Stably modified polyformaldehyde material and preparation method thereof

A polyoxymethylene material and a stabilization technology are applied in the field of stabilized and modified polyoxymethylene materials and their preparation, which can solve the problems of poor stability of the polyoxymethylene material, and achieve good stability, good heat resistance and aging resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A stabilized modified polyoxymethylene material prepared from the following raw material components in parts by weight: 62 parts of polyoxymethylene, 5 parts of carbon black, 4 parts of triethanolamine, 3 parts of dicyandiamide, and 4 parts of ammonium molybdate , 2 parts of triphenyl phosphate, 3 parts of methyl stearate, 2 parts of 2-hydroxy-4-methoxybenzophenone, 3 parts of calcium hydroxide, 2 parts of magnesium carbonate, 3 parts of zinc sulfate, organic titanium 2 parts, 3 parts of urea, 2 parts of strange ice stone and 1 part of antioxidant.

[0019] Wherein, the antioxidant is triethylene glycol-di-3-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate.

[0020] The preparation method of above-mentioned polyoxymethylene material, comprises the following steps:

[0021] Step 1: Weighing raw materials according to certain parts by weight;

[0022] Step 2: Add each raw material in step 1 into a high-speed mixer, and blend for 10 minutes to obtain a blend;

[0023]...

Embodiment 2

[0026] A stabilized modified polyoxymethylene material prepared from the following raw material components in parts by weight: 85 parts of polyoxymethylene, 9 parts of carbon black, 13 parts of triethanolamine, 9 parts of dicyandiamide, and 8 parts of ammonium molybdate , 10 parts of triphenyl phosphate, 8 parts of methyl stearate, 9 parts of 2-hydroxy-4-methoxybenzophenone, 10 parts of calcium hydroxide, 6 parts of magnesium carbonate, 9 parts of zinc sulfate, organic titanium 7 parts, 8 parts of urea, 7 parts of strange ice stone and 5 parts of antioxidant.

[0027] Wherein, the antioxidant is triethylene glycol-di-3-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate.

[0028] The preparation method of above-mentioned polyoxymethylene material, comprises the following steps:

[0029] Step 1: Weighing raw materials according to certain parts by weight;

[0030] Step 2: adding each raw material in step 1 into a high-speed mixer, and blending for 20 minutes to obtain a blend;...

Embodiment 3

[0034] A stabilized modified polyoxymethylene material prepared from the following raw material components in parts by weight: 74 parts of polyoxymethylene, 7 parts of carbon black, 8 parts of triethanolamine, 6 parts of dicyandiamide, and 6 parts of ammonium molybdate , 6 parts of triphenyl phosphate, 5 parts of methyl stearate, 5 parts of 2-hydroxy-4-methoxybenzophenone, 6 parts of calcium hydroxide, 4 parts of magnesium carbonate, 6 parts of zinc sulfate, organic titanium 4 parts, 5 parts of urea, 4 parts of strange ice stone and 3 parts of antioxidant.

[0035] Wherein, the antioxidant is triethylene glycol-di-3-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate.

[0036] The preparation method of above-mentioned polyoxymethylene material, comprises the following steps:

[0037] Step 1: Weighing raw materials according to certain parts by weight;

[0038] Step 2: Add each raw material in step 1 into a high-speed mixer, and blend for 15 minutes to obtain a blend;

[0039...

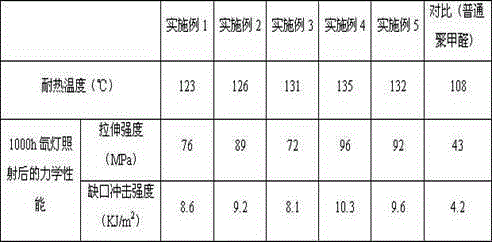

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com