Extraction method of collagen fiber

A technology of collagen fiber and extraction method, which is applied in the field of extraction of collagen fiber and collagen fiber, and can solve the problems of fast degradation rate and too small fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Clean the fresh beef Achilles tendon with purified water, remove the fascia and lean meat with a scalpel blade, cut the beef Achilles tendon, and cut it into 0.5mm thick Achilles tendon slices.

[0084] Take 100 g of Achilles tendon slices and soak them in 5 L of 0.01 mol / L NaOH aqueous solution at 10° C. for 24 hours, wash them with purified water, and adjust the pH value to 7. The Achilles tendon piece was added to 5 L of 0.01 mol / L hydrochloric acid solution and soaked at 10° C. for 48 hours, then washed with purified water, and the pH value was adjusted to 7. Disperse the cleaned tissue in 5L of purified water, adjust the pH to 8.2, add 2g of trypsin to the purified water and treat at 37°C for 2h, then wash with purified water, and adjust the pH to 7.

[0085] The treated Achilles tendon slices were dissolved in 5 L of acetic acid solution with a concentration of 0.3 mol / L, and then pulverized with a tissue grinder. Then add 1 g of pepsin and perform enzymatic hydr...

Embodiment 2

[0090] Clean the fresh beef Achilles tendon with purified water, remove the fascia and lean meat with a scalpel blade, cut the beef Achilles tendon, and cut it into Achilles tendon slices with a thickness of 5 mm.

[0091] Take 100 g of Achilles tendon slices and soak them in 10 L of 0.01 mol / L NaOH aqueous solution at 2° C. for 12 hours, wash with purified water, and adjust the pH value to 7. The Achilles tendon piece was added to 10 L of 0.01 mol / L hydrochloric acid solution and soaked at 2° C. for 12 hours, then washed with purified water, and the pH value was adjusted to 7. Disperse the cleaned tissue in 10 L of purified water, adjust the pH to 8.0, add 3 g of trypsin to the purified water and treat at 35°C for 3 hours, then wash with purified water, and adjust the pH to 7.

[0092] The treated Achilles tendon slices were dissolved in 20 L of acetic acid solution with a concentration of 0.01 mol / L, and then pulverized with a tissue grinder. Add 2 g of pepsin and perform e...

