Diterpenoid compounds, and preparation method and application thereof

A technology of compounds and diterpenoids, applied in the field of diterpenoids and their preparation, can solve the problem of low pharmacological activity, achieve high purity, easy industrial production, and good anticancer activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

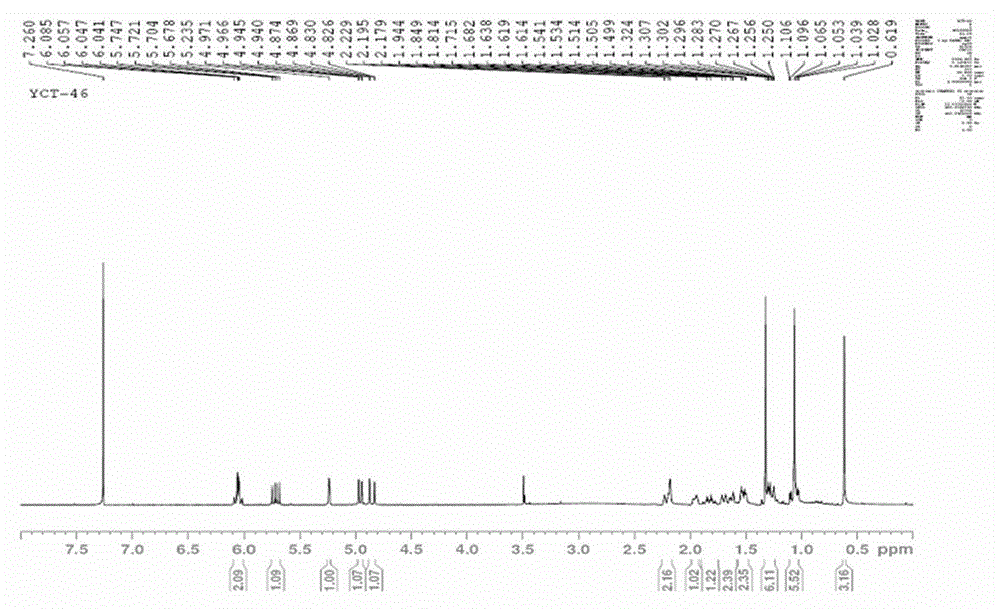

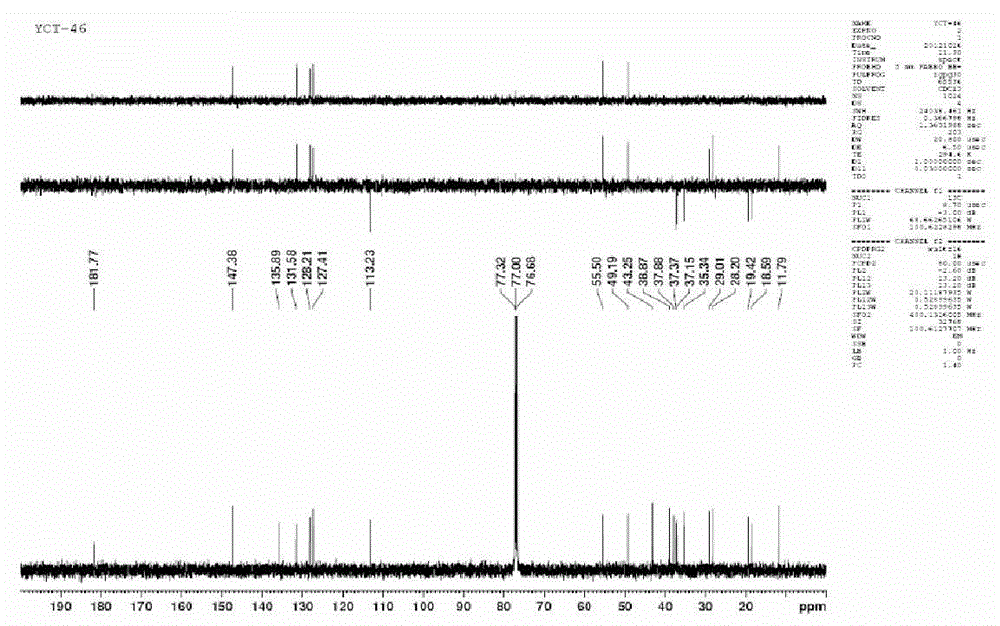

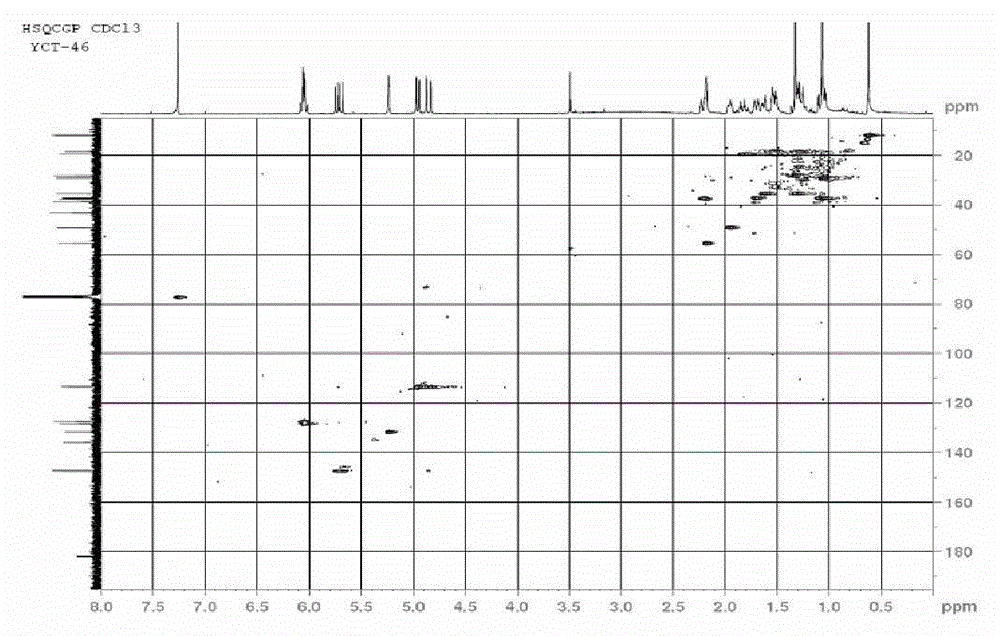

Image

Examples

preparation example Construction

[0034] The preparation method of the diterpenoid compound of the present invention is to use the root of Angelica sinensis as a raw material, and obtain it through extract extraction, organic solvent extraction, silica gel column chromatography, and high-pressure liquid chromatography, specifically:

[0035] A, extraction of extract: dry and pulverize the roots of Angelica sinensis to obtain 0.05 ~ 0.15cm particle size, add 80 ~ 95% ethanol solution with a volume percentage concentration of 4 ~ 8 times of root weight ratio of Angelica sinensis in Reflux extraction at 65~74°C for 3~5 times, each time for 1~3h, combine the extracts, filter the extracts, concentrate the extracts under reduced pressure until the specific gravity is 1.1~1.3 to obtain the extract a;

[0036] B, organic solvent extraction: add the water of 2~4 times of weight ratio in extract a, carry out extraction with sherwood oil, ethyl acetate and n-butanol solvent of equal volume to water successively, every kin...

Embodiment 1

[0049] The preparation of embodiment 1 compound

[0050] Source of material: Heiguo soil angelica was collected in Kunming, Yunnan, and was identified as Aralia du Metorum Hand.-Mazz, the specimen is preserved in the Herbarium of the School of Medicine for Nationalities, Yunnan University for Nationalities.

