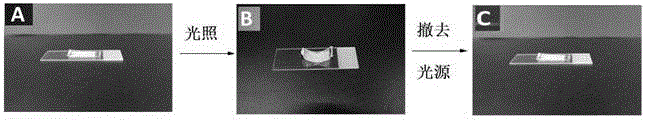

Photothermally-induced shape memory composite and preparation method thereof

A technology for composite materials and photothermal conversion materials, applied in the field of photothermal shape memory composite materials and their preparation, can solve the problems of limited application fields, poor mechanical properties, limited applications, etc., and achieves wide applicability, good practicability, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of a photothermally induced shape memory composite material, comprising the following steps:

[0053] (1) Preparation of surface functionalized gold nanorods:

[0054] a. After adding 0.2 mL of chloroauric acid solution (13 mM) to 9 mL (118 mM) of cetyl trimethyl ammonium bromide, 90 μL of silver nitrate solution (25 mM) was added thereto, and then 120 μL of silver nitrate solution was added thereto. The catechol and 5 μl of sodium borohydride solution were reacted at room temperature for 8 hours to obtain a 5 mM solution of gold nanorods.

[0055] b. Amination of gold nanorods:

[0056] Take 2 mL of the 5 mM gold nanorod solution in the above step (a), add 4 mL and 100 mM of mercaptoethylamine, stir at room temperature, and then purify by centrifugation, and then disperse into 2 mL of water to obtain 5 mM mercaptoethylamine-functionalized gold nanoparticles. Rod, that is, light-to-heat conversion material;

[0057] (2) Intermixing of gold nanoro...

Embodiment 2

[0063] A preparation method of a photothermally induced shape memory composite material, comprising the following steps:

[0064] (1) Preparation of polyaniline nanofibers:

[0065] 4 mmol of aniline was dissolved in 4 mL of methylene chloride, 4 mL of 1 mol / L ferric chloride solution was added thereto, polyaniline nanofibers were obtained by interfacial polymerization for 10 min, and the product was purified with deionized water to obtain a photothermal conversion material;

[0066] (2) Mixing of polyaniline nanofibers and temperature-sensitive materials:

[0067] Take N-isopropylacrylamide (1.0g), acrylic acid (0.5mL), and methylenebisacrylamide (0.1g) as the prepolymer of the temperature-sensitive material, and add 3mL, 0.1mol / L polyaniline nanofibers to it , adding 8 mL of water for ultrasonic dispersion to obtain a mixed dispersion of the photothermal conversion material and the temperature-sensitive material;

[0068] (3) Chromium layer and gold layer with thickness of...

Embodiment 3

[0072] A preparation method of a photothermally induced shape memory composite material, comprising the following steps:

[0073] (1) Preparation of surface functionalized reduced graphene oxide (rGO):

[0074] 4 mmol of aniline was dissolved in 4 mL of dichloromethane, 4 mL of 1 mol / L ferric chloride solution was added thereto, polyaniline nanofibers were obtained by interfacial polymerization for 10 min, and the product was purified with deionized water, that is, a photothermal conversion material;

[0075] 150 μL of the elastin-like polypeptide derivative V at a concentration of 2 mg / mL 50 GB solution was mixed with 450 μL of reduced graphene oxide solution (rGO) in a mass ratio of 6:1, and mixed at 4 °C for 18 h to obtain V 50GB-functionalized rGO, purified with deionized water, i.e. functionalized photothermal conversion material;

[0076] (2) Mixed copolymerization of functionalized rGO and thermosensitive materials:

[0077] Take 0.2 mL of the above functionalized rG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com