Preparation method and application of hollow melamine formaldehyde resin microspheres

A melamine and formaldehyde resin technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of poor mechanical strength and leveling ability, increase in resin viscosity, decrease in polishing resistance, etc., to achieve high dispersion and reduce energy loss. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

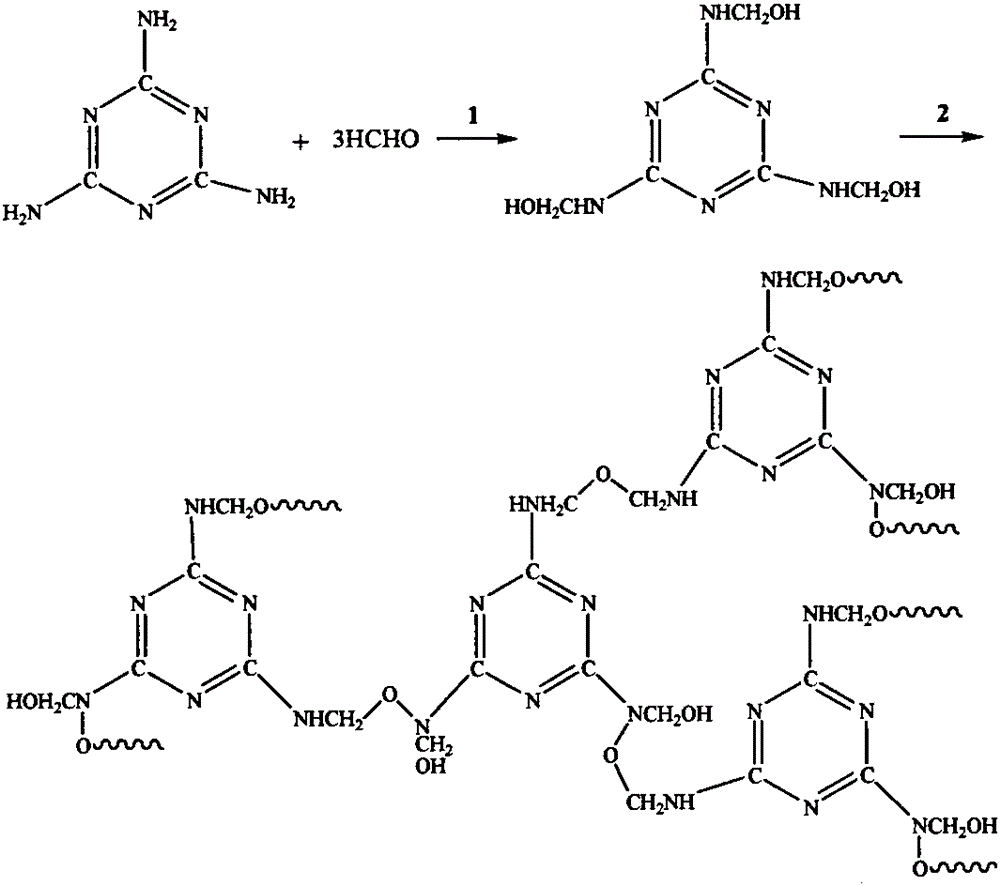

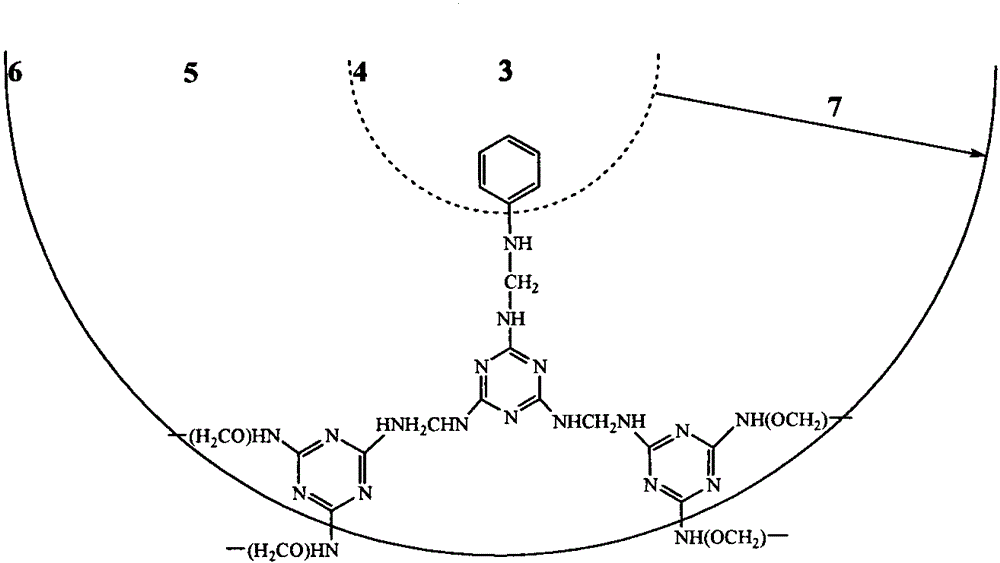

Method used

Image

Examples

Embodiment 1

[0038] (1) Synthesis of prepolymer: get 9.5g formaldehyde (37%, mass fraction), 3.3g melamine and 14.0g deionized water in conical flask, adjust pH with sodium bicarbonate solution (10%, mass fraction) to 11.5, and stirred at 65°C for about 15 minutes, the solution became clear, and a melamine formaldehyde prepolymer was obtained.

[0039] (2) Construction of microbubble system: 95g polyvinyl alcohol aqueous solution (PVA1795, 4%, mass fraction) and 1.1g aniline are added in the reaction vessel, feed air under 65 ℃ to make the pressure reach 0.8MPa, and maintain 10 minutes, Then the valve is opened, the pressure is reduced to normal pressure, a large number of microbubbles are generated in the solution, and a microbubble system is constructed.

[0040] (3) Preparation of hollow microspheres: Add 0.33 g of glycine to the microbubble solution in step 2, add the melamine formaldehyde prepolymer dropwise into the microbubble solution with a dropper, stir and react at 65°C for 15 m...

Embodiment 2

[0042] (1) Synthesis of prepolymer: get 8.2g formaldehyde (37%, mass fraction), 3.8g melamine and 12.5g deionized water in conical flask, adjust pH to 10.5, and stirred at 60°C for about 18 minutes, the solution became clear, and a melamine formaldehyde prepolymer was obtained.

