Preparation method for flame-retardant heat-resistant antenna radome base material

A radome and base material technology, which is applied in the field of preparation of flame-retardant and heat-resistant radome base materials, can solve the problems of heavy metal materials, poor thermal shock resistance, and difficult molding and processing, and achieve good compatibility and adhesion Good connection performance and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 A method for preparing a flame-retardant and heat-resistant radome base material, comprising the following steps:

[0025] (1) Disperse 1000g of nano-silica foam in deionized water, then add 100g of dodecylbenzenesulfonic acid, 400g of bismuth nitrate pentahydrate and 600g of methyltrichlorosilane; then hydrothermally react at 120°C for 5 hours; Then filter the reaction solution, wash the filter cake with deionized water, and obtain a filler whose average particle diameter is 180 nanometers after drying;

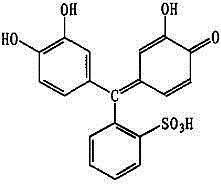

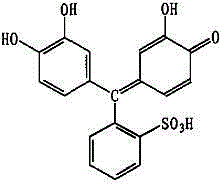

[0026] (2) Mix 8g DOPO and 100g bisphenol A cyanate monomer, stir at 90°C for 20 minutes, then add 25g phenol compound, continue stirring for 10 minutes; then add 9g 1,3,5-triglycidyl-S-triazinetrione , 28g bisphenol A epoxy resin, continue to stir for 40 minutes; Add 15g diaminodiphenyl ether, stir for 30 minutes at 120 ℃; Obtain resin prepolymer;

[0027] (3) Mix 100g of resin prepolymer with 14g of maleic anhydride and stir at 120°C for 30 minutes; th...

Embodiment 2

[0030] Embodiment 2 A method for preparing a flame-retardant and heat-resistant radome substrate, comprising the following steps:

[0031] (1) Disperse 1000g of nano-silica foam in deionized water, then add 100g of dodecylbenzenesulfonic acid, 400g of bismuth nitrate pentahydrate and 600g of methyltrichlorosilane; then hydrothermally react at 120°C for 5 hours Then filter the reaction solution, wash the filter cake with deionized water, and obtain a filler whose average particle diameter is 180 nanometers after drying;

[0032] (2) Mix 8g DOPO and 100g bisphenol A cyanate monomer, stir at 90°C for 20 minutes, then add 20g phenol compound, continue stirring for 10 minutes; then add 10g 1,3,5-triglycidyl-S-triazinetrione , 25g bisphenol A epoxy resin, continue to stir for 40 minutes; add 10g diaminodiphenyl ether, stir 30 minutes at 120 ℃; Obtain resin prepolymer;

[0033] (3) Mix 100g of resin prepolymer with 12g of maleic anhydride and stir at 120°C for 30 minutes; then add 15g...

Embodiment 3

[0034] Embodiment 3 A method for preparing a flame-retardant and heat-resistant radome base material, comprising the following steps:

[0035] (1) Disperse 1000g of nano-silica foam in deionized water, then add 100g of dodecylbenzenesulfonic acid, 400g of bismuth nitrate pentahydrate and 600g of methyltrichlorosilane; then hydrothermally react at 120°C for 5 hours; Then filter the reaction solution, wash the filter cake with deionized water, and obtain a filler whose average particle diameter is 180 nanometers after drying;

[0036] (2) Mix 8g DOPO and 100g bisphenol A cyanate monomer, stir at 90°C for 20 minutes, then add 30g of phenolic compound, continue stirring for 10 minutes; then add 8g of 1,3,5-triglycidyl-S-triazinetrione , 32g bisphenol A epoxy resin, continue to stir for 40 minutes; add 20g diaminodiphenyl ether, stir 30 minutes at 120 ℃; Obtain resin prepolymer;

[0037] (3) Mix 100g of resin prepolymer with 15g of maleic anhydride and stir at 120°C for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com