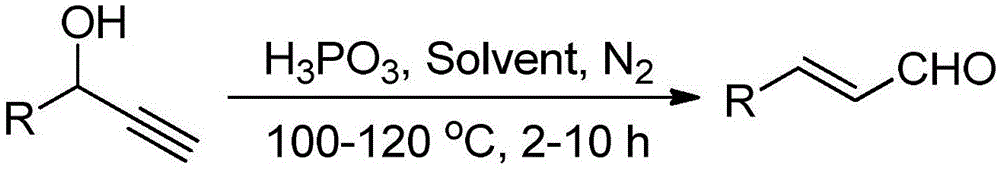

Method for preparing cinnamyl aldehyde compounds

A compound, the technology of cinnamaldehyde, which is applied in the field of preparation of cinnamaldehyde compounds, can solve the problems of pretreatment and preparation of catalysts, and achieve the effects of easy separation, high yield, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

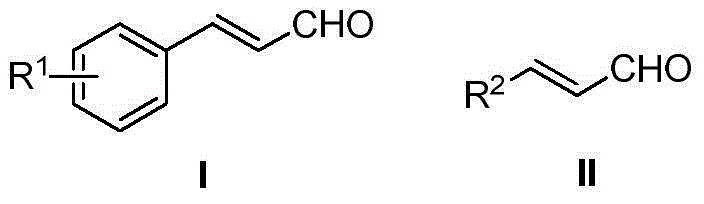

Examples

Synthetic example 1

[0021] Synthesis of Cinnamaldehyde

[0022] Add 0.2mmol 1-phenyl-2-propyn-1-ol, 0.30mmol 50wt% phosphorous acid aqueous solution, and 0.5mL dichloromethane into the reactor. Under nitrogen atmosphere, heat to 110°C, keep stirring for 2h, stop the reaction, cool to room temperature, add saturated sodium carbonate solution to wash, extract with dichloromethane, dry, distill off the solvent under reduced pressure, and separate the crude product by column chromatography to obtain Target product, yield 91%. 1 HNMR (400MHz, CDCl 3 ):δ9.70(d,J=7.7Hz,1H),7.57-7.55(m,2H),7.49-7.42(m,4H),6.72(dd,J=16.0,7.7Hz,1H). 13 CNMR (100MHz, CDCl 3 ): δ193.6, 152.7, 133.9, 131.2, 129.0, 128.5, 128.4.

Synthetic example 2

[0024] Synthesis of p-fluorocinnamaldehyde

[0025] Add 0.2mmol of 1-p-fluorophenyl-2-propyn-1-ol, 0.30mmol of 50wt% phosphorous acid aqueous solution, and 0.5mL of dichloromethane into the reactor. Under nitrogen atmosphere, heat to 110°C, keep stirring for 2h, stop the reaction, cool to room temperature, add saturated sodium carbonate solution to wash, extract with dichloromethane, dry, distill off the solvent under reduced pressure, and separate the crude product by column chromatography to obtain Target product, yield 88%. 1 HNMR (400MHz, CDCl 3 ): δ9.69(d, J=7.6Hz, 1H), 7.59-7.54(m, 2H), 7.44(d, J=16.0Hz, 1H), 7.15-7.09(m, 2H), 6.65(dd, J=16.0,7.6Hz,1H). 13 CNMR (100MHz, CDCl 3 ):δ193.4,165.42(d,J C-F =253.2Hz), 151.3, 130.4(d, J C-F =8.7Hz), 130.2(d, J C-F =3.4Hz), 128.3(d, J C-F =2.3Hz), 116.3(d, J C-F =22.1Hz).

Synthetic example 3

[0027] Synthesis of p-chlorocinnamaldehyde

[0028]Add 0.2mmol of 1-p-chlorophenyl-2-propyn-1-ol, 0.30mmol of 50wt% phosphorous acid aqueous solution, and 0.5mL of dichloromethane into the reactor. Under nitrogen atmosphere, heat to 110°C, keep stirring for 2h, stop the reaction, cool to room temperature, add saturated sodium carbonate solution to wash, extract with dichloromethane, dry, distill off the solvent under reduced pressure, and separate the crude product by column chromatography to obtain Target product, yield 85%. 1 HNMR (400MHz, CDCl 3 ):δ9.70(d,J=7.6Hz,1H),7.50(d,J=8.5Hz,2H),7.45-7.40(m,3H),6.69(dd,J=16.0,7.6Hz,1H) . 13 CNMR (100MHz, CDCl 3 ): δ193.3, 151.0, 137.2, 132.4, 129.6, 129.4, 128.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com