Method for improving efficiency of producing biogas through anaerobic fermentation by adopting energy grass

An anaerobic fermentation, energy grass technology, applied in fermentation, waste fuel and other directions, can solve the problems of secondary pollution of waste liquid, long cycle, high cost, and achieve the improvement of methane production, specific surface area and accessibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

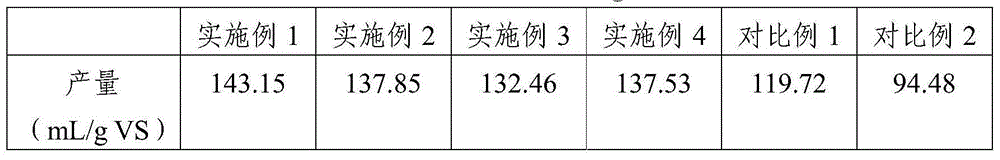

Examples

Embodiment 1

[0029] This embodiment provides a method for improving the efficiency of biogas production by anaerobic fermentation of energy grass, the method comprising the following steps:

[0030] 1) Cut fresh switchgrass stalks to 5-10 cm, freeze-dry in a freeze dryer for 72 hours, crush them, and pass through a 1 mm sieve.

[0031] 2) Mix switchgrass stalks with distilled water at a ratio of 1:30 (w:w) for microwave pretreatment. The microwave pretreatment process is divided into three parts, which are heating stage, heat preservation stage and cooling stage. In the heating stage, the heating rate is 10°C / min. After the microwave treatment temperature rises from room temperature to the target temperature (ie, the final heating temperature), the heating stage is over and the heat preservation stage is entered. In the heat preservation stage, the temperature is always maintained at the set heating final temperature of 180°C, and the duration of the heat preservation stage is the final t...

Embodiment 2

[0033] This embodiment provides a method for improving the efficiency of biogas production by anaerobic fermentation of energy grass, the method comprising the following steps:

[0034] 1) Cut fresh switchgrass stalks to 5-10 cm, freeze-dry in a freeze dryer for 80 hours, crush them, and pass through a 0.5 mm sieve.

[0035] 2) Compared with step 2) of Example 1, the only difference lies in: mixing switchgrass stalks with distilled water at a ratio of 1:30 (w:w) for microwave pretreatment. Microwave pretreatment conditions: heating rate 8°C / min, final heating temperature 90°C, final temperature holding time 15min. After the heat preservation stage is over, the pretreatment system enters the cooling stage, and the temperature is gradually lowered from the final heating temperature to room temperature.

Embodiment 3

[0037] This embodiment provides a method for improving the efficiency of biogas production by anaerobic fermentation of energy grass, the method comprising the following steps:

[0038] 1) Cut fresh switchgrass stalks to 5-10 cm, freeze-dry in a freeze dryer for 72 hours, crush them, and pass through a 1 mm sieve.

[0039] 2) Compared with step 2) of Example 1, the only difference lies in: mixing switchgrass stalks with distilled water at a ratio of 1:25 (w:w) for microwave pretreatment. Microwave pretreatment conditions: heating rate 12°C / min, final heating temperature 150°C, final temperature holding time 0min. After the heat preservation stage is over, the pretreatment system enters the cooling stage, and the temperature is gradually lowered from the final heating temperature to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com