Three-dimensional porous MnO/C-N nano-composite material based on rape pollen, preparing method thereof and application thereof

A nanocomposite material and three-dimensional porous technology are applied to three-dimensional porous MnO/C-N nanocomposite materials based on rape pollen and their preparation and application fields, which can solve problems such as limitations and achieve low cost, simple preparation method and stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

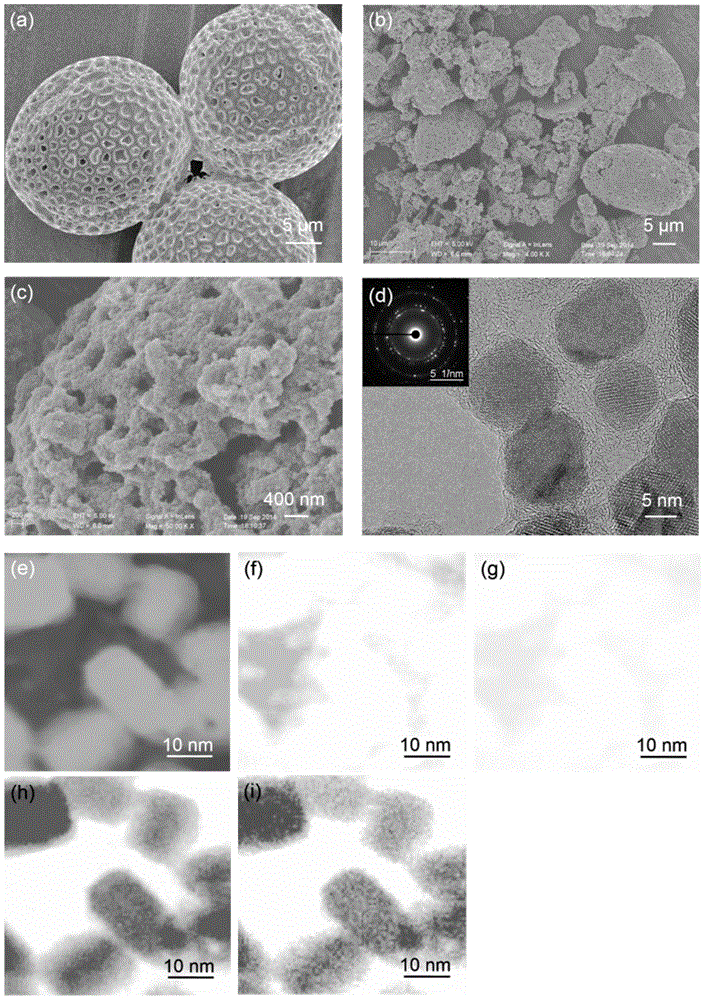

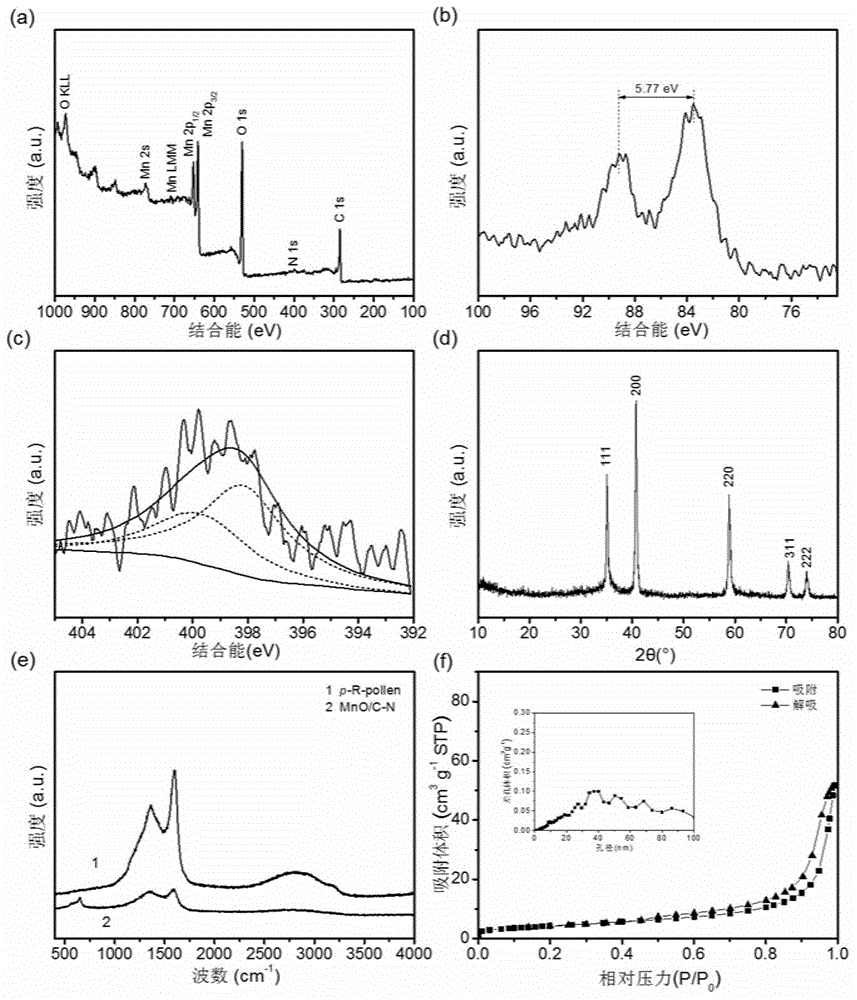

[0029] This embodiment prepares the MnO / C-N nanocomposite material according to the following steps:

