Method for treating waste water through double catalytic oxidation process and device for achieving method

A dual-catalytic oxidation and wastewater treatment technology, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor wastewater adaptability, low treatment depth, and poor treatment effect , to achieve the effect of reducing processing costs, reducing processing costs, and reducing cell voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Biochemical waste water of a rubber factory sewage styrene-butadiene workshop: water volume 150m 3 / h, COD is 95mg / L, conductivity is 5500μs / cm, and chloride ion content is 110mg / L.

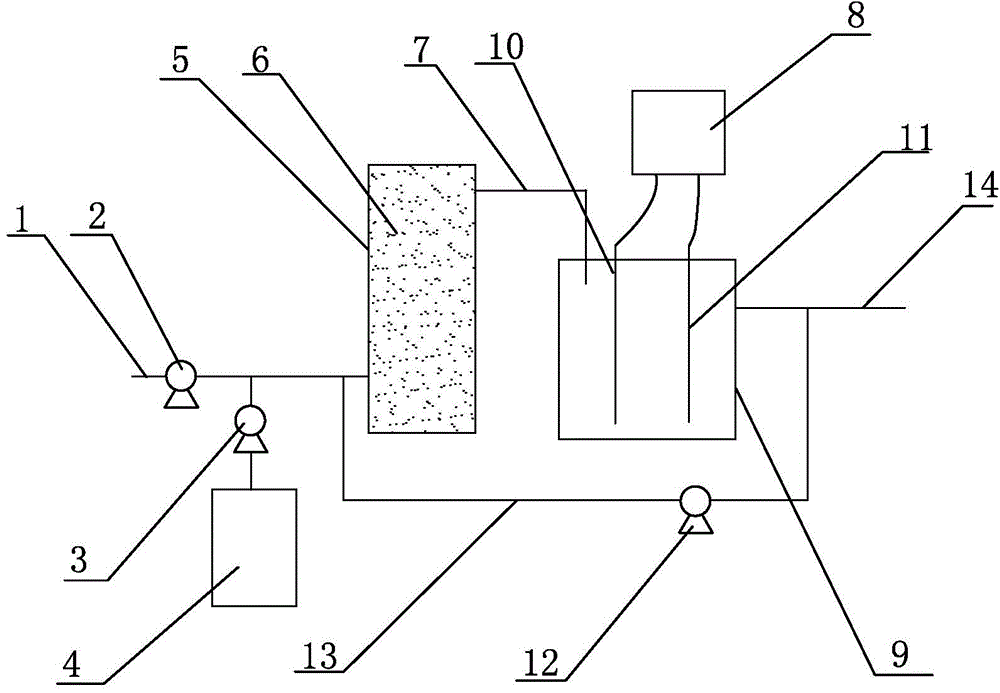

[0032] Devices for the treatment of wastewater by double catalytic oxidation process: such as figure 1 As shown, it includes a sodium hypochlorite catalytic oxidation reactor 5 and an electrolytic catalytic oxidation reactor 9. The bottom of the sodium hypochlorite catalytic oxidation reactor 5 is connected to the water inlet pipe 1, and the water inlet pipe 1 is provided with a water inlet pump 2, and the sodium hypochlorite storage tank 4 is sequentially connected to dosing through pipelines. The metering pump 3 and the water inlet pipe 1, the upper part of the sodium hypochlorite catalytic oxidation reactor 5 is connected to the upper part of the electrolytic catalytic oxidation reactor 9 through the overflow pipe 7, the electrolytic catalytic oxidation reactor 9 is connected to the wat...

Embodiment 2

[0036] Reverse osmosis concentrated water in a sewage reuse workshop of an oil refinery: water volume 100m 3 / h, COD is 120mg / L, conductivity is 8500μs / cm, and chloride ion content is 1200mg / L.

[0037] The device of the double catalytic oxidation process used in embodiment 2 is the same as that of embodiment 1.

[0038] The catalyst used is based on γ-Al 2 o 3 As a carrier, copper oxide is loaded as an active component. The volume ratio of the catalyst to the waste water is 200%, and the weight of the sodium hypochlorite is 0.1% of the waste water. The electrolytic catalytic anode material is a titanium-based coated electrode, and the coating composition is IrO 2 , The cathode material is titanium mesh.

[0039] Treatment process: the waste water to be treated enters 100m through the water inlet pipe 1 and the water inlet pump 2 3 At the bottom of the sodium hypochlorite catalytic oxidation reactor 5, it flows through the filled layer of the sodium hypochlorite catalyst...

Embodiment 3

[0041] Wastewater from the extraction workshop of a rare earth smelter: water volume 200m 3 / h, COD is 220mg / L, conductivity is 41000μs / cm, chloride ion content is 16000mg / L.

[0042] The device of the double catalytic oxidation process used in embodiment 3 is the same as that of embodiment 1.

[0043] The catalyst used is based on γ-Al 2 o 3 As the carrier, the loaded iron oxide and cobalt oxide are the active components. The volume ratio of the catalyst to the waste water is 100%, and the weight of the sodium hypochlorite is 0.01% of the waste water. The electrolytic catalytic anode material is a titanium-based coated electrode, and the coating composition is SnO 2 , the cathode material is a titanium plate.

[0044] Treatment process: the waste water to be treated enters 400m through the water inlet pipe 1 and the water inlet pump 2 3 At the bottom of the hypochlorous acid catalytic oxidation reactor 5, it flows through the filled layer of the hypochlorous acid cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com