[0043] (2) Construction of the microbubble system: 86g polyethylene glycol aqueous solution (averageMn4000, 4%, mass fraction) and 1.5g toluidine are added in the reaction vessel, feed carbon dioxide gas under 60 ℃ to make the pressure reach 0.7MPa, and keep After 15 minutes, the valve is opened, the pressure is reduced to 0.1MPa, a large number of microbubbles are generated in the solution, and a microbubble system is constructed.

[0044] (3) Preparation of hollow microspheres: add 0.5 g of alanine to the microbubble solution in step 2, add the melamine-formaldehyde prepolymer dropwise into the microbubble solution with a dropper, and stir and react at 60° C. for 20 minutes. Sodium carbonate soluti...

Embodiment 3

[0046] (1) Synthesis of prepolymer: get 8.3g formaldehyde (37%, mass fraction), 3.5g melamine and 10.0g deionized water in conical flask, adjust pH to 11.0 with ammoniacal liquor (10%, mass fraction), And stirred and reacted at 65°C for about 16 minutes, the solution became clear, and a melamine formaldehyde prepolymer was obtained.

[0047] (2) Construction of the microbubble system: Add 92g of sodium polyacrylate aqueous solution and 1.3g of chloroaniline into the reaction vessel, feed sulfur hexafluoride gas at 70°C to make the pressure reach 0.7MPa, and keep it for 30 minutes, then open the valve, When the pressure is reduced to 0.3MPa, a large number of microbubbles are generated in the solution, and a microbubble system is constructed.

[0048] (3) Preparation of hollow microspheres: add 0.28 g of valine to the microbubble solution in step 2, add the melamine-formaldehyde prepolymer dropwise into the microbubble solution with a dropper, and stir and react for 10 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com