Graphene-containing fluororubber nanocomposite with low gas permeability and preparation method

A nano-composite material and graphene technology, applied in the field of rubber materials, can solve the problems of difficult to avoid solvent residues, insufficient process stability, poor graphene dispersibility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

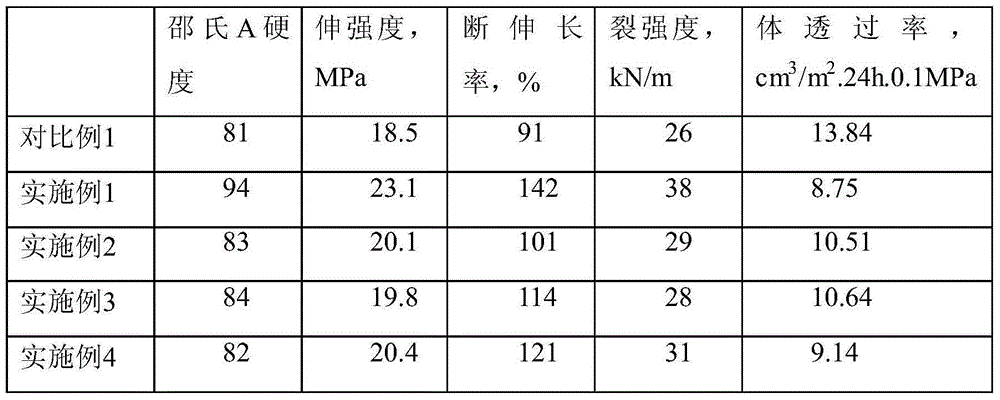

Examples

Embodiment 1

[0032] The low gas permeability graphene / fluororubber nanocomposite material consists of 100 parts by mass of fluororubber, 20 parts of graphene, 0 parts of carbon black, 0 parts of graphite, 3 parts of magnesium oxide, and 1 part of calcium hydroxide. 1 part of calcium oxide, 3.4 parts of vulcanizing agent bisphenol AF, and 0.6 part of BPP.

[0033] Put graphene, carbon black, graphite, and acid absorbing agent into an asymmetric double planetary mixer, and stir at 20r / min for 8h; then immediately add the powder and fluororubber to the internal mixer, and banbury at 60°C for 200min .

[0034] Then, the nanocomposite blend and vulcanizing agent were evenly mixed on a two-roller rubber mixer, and vulcanized on a flat vulcanizer at 175 ° C and a pressure of 10 MPa for 15 minutes to obtain graphene-containing fluororubber nanocomposites. The nano-composite material is subjected to various performance tests according to the corresponding national standards.

Embodiment 2

[0036] The graphene-containing fluorine rubber nanocomposite material consists of 100 parts by mass of fluorine rubber, 0.05 parts of graphene, 8 parts of carbon black, 20 parts of graphite, 2 parts of magnesium oxide, 1 part of calcium hydroxide, and 1 part of calcium oxide 1 part, vulcanizing agent bisphenol AF3.4 part, BPP0.6 part.

[0037] Put graphene, carbon black, graphite, and acid absorbing agent into an asymmetric double planetary mixer, and stir for 4 hours at 60r / min; put the powder into an internal mixer together with fluororubber after 2 hours, and banbury at 100°C 100min.

[0038] Then, the nanocomposite blend and vulcanizing agent were evenly mixed on a two-roller rubber mixer, and vulcanized on a flat vulcanizer at 175°C and a pressure of 10MPa for 15min to obtain graphene-containing fluorine rubber nanocomposites. The nano-composite material is subjected to various performance tests according to the corresponding national standards.

Embodiment 3

[0040] The fluororubber nano-composite material containing graphene consists of 100 parts by mass of fluororubber, 0.1 part of graphene, 25 parts of carbon black, 16 parts of graphite, 4 parts of magnesium oxide, and 1 part of vulcanizing agent 3# vulcanizing agent , 1.2 parts of hydroquinone, and 0.5 parts of BPP.

[0041] Put graphene, carbon black, graphite, and acid absorbing agent into an asymmetric double planetary mixer, and stir at 60r / min for 4h; then immediately add the powder and fluororubber to the internal mixer, and banbury at 110°C for 100min .

[0042] Then, the nanocomposite blend and vulcanizing agent were evenly mixed on a two-roller rubber mixer, and vulcanized on a flat vulcanizer at 160 ° C and a pressure of 10 MPa for 15 minutes to obtain graphene-containing fluororubber nanocomposites. The nano-composite material is subjected to various performance tests according to the corresponding national standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com