Bulk absorption type solar selective heat absorption paint and preparation method and application thereof

A technology of heat-absorbing paint and solar energy, applied in the direction of radiation-absorbing paint, coating, etc., can solve the problem of high thermal emissivity, and achieve the effect of low thermal emissivity, prominent thermal absorption rate, and reduced thermal emissivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Preparation of solar energy selective heat-absorbing coating

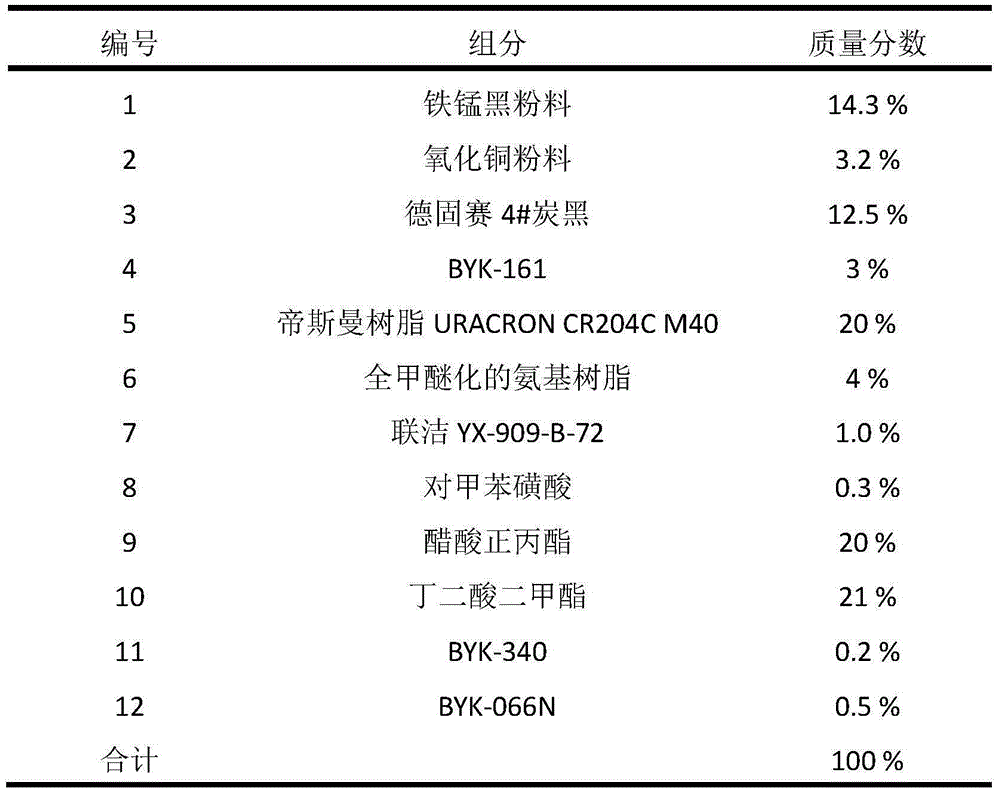

[0035] The basic formula is shown in Table 1, and the specific preparation method is as follows:

[0036] Add dispersant BYK-161 to part of n-propyl acetate and dimethyl succinate, stir well to dissolve. Add iron-manganese black powder, copper oxide powder, and Degussa 4# carbon black to the above mixed solution, stir and disperse for 2 hours, grind to the specified fineness with a sand mill, and prepare carbon black-iron-manganese black composite slurry material; then add DSM resin URACRONCR204CM40, fully etherified amino resin, p-toluenesulfonic acid, Lianjie YX-909-B-72, the remaining n-propyl acetate and dimethyl succinate to the above In the carbon black-iron manganese black composite slurry, disperse at high speed for 1 hour; then add leveling agent BYK-340 and defoamer BYK-066N, and disperse at high speed for 0.5 hour to obtain a coating.

[0037] The formula of table 1 solar energy se...

Embodiment 2

[0039] Embodiment 2: Preparation of solar energy selective heat-absorbing coating