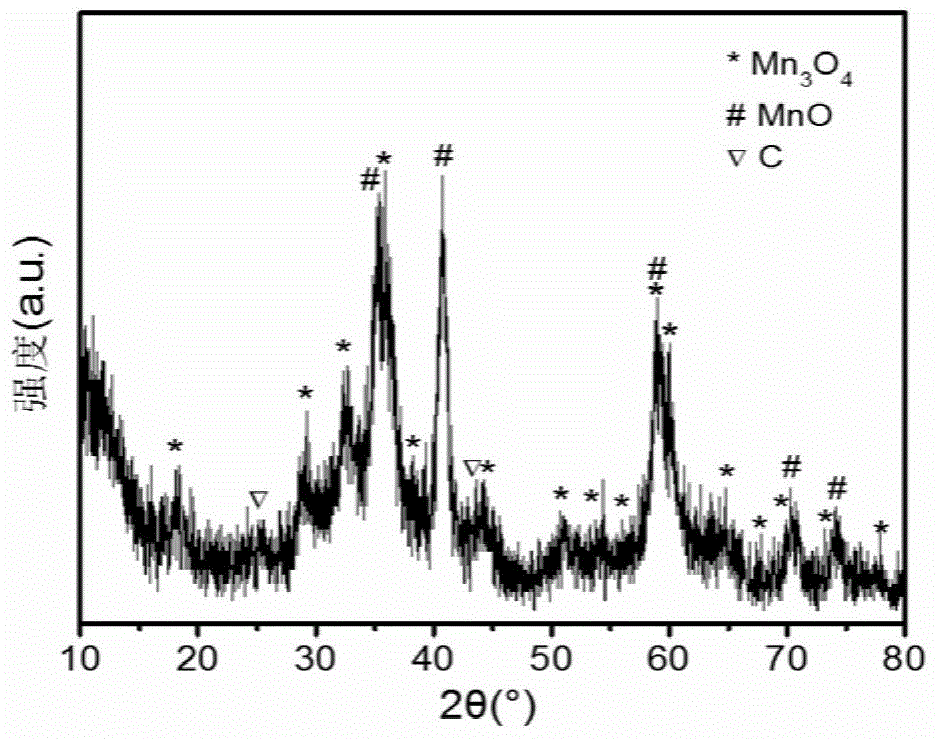

[0030] At room temperature, weigh a quantitative amount of KMnO 4 , add 250.0mL deionized water to dissolve, and obtain KMnO with a concentration of 0.225mol / L 4 solution; 4 g rapeseed pollen was dispersed in KMnO 4 solution, stirred at room temperature for 8 hours. Then filter the product, wash it once with deionized water and ethanol, and then dry it under vacuum at 80°C; finally, it was calcined at 500°C for 15.0°C under an argon atmosphere with 5% hydrogen to obtain the product MnO / C-N nanocomposite material, Labeled as MnO / C-N.

[0031] In order to compare the influence of stirring time, high-temperature calcination temperature and high-temperature calcination time on the product, a comparison sample was prepared in the same way as above, and the comparison sample was marked as MnO / C-N-x-y-z, where the values of x, y, and z were respectively the values of the comp...

Embodiment 2

[0042] In this embodiment, the sample prepared in embodiment 1 is used to assemble lithium batteries according to the following steps:

[0043] Each sample prepared in Example 1 and pyrolysis pollen (p-R-pollen) were dissolved in n-methyl-2-pyrrolidone with acetylene black and polyvinylidene fluoride at a mass ratio of 8:1:1, and then spread to Electrodes are formed on the copper foil. The electrode was dried at 80° C. for 12.0 hours under vacuum conditions, and then the above electrode was rolled, cut into a circle with a diameter of 1.0 cm, and placed in a pure argon glove box. The metal lithium foil is used as the auxiliary electrode, the glass fiber is used as the separator, and the concentration of LiPF is 1.0MLiPF at a mass percentage of 1:1:1. 6 The electrolytes of ethylene carbonate, dimethyl carbonate, and diethyl carbonate were used as materials, and button cells were assembled in a glove box.

[0044] Such as Figure 6 As shown in (a), compared to cells assembled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com