Ultra-smooth metal film surface preparation method

A metal thin film, ultra-smooth technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of limited application, non-conductivity of mica sheets, etc., and achieve the effect of reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

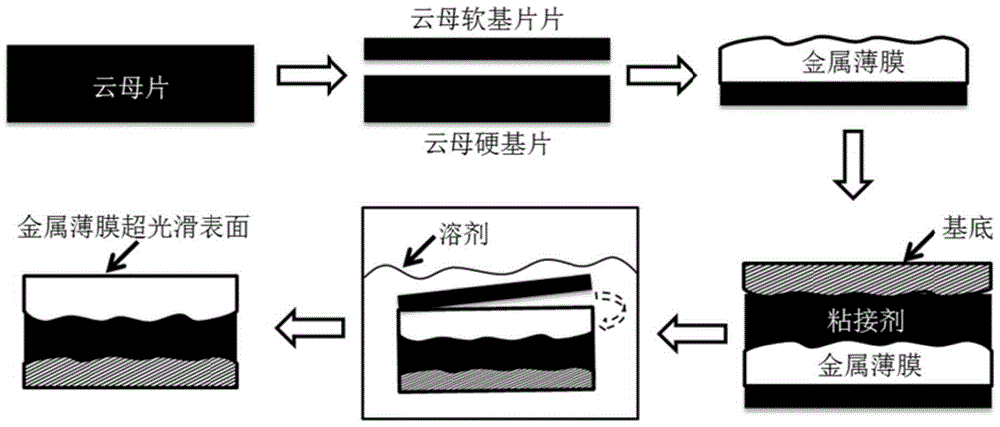

[0030] The preparation method of a kind of ultra-smooth metal thin film surface of the present invention comprises the following steps:

[0031] Step 1, preparation of mica soft substrate

[0032] The preparation process of the mica soft substrate is as follows: in the ultra-clean workbench, the mica sheet with a thickness of about 1 mm is cut into a suitable size substrate with a cutting knife. From the middle line of the thickness, the mica sheet is divided into two substrates A and B with a thickness of about 0.5 mm, wherein the substrate A is used to prepare a mica soft substrate with a thickness of about 2 μm, and the substrate B is used as a mica hard substrate. Place the prepared mica soft substrate. The mica soft substrate is prepared by peeling off layers. The following three steps can be used for specific implementation: 1) Place a disposable medical needle with a diameter of 2 mm in the direction parallel to the thickness of the mica substrate A; 2) Press the medic...

Embodiment 1

[0040] A method for preparing an ultra-smooth metal thin film surface of the present invention comprises the following steps:

[0041] 1. Preparation of mica soft substrate

[0042]Mica is a layered alumina silicate crystal, and the layers are maintained by electrostatic force. The mica can be separated layer by layer by mechanical stripping. When the thickness of the mica sheet is 2 μm (the soft substrate is green), it can not only guarantee the strength requirement, but also have good flexibility. After peeling off the mica soft substrate, adjust the voltage of the DC power supply instrument to 18-20V, the current to 50-200mA, and heat the platinum wire with a diameter of 0.5mm to melt and cut the mica soft substrate. Its advantage is to reduce the deformation produced by the traditional mechanical force cutting method or the pollution of the mica soft substrate by debris in the cutting process. The size of the cut mica soft substrate is 15×15mm. Under the action of elect...

Embodiment 2

[0050] A method for preparing an ultra-smooth metal thin film surface of the present invention comprises the following steps:

[0051] 1. Preparation of mica soft substrate

[0052] The method for preparing the mica soft substrate is as in step 1 in Example 1, and the size of the mica soft substrate is 20×20 mm.

[0053] 2. Deposition of metal thin film on mica soft substrate

[0054] Control the heating current to 2.3-2.7A, make the evaporation temperature at 1080°C-1100°C, and the vacuum degree is 5×10 -3 Au thin films were deposited on mica soft substrates by vapor deposition under Pa. The deposition rate is The deposited film thickness was 50 nm.

[0055] 3. "Sandwich" interlayer preparation

[0056] When preparing the Au metal thin film, the adhesive used in the "sandwich" interlayer is Epoxy377 (EPo, Tek). Epoxy377 consists of two components. Before use, take equal amounts of the components and mix them evenly, then drop 5 μL of adhesive on the curved surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com