Embodiment 3

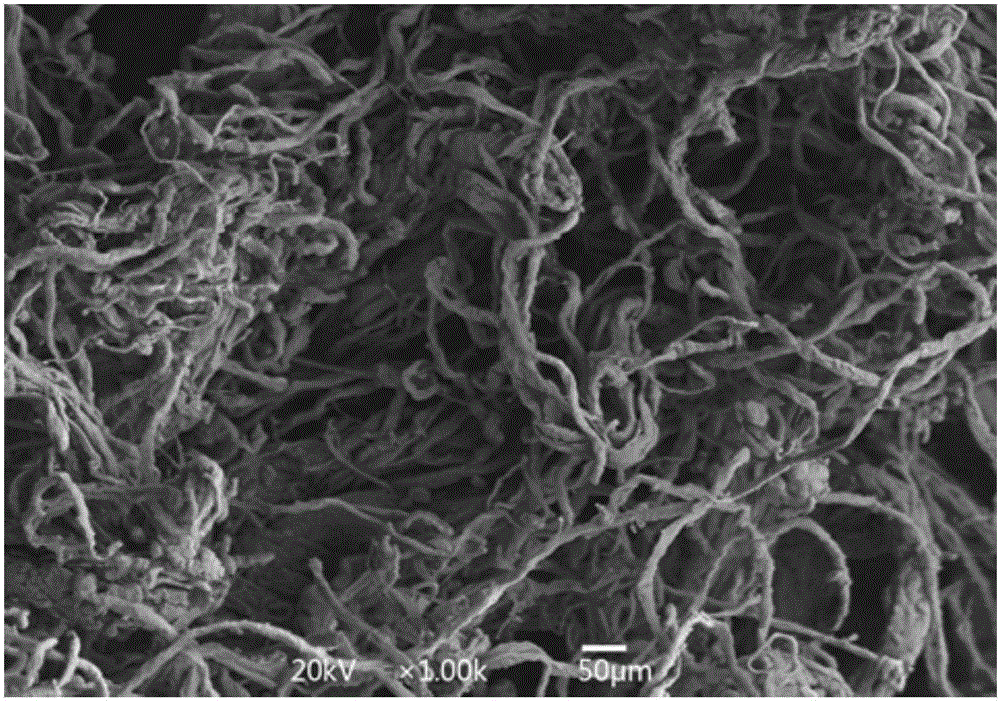

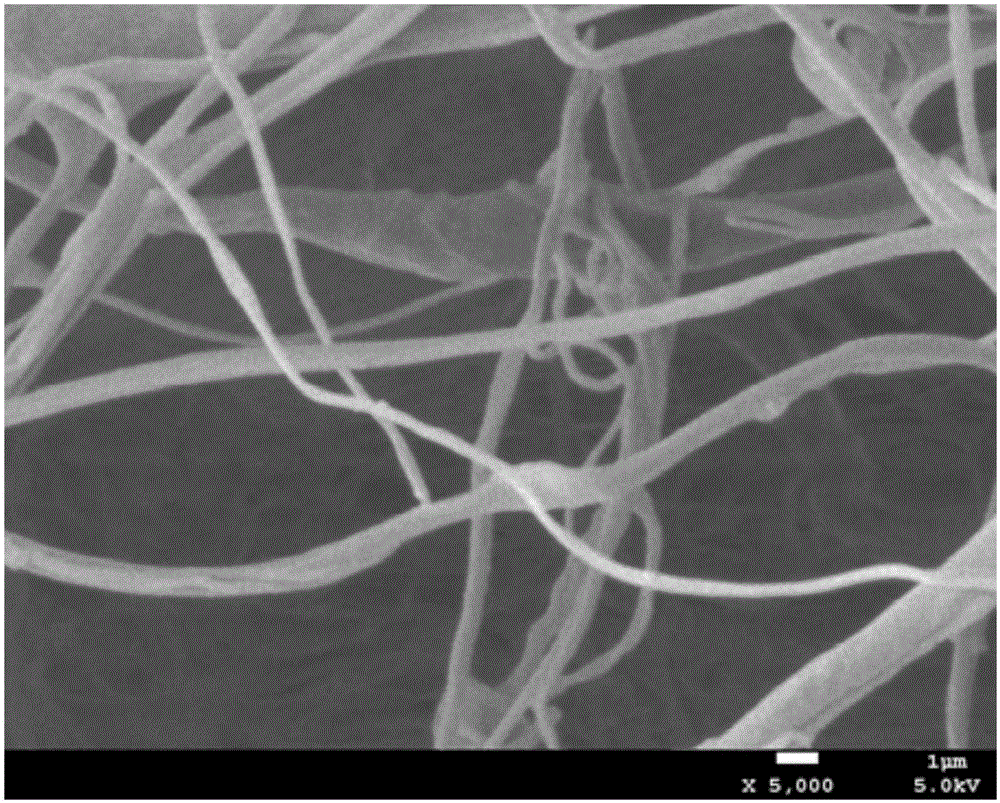

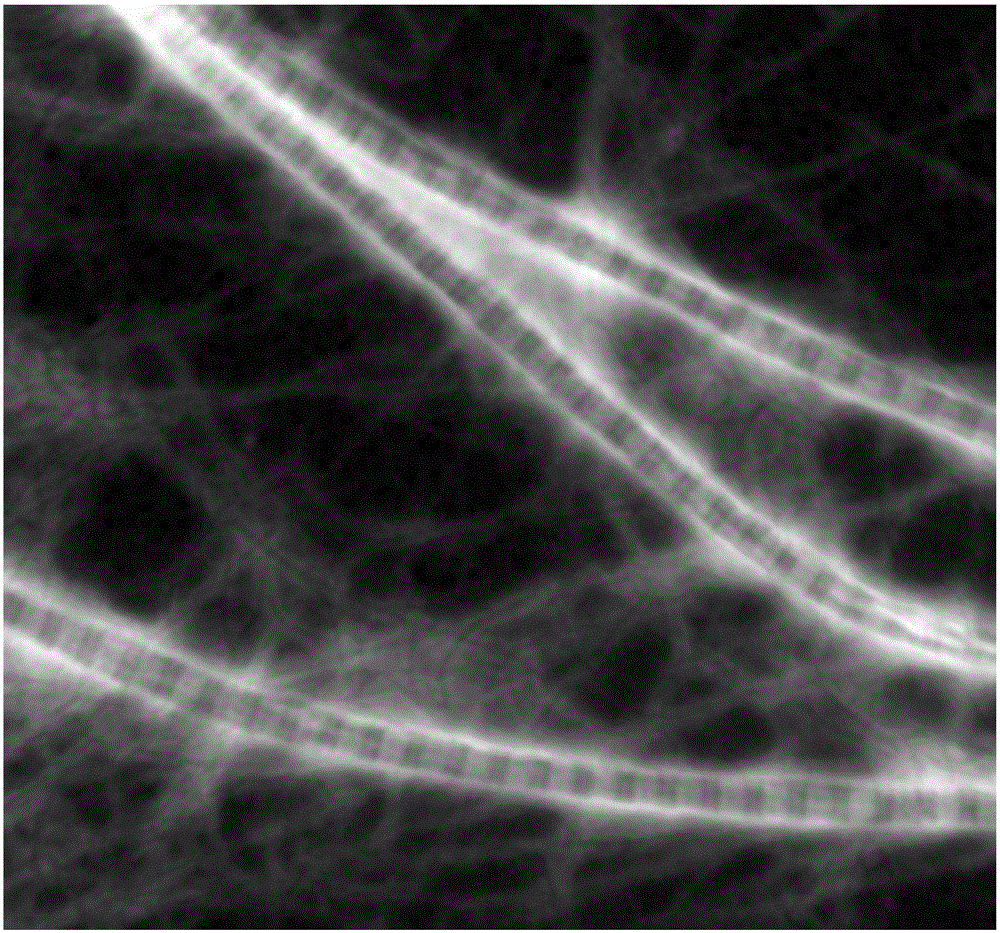

[0103] The collagen fiber samples extracted in Example 1 and Comparative Example 1 were observed with a scanning electron microscope respectively, and the specific data of the fiber diameters can be found in figure 1 , figure 2 . Depend on figure 1 , 2 It can be seen that the average fiber diameter of collagen fiber sample 1# in Example 1 is greater than or equal to 10 μm, while the average fiber diameter of collagen fiber sample 1* in Comparative Example 1 is less than 3 μm. It can be seen that the fiber diameter of the sample in Example 1 is much larger than that in Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com