Resol-assisted synthetic large aperture ordered mesopore metallic oxide material and preparation method of material

A phenolic resin prepolymerization, large pore size technology, applied in chemical instruments and methods, tin oxide, tungsten oxide/tungsten hydroxide, etc., can solve problems such as narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

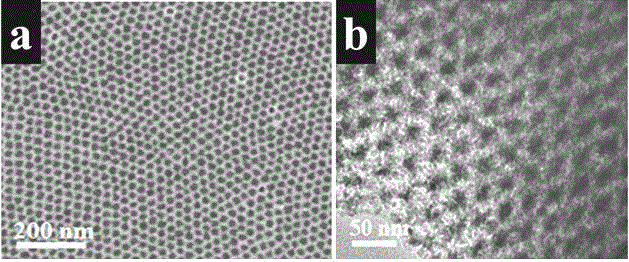

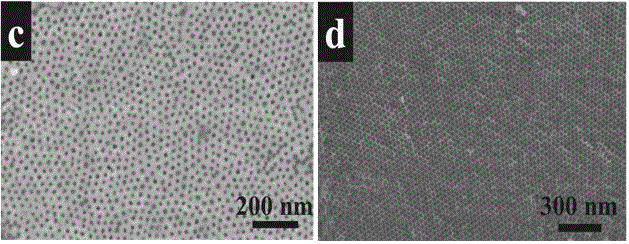

Image

Examples

Embodiment 1

[0022] Example 1: Synthesis of mesoporous tungsten oxide material with high specific surface area

[0023] 0.10g PEO-b-PS (M n =18500gmol -1 ) into 5.0g THF solution, stirred to obtain a uniform solution (2.0wt%), added 0.3g concentrated hydrochloric acid (37wt%) and 0.5g resol THF solution (20wt%) and stirred evenly, then added 0.3gWCl 6 , stirred for 2h, the solution gradually changed from orange to ink blue.

[0024] The solution was transferred to a petri dish and volatilized at room temperature for 60 minutes to turn dark blue. The petri dish was transferred to an oven at 70°C to further volatilize the solvent and cured for 48 hours to obtain a blue transparent composite film. The composite film was scraped off from the Petri dish to obtain a blue powder.

[0025] Put the newly prepared sample in a tube furnace, and bake it at 350°C for 3h under a nitrogen atmosphere, with a heating rate of 1.0°C / min, to obtain gray-black WO 3 / C Composite. Then, the obtained sample ...

Embodiment 2

[0026] Example 2: Synthesis of mesoporous tin oxide material with high specific surface area

[0027] 0.10g PEO-b-PMMA (M n =24700gmol -1 ) was dissolved in 5.0g of THF solution, 0.4g of resol in THF solution (10wt%) was added, and after stirring for 30min, a uniform solution (2.0wt%) was obtained. 0.6g of SnCl 4 Dissolve in 0.9g of acetylacetone (AcAc) solution, stir for 30min, then mix the two solutions, add 0.6g of concentrated hydrochloric acid (37wt%), stir for 30min, and obtain a light red transparent solution.

[0028] The solution was transferred to a petri dish, and after 10 minutes of volatilization at room temperature, the petri dish was transferred to a 40°C oven to further volatilize the solvent for 24 hours, and then the temperature of the oven was raised to 100°C to cure for 24 hours to obtain a light yellow transparent composite film. The film was scraped off the Petri dish to give a pale yellow powder.

[0029] Put the as-made sample in a tube furnace and ...

Embodiment 3

[0030] Example 3: Synthesis of mesoporous niobium oxide material with high specific surface area

[0031] 0.24gNbCl 5 Dissolve in 2.16gTHF, and then add a few drops of nitric acid to promote its dissolution. Next, add 0.6gresol THF solution (mass fraction is 30%) and 5.0gPEO-b-PS (M n =32500gmol -1 ) THF solution (mass fraction is 2%, 0.1gPEO-b-PS dissolved in 4.9gTHF). After mixing evenly, 0.25 g of nitric acid and 5 g of THF were added, and magnetically stirred for one hour to obtain an orange solution.

[0032] The solution was transferred to a Petri dish, and after volatilization at room temperature for 2 hours, the Petri dish was transferred to an oven at 50°C for further volatilization of the solvent for 12 hours, and then the temperature of the oven was raised to 150°C for curing for 48 hours to obtain an orange transparent composite film. The membrane was scraped from the Petri dish and ground to an orange powder.

[0033] The freshly prepared samples were placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com