[0051] Take the following steps:

[0052] (1) Dry and crush 10Kg of Angelica sinensis roots into particles with a particle size of 0.1cm to obtain Angelica sinensis powder. Reflux the Angelica sinensis powder with 60Kg of 80% ethanol at a temperature of 65°C each time Extract 4 times, 2 hours each time, combine the ethanol extracts, and set aside;

[0053] (2) Filter the ethanol extract prepared in step (1) through 80-120 micron filter paper and concentrate under reduced pressure with a rotary evaporator at a temperature of 50°C until the specific gravity is 1.2 to obtain 1380g of extract for later use;

[0054] (3) Suspend 1380g of the extract in (2) in 4500ml of wat...

Embodiment 2

[0056] The preparation of embodiment 2 compound

[0057] Take the following steps:

[0058] (1) Dry and crush 10Kg of Angelica sinensis roots into particles with a particle size of 0.1cm to obtain Angelica sinensis powder. Reflux the Angelica sinensis powder with 60Kg of 84% ethanol at a temperature of 67°C each time Extract 3 times, 2.5 hours each time, combine the ethanol extracts, and set aside;

[0059] (2) Filter the ethanol extract prepared in step (1) through 80-120 micron filter paper and concentrate under reduced pressure with a rotary evaporator at a temperature of 50°C until the specific gravity is 1.2 to obtain 1340g of extract for later use;

[0060] (3) Suspend 1340g of the extract in (2) in 4000ml of water, sequentially extract with 4000ml of petroleum ether, 4000ml of ethyl acetate and 4000ml of n-butanol, extract 4 times with each solvent, and then evaporate it with a rotary evaporator Solvent, respectively petroleum ether, ethyl acetate and n-butanol extrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com