A solar cell encapsulation film

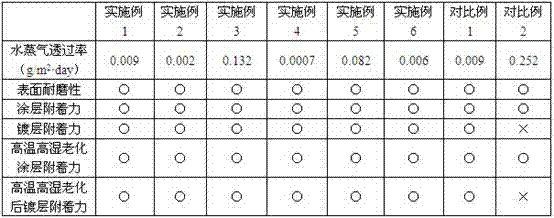

A solar cell and encapsulation film technology, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., to achieve high transparency, improve conversion efficiency, and reduce the effect of battery component failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

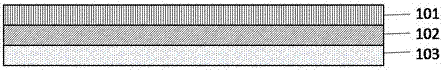

[0040] Preparation steps of the present invention:

[0041] Step 1, carrying out corona treatment on both sides of the transparent support;

[0042] Step 2: prepare a wear-resistant filter coating solution, apply the coating solution on the surface of a transparent support, control the thickness of the coated film through the selection of vehicle speed and anilox roller, and perform UV curing after drying to obtain a wear-resistant filter layer;

[0043] Step 3: Carry out vacuum coating on the other side of the transparent support, and obtain a gas barrier layer by controlling the speed of the vehicle and the film forming process.

Embodiment 1

[0046] ETFE film with a thickness of 50 μm is selected, after surface cleaning and pretreatment, corona treatment is carried out;

[0047] Prepare a wear-resistant coating solution, use an anilox roller to coat a wear-resistant filter coating on the surface of the ETFE film, the thickness of the coating is controlled to 3 μm, and after drying at 80°C, use ultraviolet light to cure.

[0048] After curing, PECVD is used to deposit a silicon oxide film with a thickness of 300 nm on the surface of the uncoated ETFE film to obtain the required solar cell front-side packaging film material.

[0049] The coating liquid composition as shown in embodiment 1 is:

[0050] A wear-resistant filter coating solution is composed of ITO nanoparticles with a diameter of 10 nanometers and a transparent wear-resistant coating solution, wherein the mass percentage of ITO in the wear-resistant filter coating solution is 10%;

[0051] The transparent wear-resistant coating solution is an ultraviole...

Embodiment 2

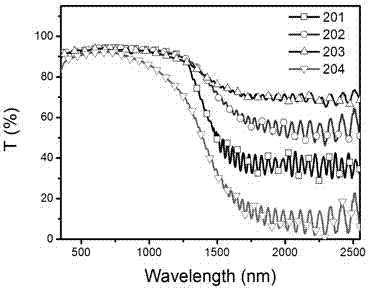

[0054] In Example 1, the mass percentage of ITO nanoparticles in the wear-resistant filter coating solution is 5%, and the thickness of the deposited silicon oxide film is 400nm. Except for this, the same operation as Example 1 is performed. The optical transmittance test and characterization of the obtained solar cell encapsulation film were carried out, and the results were as follows: figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com