A kind of mn3o4/tio2 nanotube composite material and preparation method thereof for supercapacitor

A composite material and nanotube technology, applied in the field of high specific capacitance Mn3O4/TiO2 nanotube composite material and its preparation, can solve the problems of low electrical conductivity, affecting practical application, small specific surface area, etc. Excellent capacitance characteristics, the effect of improving the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

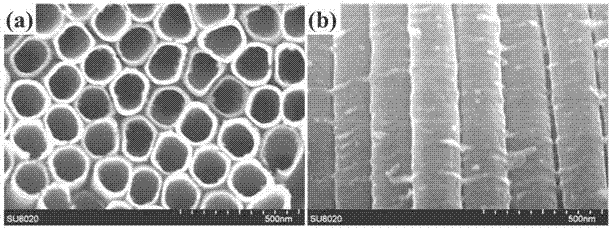

[0026] Step 1, preparation of TiO by electrochemical anodic oxidation process 2 nanotube array

[0027] First add 0.4g NH 4 F dissolved in 5mL H 2 In O, after completely dissolving, add 95mL of ethylene glycol, and ultrasonically mix to obtain 2 O and NH 4The ethylene glycol solution of F; the cleaned high-purity titanium foil is used as an anode, and placed in the above-mentioned 2 O and NH 4 In the electrolytic cell of the ethylene glycol solution of F, the graphite electrode is used as the cathode, and the DC stabilized current power supply is used to oxidize TiO by applying a constant voltage of 40V for 4 hours. 2 nanotube array; the TiO 2 Nanotube arrays were immersed in ethylene glycol solution and ultrasonically cleaned at room temperature for 5 minutes to remove the 2 barrier on the surface of the nanotube array, followed by cleaning the surface with deionized water and blowing dry with nitrogen; the TiO 2 The nanotube array is placed in a muffle furnace and an...

Embodiment 2

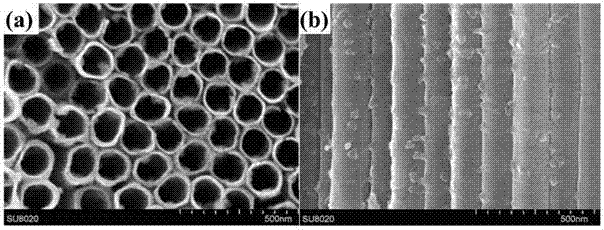

[0032] Step 1, preparation of TiO by electrochemical anodic oxidation process 2 nanotube array

[0033] First add 0.5g NH 4 F dissolved in 6mL H 2 In O, after completely dissolving, add 94mL of ethylene glycol, and ultrasonically mix to obtain 2 O and NH 4 The ethylene glycol solution of F; the cleaned high-purity titanium foil is used as the anode, placed in the 2 O and NH 4 In the electrolytic cell of the ethylene glycol solution of F, the graphite electrode is used as the cathode, and the DC stabilized current power supply is used to oxidize TiO by applying a constant voltage of 50V for 5 hours. 2 nanotube array; the TiO 2 Nanotube arrays were immersed in ethylene glycol solution and ultrasonically cleaned at room temperature for 6 minutes to remove the 2 barrier on the surface of the nanotube array, followed by cleaning the surface with deionized water and blowing dry with nitrogen; the TiO 2 The nanotube array is placed in a muffle furnace and annealed in air at 4...

Embodiment 3

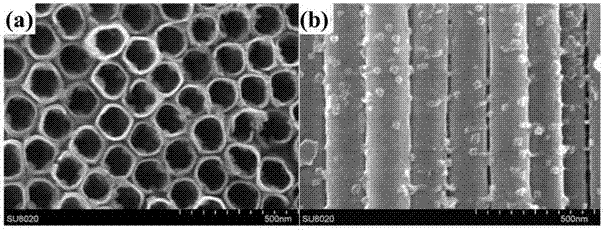

[0038] Step 1, preparation of TiO by electrochemical anodic oxidation process 2 nanotube array

[0039] First add 0.6g NH 4 F dissolved in 8mL H 2 In O, after completely dissolving, add 92mL of ethylene glycol, and ultrasonically mix to obtain 2 O and NH 4 The ethylene glycol solution of F; the cleaned high-purity titanium foil is used as the anode, placed in the 2 O and NH 4 In the electrolytic cell of the ethylene glycol solution of F, the graphite electrode is used as the cathode, and the DC stabilized current power supply is used to obtain TiO by applying a constant voltage of 55V for 6 hours. 2 nanotube array; the TiO 2 Nanotube arrays were immersed in ethylene glycol solution and ultrasonically cleaned for 8 minutes at room temperature to remove the 2 barrier on the surface of the nanotube array, followed by cleaning the surface with deionized water and blowing dry with nitrogen; the TiO 2 The nanotube array is placed in a muffle furnace and annealed in air at 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com