A treatment method for landfill leachate

A technology of landfill leachate and treatment method, which is applied in the field of landfill leachate treatment in sewage treatment, and can solve the problems that the concentrated solution of pollutants cannot be treated and the heat preservation effect of the reactor is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

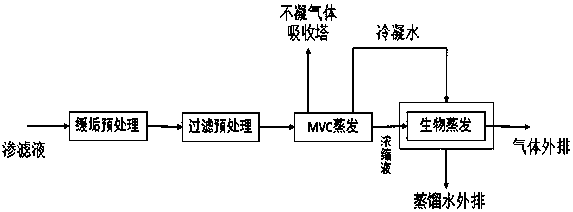

[0029] Embodiment 1: as figure 1 Shown, the processing method technological process of this landfill leachate comprises the following steps:

[0030] (1) Preparation of biofilm sponge used as bio-evaporative expansion agent and bio-carrier

[0031] ① Crush the polyurethane sponge to a diameter of 1 mm;

[0032] ② Prepare synthetic wastewater with COD=500 mg / L, which contains glucose 0.44 g / L, yeast extract 0.06 g / L, NH 4 Cl 0.09 g / L, KH 2 PO 4 0.01 g / L, K 2 HPO 4 0.01 g / L, NaH 2 PO 4 0.067 g / L, Na 2 HPO 4 0.338 g / L, CaCl 2 2H 2 O 6.8 μg / L, MgCl 2 ·6H 2 O 12.1μg / L, FeCl 3 ·6H 2 O 0.551μg / L, MnCl 2 4H 2 O0.22μg / L, ZnSO 4 ·7H 2 O 0.0734μg / L, CuCl 2 2H 2 O 0.096μg / L, CoCl 2 ·6H 2 O 0.136 μg / L, Na 2 MoO 4 2H 2 O 0.0205μg / L;

[0033] ③Put the pulverized polyurethane sponge into the reactor, and pump the synthetic wastewater from the bottom of the reactor to ensure a hydraulic retention time of 8 h, then inoculate the activated sludge with MLSS of 2800 mg / L...

Embodiment 2

[0040] Embodiment 2: the processing method technological process of this landfill leachate comprises the following steps:

[0041] (1) Preparation of biofilm sponge used as bio-evaporative expansion agent and bio-carrier

[0042] ① Crush the polyurethane sponge to a diameter of 3 mm;

[0043] ② Prepare synthetic wastewater with COD=600 mg / L, which contains glucose 0.53 g / L, yeast extract 0.07 g / L, NH 4 Cl 0.11g / L, KH 2 PO 4 0.01 g / L, K 2 HPO 4 0.01g / L, NaH 2 PO 4 0.080g / L, Na 2 HPO 4 0.406g / L, CaCl 2 2H 2 O 8.1 μg / L, MgCl 2 ·6H 2 O 14.5μg / L, FeCl 3 ·6H 2 O0.660μg / L, MnCl 2 4H 2 O0.27μg / L, ZnSO 4 ·7H 2 O 0.0880μg / L, CuCl 2 2H 2 O 0.116μg / L, CoCl 2 ·6H 2 O 0.164 μg / L, Na 2 MoO 4 2H 2 O 0.0248μg / L;

[0044] ③Put the pulverized polyurethane sponge into the reactor, and pump the synthetic wastewater from the bottom of the reactor to ensure a hydraulic retention time of 9 h, then inoculate the activated sludge with MLSS of 3000 mg / L into the reactor, so tha...

Embodiment 3

[0051] Embodiment 3: the processing method technological process of this landfill leachate comprises the following steps:

[0052] (1) Preparation of biofilm sponge used as biological evaporation expansion agent and biological carrier:

[0053] ① Crush the polyurethane sponge to a diameter of 5 mm;

[0054] Prepare synthetic wastewater with COD=700 mg / L, its composition is glucose (0.62 g / L), yeast extract (0.08g / L), NH 4 Cl (0.12 g / L), KH 2 PO 4 (0.02 g / L), K 2 HPO 4 (0.02 g / L), NaH 2 PO 4 (0.094 g / L), Na 2 HPO 4 (0.474 g / L), CaCl 2 2H 2 O (9.5μg / L), MgCl 2 ·6H 2 O (16.9μg / L), FeCl 3 ·6H 2 O (0.771μg / L), MnCl 2 4H 2 O (0.31μg / L), ZnSO 4 ·7H 2 O (0.1030μg / L), CuCl 2 2H 2 O(0.135μg / L), CoCl 2 ·6H 2 O (0.191 μg / L), Na 2 MoO 4 2H 2 O (0.0290μg / L);

[0055] ③Put the pulverized polyurethane sponge into the reactor, and pump the synthetic wastewater from the bottom of the reactor to ensure that the hydraulic retention time is 10 h, and then inoculate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com