Tungsten disulfide/molybdenum disulfide/montmorillonite compound and preparation method thereof

A technology of tungsten disulfide and molybdenum disulfide, which is applied in chemical instruments and methods, chemical/physical processes, lubricating compositions, etc., can solve problems such as difficulty in preparing tungsten disulfide, etc., and achieve low production cost and shorten the synthesis time. time, the effect of reducing the cost of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

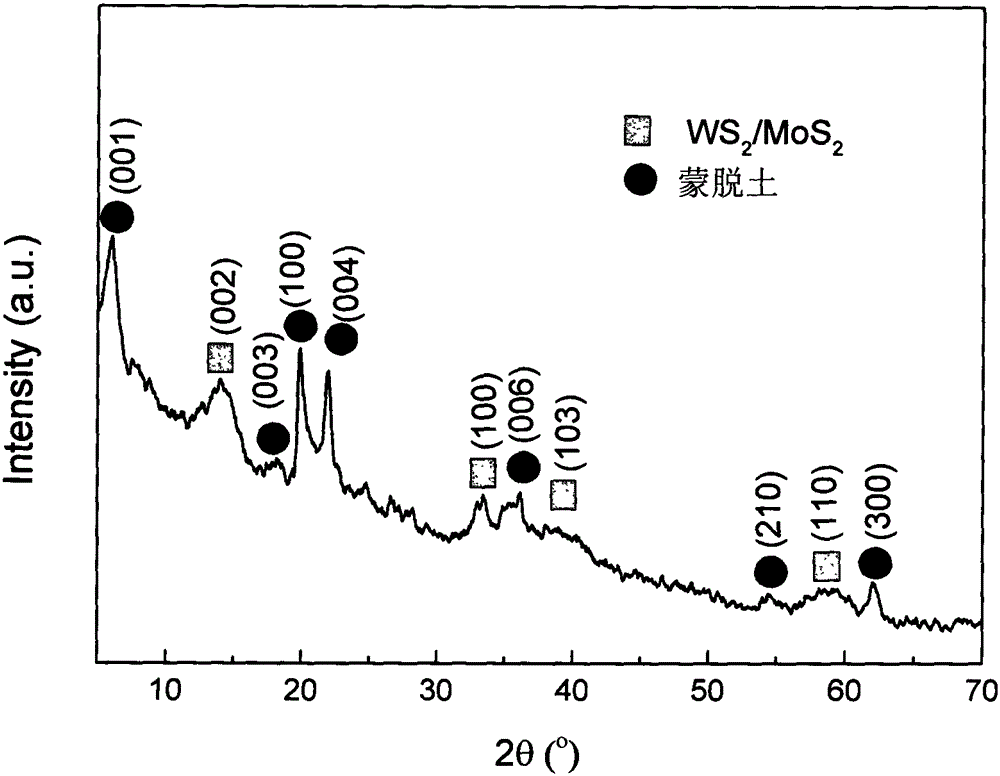

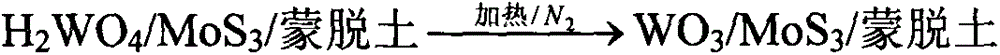

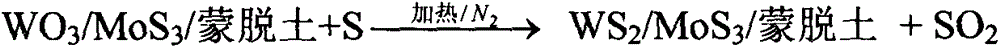

[0035] Dissolve 1 part of sodium molybdate, 1.5 parts of sodium tungstate and 3 parts of thioacetamide in 120 parts of water, add 2 parts of montmorillonite, stir to 82°C while heating, and add concentrated hydrochloric acid to adjust the pH to 0.5. When the co-precipitation reaction starts, after the reaction is completed, the precursor of the composite is obtained by filtering, washing and drying. The precursor and 10 parts of elemental sulfur are uniformly mixed, and then the mixture is put into N 2 In a tube furnace, heated to 300°C and held for 60 minutes, then raised the temperature to 600°C and held for 30 minutes, and finally cooled to room temperature to take out the sample to obtain a tungsten disulfide / molybdenum disulfide / montmorillonite composite. (Such as figure 1 Shown in the map).

Embodiment 2

[0037] Dissolve 1 part of ammonium molybdate, 1.5 parts of ammonium tungstate and 3 parts of thioacetamide in 120 parts of water, add 0.5 part of montmorillonite, stir while heating to 82°C, add concentrated hydrochloric acid to adjust the pH to 0.5. When the co-precipitation reaction started, after the reaction, the precursor of the composite was obtained by filtering, washing and drying. The precursor was mixed with 10 parts of elemental sulfur uniformly, and then the mixture was heated to 300 in a tube furnace with Ar gas. ℃ and hold for 60 minutes, then raise the temperature to 600 ℃ and hold for 30 minutes, and finally cool to room temperature and take out the sample to obtain a tungsten disulfide / molybdenum disulfide / montmorillonite composite (approximately figure 1 Shown in the map).

Embodiment 3

[0039] Dissolve 1 part of potassium molybdate, 1.5 parts of potassium tungstate and 3 parts of thioacetamide in 120 parts of water, add 10 parts of montmorillonite, stir to 82°C while heating, and add concentrated hydrochloric acid to adjust the pH to 0.5. When the co-precipitation reaction starts, after the reaction is completed, the precursor of the composite is obtained by filtering, washing and drying. The precursor and 10 parts of elemental sulfur are uniformly mixed, and then the mixture is put into N 2 In a tube furnace, heated to 300°C and held for 60 minutes, then increased the temperature to 600°C and held for 30 minutes, and finally cooled to room temperature. The sample was taken out to obtain a tungsten disulfide / molybdenum disulfide / montmorillonite composite (approximately in figure 1 Shown in the map).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com