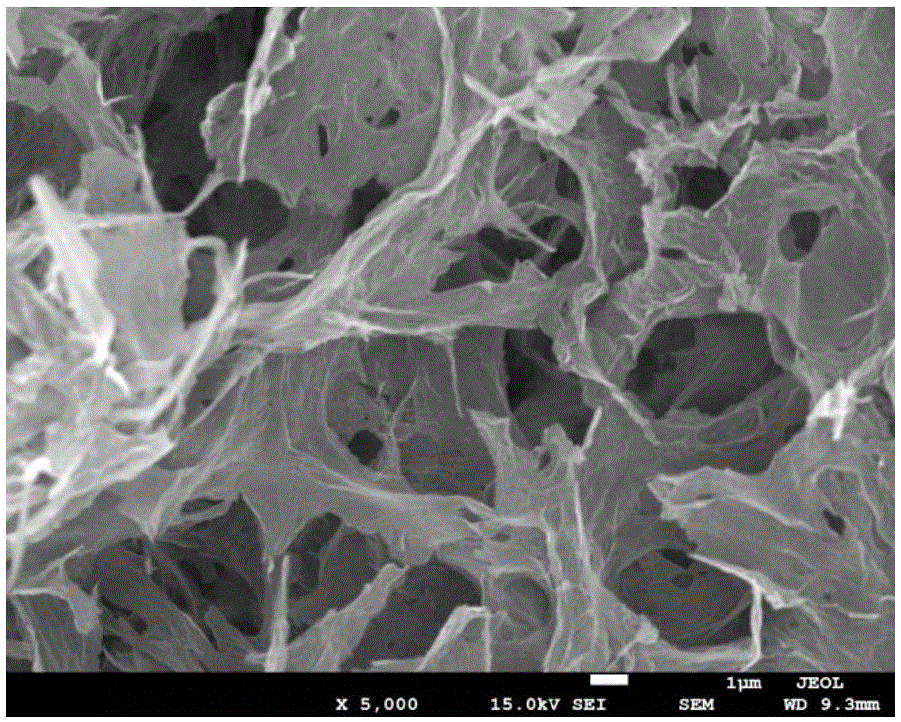

Image

Examples

Embodiment 1

[0016] (1) First, add the ethanol dispersion of 0.01mg / mL black phosphorene nanosheets to the ethanol dispersion of 0.5mg / mL graphene oxide nanosheets, and use mechanical stirring to make both black phosphorene and graphene oxide mix. When mixing black phosphorene and graphene, the same solvent should be used, and the volume ratio of the two should be 1:1.

[0017] (2) Spray the mixed dispersion of black phosphorene and graphene oxide into liquid helium through a sprayer with a nozzle diameter of 0.05mm and freeze it into microspheres quickly, and then freeze the obtained black phosphorene and graphene oxide composite material The microspheres were freeze-dried in a freeze dryer for 6 hours to obtain hollow microspheres of black phosphorene and graphene oxide composite material.

[0018] (3) Finally, the graphene oxide was reduced to graphene at 500°C under the condition of nitrogen protection at high temperature, and finally the black phosphorene and graphene composite hollo...

Embodiment 2

[0020] (1) First, add 1 mg / mL dimethyl sulfoxide dispersion of black phosphorene quantum dots to 0.5 mg / mL graphene oxide nanosheet dimethyl sulfoxide dispersion, and use mechanical stirring to make black phosphorus A mixture of both ene and graphene oxide. When mixing black phosphorene and graphene, the same solvent should be used, and the volume ratio of the two should be 1:1.

[0021] (2) Spray the mixed dispersion of black phosphorene and graphene oxide into liquid helium through a sprayer with a nozzle diameter of 0.2mm to rapidly freeze into microspheres, and then freeze the obtained black phosphorene and graphene oxide composite material The microspheres were freeze-dried in a freeze dryer for 24 hours to obtain hollow microspheres of black phosphorene and graphene oxide composite material.

[0022] (3) Finally, the graphene oxide was reduced to graphene at 800°C under the protection of argon gas at high temperature, and the hollow microspheres of black phosphorene and...

Embodiment 3

[0025] (1) First, add the N-methylpyrrolidone dispersion of 2mg / mL black phosphorene quantum dots to the N-methylpyrrolidone dispersion of 1mg / mL graphene oxide nanosheets, and use mechanical stirring to make the black phosphorene mixed with graphene oxide. When mixing black phosphorene and graphene, the same solvent should be used, and the volume ratio of the two should be 1:1.

[0026] (2) Spray the mixed dispersion of black phosphorene and graphene oxide into liquid helium through a sprayer with a nozzle diameter of 0.3mm and freeze it rapidly into microspheres, and then freeze the obtained black phosphorene and graphene oxide composite material The microspheres were freeze-dried in a freeze dryer for 36 hours to obtain black phosphorene and graphene oxide composite hollow microspheres.

[0027] (3) Finally, the graphene oxide was reduced to graphene at 1000°C under the protection of argon at high temperature, and the hollow microspheres of black phosphorene and graphene c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com