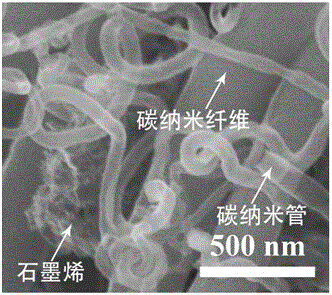

Graphene/carbon nano tube/carbon nanofiber electrocatalyst and preparation method thereof

A carbon nanofiber, carbon nanotube technology, applied in the field of carbon nanofiber-based electrocatalyst and its preparation, can solve the problems of lack of active sites, large contact resistance, non-interconnection of fibers, etc., to improve the reduction performance and the degree of graphitization The effect of increasing, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The graphene / carbon nanotube / carbon nanofiber electrocatalyst of this embodiment is made according to the following method:

[0043] (1) Preparation of spinning solution: Cobalt nitrate (Co(NO 3 ) 2 ), PAN (molecular weight 30000) and DMF were mixed and stirred uniformly at a mass ratio of 0.15:1:9 to obtain a homogeneous spinning solution;

[0044] (2) Electrospinning: The homogeneous spinning solution obtained in step (1) was electrospun to collect Co(NO 3 ) 2 / PAN fibril felt; the process parameters of the electrospinning are: the metal needle with an internal diameter of 0.8mm is used as the nozzle, the spinning voltage is 15kV, the vertical distance from the needle point to the receiving screen is 15cm, and the feed rate is 15 μL / min , the spinning temperature is 25°C, the relative humidity of the air is 30RH%, and the flat aluminum foil is collected;

[0045] (3) Pre-oxidation: Co(NO 3 ) 2 / PAN fibril mat is placed in a pre-oxidation furnace, and in an air a...

Embodiment 2

[0056] The graphene / carbon nanotube / carbon nanofiber electrocatalyst of this embodiment is made according to the following method:

[0057] (1) Preparation of spinning solution: ferric chloride (FeCl 3 ), PVP (molecular weight 1,500,000) and DMSO were mixed and stirred uniformly at a mass ratio of 0.1:1:9 to obtain a homogeneous spinning solution;

[0058] (2) Electrospinning: Electrospinning the homogeneous spinning solution obtained in step (1) to collect FeCl 3 / PVP fibril felt; the process parameters of the electrospinning are: the metal needle with an inner diameter of 0.8mm is used as the nozzle, the spinning voltage is 12kV, the vertical distance from the needle tip to the receiving screen is 25cm, and the feed rate is 20 μL / min , the spinning temperature is 30°C, the relative humidity of the air is 15RH%, and the flat aluminum foil is collected;

[0059] (3) Pre-oxidation: FeCl obtained in step (2) 3 / PVP fibril mats are placed in a pre-oxidation furnace, and in an ...

Embodiment 3

[0064] The graphene / carbon nanotube / carbon nanofiber electrocatalyst of this embodiment is made according to the following method:

[0065] (1) Preparation of spinning solution: Nickel acetylacetonate (Ni(C 5 h 7 o 2 ) 2 ), phenolic resin (molecular weight: 120000) and DMF were mixed and stirred uniformly at a mass ratio of 0.25:1:9 to obtain a homogeneous spinning solution;

[0066] (2) Electrospinning: The homogeneous spinning solution obtained in step (1) was electrospun to collect Ni(C 5 h 7 o 2 ) 2 / phenolic resin fibril mat; the process parameters of the electrospinning are: the metal needle with an internal diameter of 0.8mm is used as the nozzle, the spinning voltage is 20kV, the vertical distance from the needle point to the receiving screen is 10cm, and the feed rate is 10 μL / min, the spinning temperature is 10°C, the relative air humidity is 40RH%, and the flat aluminum foil is collected;

[0067] (3) Pre-oxidation: Ni(C) obtained in step (2) 5 h 7 o 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com