Three-dimensional anode material for hydrogen production by water electrolysis and preparation method of three-dimensional anode material

An anode material and water electrolysis technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems that are not suitable for the controllable preparation of multi-component nanostructured oxygen evolution electrodes, achieve controllable structural components, and improve utilization , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

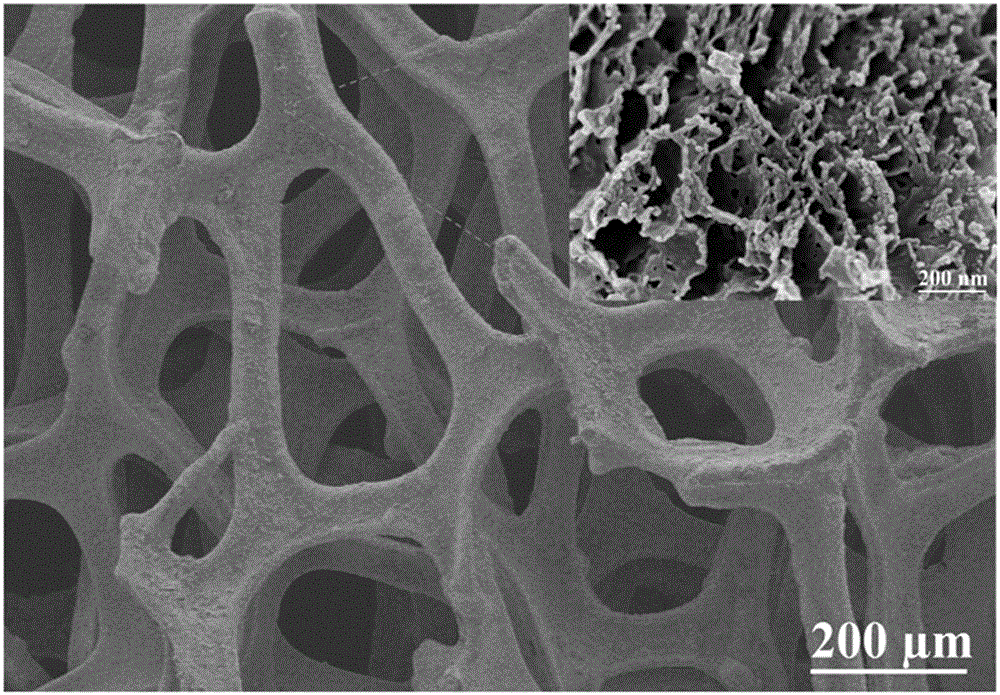

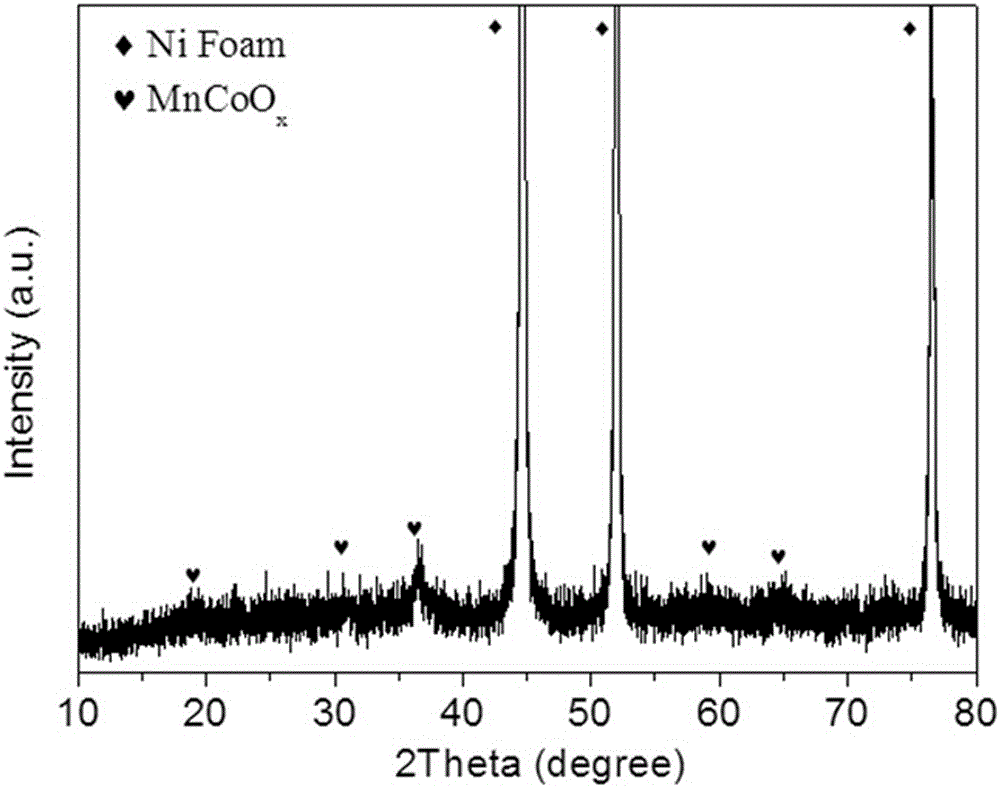

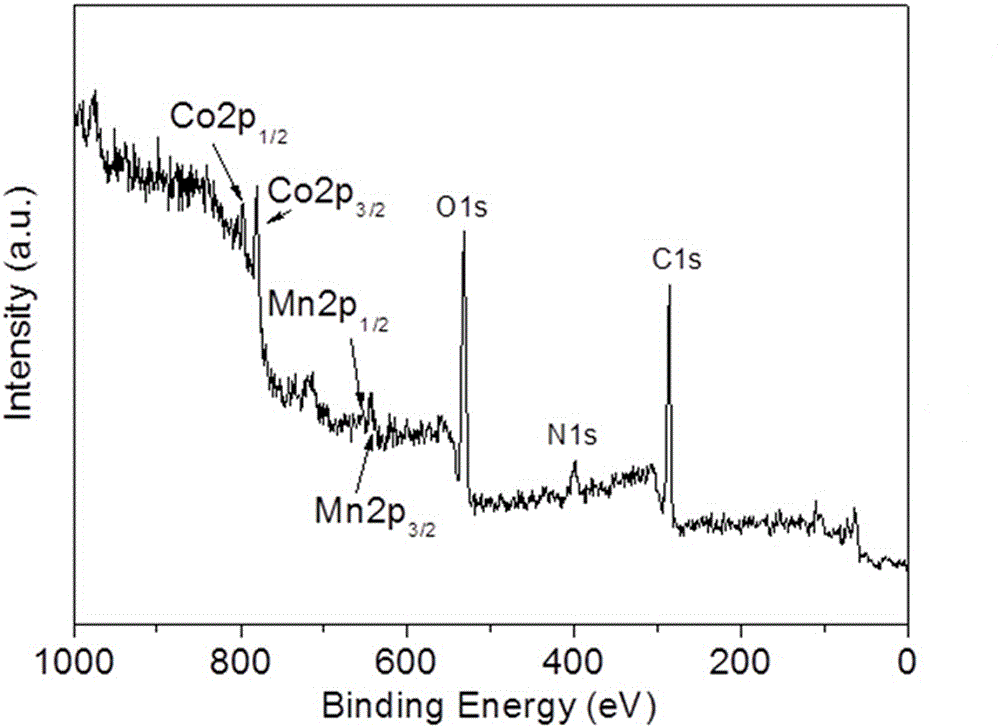

[0031] A new three-dimensional anode material for hydrogen production by electrolysis of water, including nitrogen-doped carbon / transition metal manganese-cobalt oxide supported on nickel foam and its three-dimensional anode sheet for hydrogen production by electrolysis of water, using a liquid-solid synthesis method In situ preparation, the specific steps are:

[0032] (1) Immerse the clean nickel foam sheet into 10mL of water and ethanol mixed solution containing manganese dichloride, cobalt chloride, citric acid, thiourea (molar ratio 1:2:2:1) (V 水 / V 醇 =1:3), take it out to dry at 75°C, and repeat three times;

[0033] (2) Calcinate the nickel foam sheet obtained in step 1 at 800°C for 6h under the protection of Ar gas at 50mL / min, and then at 200°C, O 2 Heating under the atmosphere for 1 h, cooling to room temperature to obtain a three-dimensional electrode of nitrogen-doped carbon / manganese-cobalt oxide supported on nickel foam.

[0034] The macroscopic comparison of ...

Embodiment 2