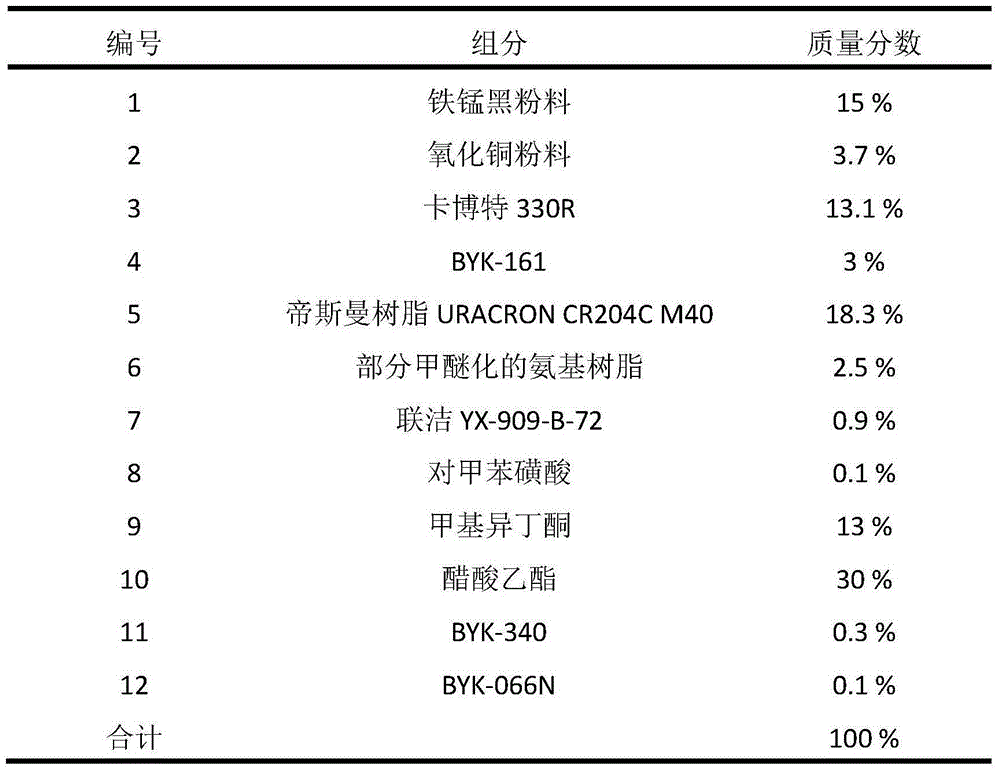

[0040] The basic formula is shown in Table 2, and the specific preparation method is as follows:

[0041]Add dispersant BYK-161 to part of methyl isobutyl ketone and ethyl acetate, stir evenly to dissolve it. Add iron-manganese black powder, copper oxide powder, and Cabot 330R to the above mixed solution, stir and disperse for 2 hours, grind to a specified fineness with a sand mill, and prepare carbon black-iron-manganese black composite slurry; Add DSM resin URACRONCR204CM40, partially methylated amino resin, p-toluenesulfonic acid, Lianjie YX-909-B-72, the remaining methyl isobutyl ketone and ethyl acetate to the above carbon black-iron manganese In the black composite slurry, disperse at a high speed for 1 hour; then add leveling agent BYK-340 and defoamer BYK-066N, and disperse at a high speed for 0.5 hours to obtain a coating.

[0042] Table 2 The formula of solar energy selective heat-a...

Embodiment 3

[0044] Embodiment 3: Preparation of solar energy selective heat-absorbing coating

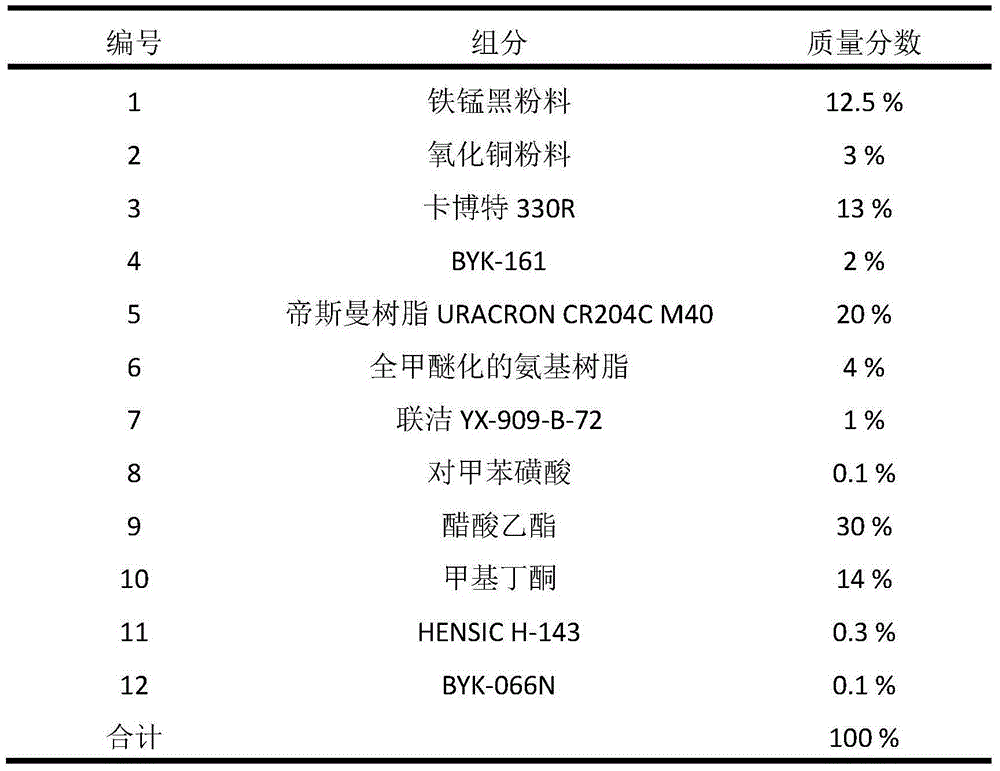

[0045] The basic formula is shown in Table 3, and the specific preparation method is as follows:

[0046] Add dispersant BYK-161 to part of ethyl acetate and methyl butanone, stir well to dissolve. Add iron-manganese black powder, copper oxide powder, and Cabot 330R to the above mixed solution, stir and disperse for 2 hours, grind to a specified fineness with a sand mill, and prepare carbon black-iron-manganese black composite slurry; Add DSM resin URACRONCR204CM40, partially methylated amino resin, p-toluenesulfonic acid, Lianjie YX-909-B-72, the remaining ethyl acetate and methyl butanone to the above carbon black - iron manganese black In the composite slurry, disperse at high speed for 1 hour; then add leveling agent HENSICH-143 and defoamer BYK-066N, and disperse at high speed for 0.5 hours to obtain a coating.

[0047] Formulation of table 3 solar energy selective heat-absorbing coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com