Glass furnace flue gas desulfurization and denitrification system and process

A glass furnace, desulfurization and denitrification technology, which is applied in air quality improvement, dispersed particle separation, chemical instruments and methods, etc. Consumption, increase removal rate, high desulfurization and denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

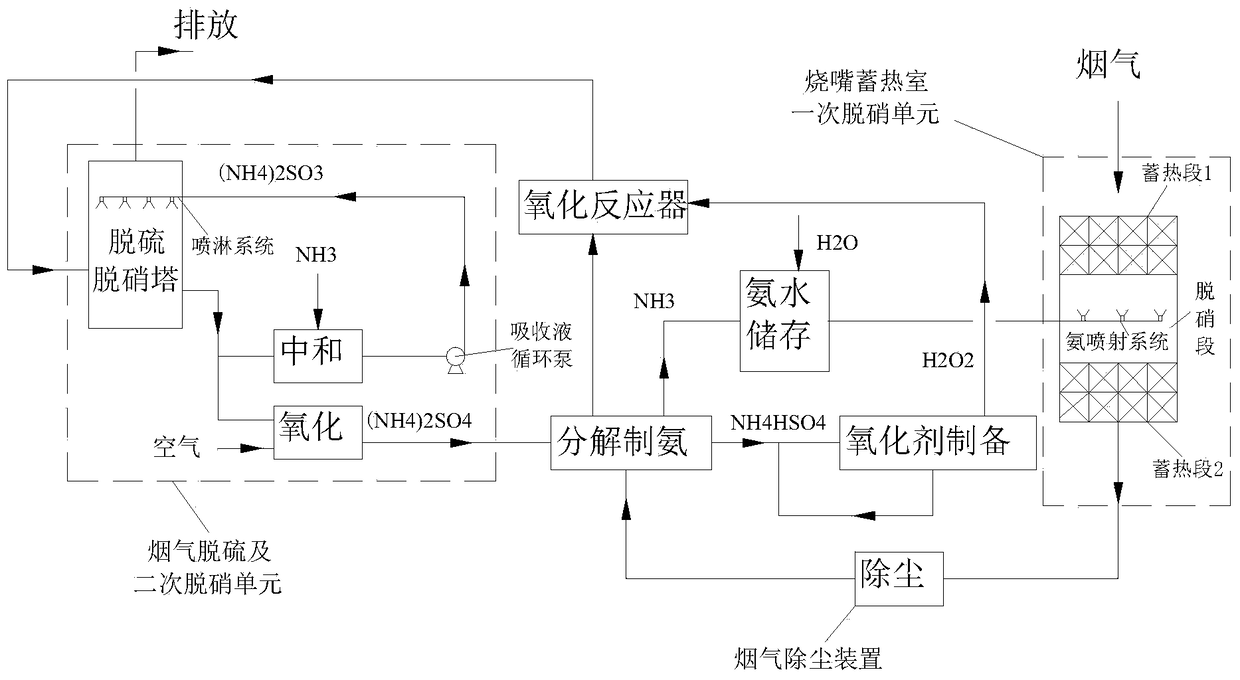

[0056] The invention provides a glass furnace flue gas desulfurization and denitrification system and process. The system includes a glass furnace burner regenerator primary denitrification unit, a flue gas dust removal device, a decomposition ammonia device, an oxidant preparation device and a flue gas desulfurization device. and secondary denitrification unit.

[0057] Among them, the flue gas passes through the primary denitrification unit of the regenerator of the burner of the glass furnace, the flue gas dust removal device, the decomposition ammonia device, and the flue gas desulfurization and secondary denitrification unit.

[0058] The primary denitrification unit of the burner regenerator of the glass furnace includes the first heat storage section, the denitration section and the second heat storage section. The denitration section is set between the first heat storage section and the second heat storage section. Ammonia injection system, the ammonia water storage de...

Embodiment 2

[0079] The same desulfurization and denitrification system and process as in Example 1 were used. When the flue gas temperature in the regenerator chamber of the glass furnace burner drops to 1100°C, denitrification will be performed once, and the temperature of the flue gas leaving the glass furnace will be ˉ280°C. After electrostatic precipitation, the temperature of the flue gas is ˉ240°C, and it enters the ammonium sulfate decomposition ammonia production device. The flue gas exchanges heat with the desulfurization product ammonium sulfate solution, and the flue gas cooled to 150°C is mixed with the prepared oxidant hydrogen peroxide to make the hydrogen peroxide and the flue gas The molar ratio of NO is 1.35, and the NO in the flue gas is oxidized to NO 2 , and then enter the desulfurization and denitrification tower. The pH value of the desulfurization absorption liquid is maintained at about 6, and the desulfurization and secondary denitrification processes are complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com