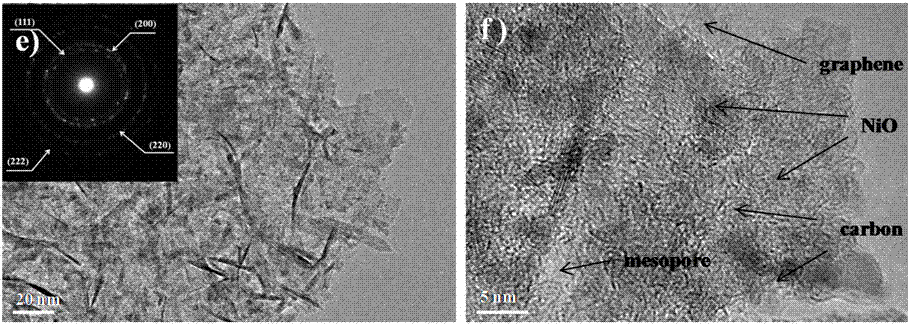

Carbon-coated nickel oxide nanosheets supported on graphene nanocomposite and preparation method thereof

A nanocomposite material, graphene technology, applied in the field of lithium battery negative electrode material and its preparation, can solve the problems of complex preparation process, difficult to obtain a uniform structure, etc., to promote diffusion, good stability of multiple charge and discharge, outstanding performance Effect of magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028](1) Pour 600 ml of commercially available tetrahydrofuran into a 1000 ml flask, add 15 g of calcium hydride, then stir at room temperature for 24 h, then distill off the solvent at 70°C to obtain anhydrous tetrahydrofuran;

[0029] (2) The graphene oxide (GO) aqueous dispersion prepared by the improved Hummers method was centrifuged with an anhydrous solvent obtained by adding one step six times to obtain an anhydrous tetrahydrofuran dispersion of GO, and the concentration of GO was 7.5 mg / ml;

[0030] (3) Weigh 0.105 g of bis(cyclopentadiene)nickel and add it to 8 ml of anhydrous tetrahydrofuran, sonicate for 10 min to fully dissolve the bis(cyclopentadiene)nickel; then add 2 ml of GO in anhydrous solvent dispersion , sonicated for 30 min to help disperse; then the mixture was transferred to a 25 ml autoclave, and placed in an oven at 210°C for 24 h; after naturally cooling to room temperature, the material liquid was taken out and washed 5 times by centrifugation with a...

Embodiment 2

[0034] (1) Pour 600 ml of commercially available tetrahydrofuran into a 1000 ml flask, add 15 g of calcium hydride, then stir at room temperature for 24 h, then distill off the solvent at 70°C to obtain anhydrous tetrahydrofuran;

[0035] (2) Weigh 0.150 g of bis(cyclopentadiene) nickel and add it to 10 ml of anhydrous tetrahydrofuran, sonicate for 10 min to fully dissolve the bis(cyclopentadiene) nickel; then transfer the mixture to a 25 ml autoclave placed in an oven at 210°C for 24 hours; after naturally cooling to room temperature, the feed liquid was taken out and washed with absolute ethanol for 5 times; then the reactants were dried in an oven at 60°C for 12 hours;

[0036] (4) Take 0.5 g of dried powder and place it in a tube furnace; heat it up to 320 °C for 2.5 h at a rate of 5 °C / min in an air atmosphere, and then cool naturally to obtain the final NiO@Carbon nanocomposite material.

[0037] From Figure 6 It can be seen that the NiO@Carbon obtained by adding only ...

Embodiment 3

[0039] (1) Pour 600 ml of commercially available tetrahydrofuran into a 1000 ml flask, add 15 g of calcium hydride, then stir at room temperature for 24 h, then distill off the solvent at 70°C to obtain anhydrous tetrahydrofuran;

[0040] (2) The graphene oxide (GO) aqueous dispersion prepared by the improved Hummers method was centrifuged with an anhydrous solvent obtained by adding one step six times to obtain an anhydrous tetrahydrofuran dispersion of GO, and the concentration of GO was 7.5 mg / ml;

[0041] (3) Weigh 0.045 g of bis(cyclopentadiene)nickel and add it to 8 ml of anhydrous tetrahydrofuran, sonicate for 10 min to fully dissolve the bis(cyclopentadiene)nickel; then add 2 ml of anhydrous solvent dispersion of GO , sonicated for 30 min to help disperse; then the mixture was transferred to a 25 ml autoclave, and placed in an oven at 210°C for 24 h; after naturally cooling to room temperature, the material liquid was taken out and washed 5 times by centrifugation with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com