[0041] A new three-dimensional anode material for hydrogen production by electrolysis of water, including nitrogen-doped carbon / transition metal nickel-iron oxide supported by nickel foam and its three-dimensional anode sheet for hydrogen production by electrolysis of water, using a liquid-solid synthesis method In situ preparation, the specific steps are:

[0042] (1) Dip the clean foamed nickel sheet into 10mL of water and ethanol mixed solution (V 水 / V 醇 =1:1), take it out to dry at 75°C, and repeat three times;

[0043] (2) Calcinate the foamed nickel sheet obtained in step 1 at 700°C for 1 hour under the protection of Ar gas at 10mL / min, and then at 250°C, O 2 Heating under the atmosphere for 1.2h, cooling to room temperature to obtain a three-dimensional electrode of nitrogen-doped carbon / nickel-iron oxide supported on nickel foam.

Embodiment 3

[0045]A new three-dimensional anode material for hydrogen production by electrolysis of water, including nitrogen-doped carbon / transition metal cobalt-copper oxide supported on nickel foam and its three-dimensional anode sheet for hydrogen production by electrolysis of water, using a liquid-solid synthesis method In situ preparation, the specific steps are:

[0046] (1) Immerse the clean nickel foam sheet into 10mL of water and ethanol mixed solution (V 水 / V 醇 =1:9), take it out to dry at 75°C, and repeat three times;

[0047] (2) Calcinate the foamed nickel sheet obtained in step 1 at 600°C for 5h under the protection of 20mL / min Ar gas, and then at 220°C, O 2 Heating under the atmosphere for 1.5h, cooling to room temperature and then obtaining a three-dimensional electrode of nitrogen-doped carbon / cobalt-copper oxide supported on nickel foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com