Method for detecting lithium extraction of negative electrode of lithium ion battery

A technology of lithium-ion batteries and detection methods, which is applied in the direction of material analysis, measurement devices, and analysis materials using wave/particle radiation, which can solve problems such as battery safety threats, difficult detection, and electronic insensitivity, and achieve simple and easy Perform detection methods, avoid security problems, and the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Provided in the present embodiment is to realize the detection method of lithium on the surface of lithium sheet according to the following steps:

[0039] 1. DMC solution configuration of zinc nitrate: dry zinc nitrate (dried at 110-130°C), after drying, take out 10g of zinc nitrate and dissolve it in 100mL of dimethyl carbonate (DMC) solution to form zinc nitrate of organic solutions.

[0040] 2. Reaction of lithium flakes with zinc nitrate: soak metal lithium flakes in the DMC solution of zinc nitrate, find that the surface of lithium flakes with metallic luster turns black rapidly, and after 30 minutes, the surface of lithium flakes almost all turns black, and there is no change in continuing immersion. To ensure that the reaction is complete, the soaking time used in the experiment is 1-2 hours. The scanning electron microscope test was carried out on the lithium sheet before and after immersion, and the figure 1 It can be seen that the surface of the original li...

Embodiment 2

[0042] The detection of lithium precipitation on the normal charge and discharge negative electrode and the excessive lithium intercalation negative electrode is realized according to the following steps:

[0043] 1. Preparation of MCMB (mesophase carbon microspheres) button half-battery: the ratio of MCMB electrode material is MCMB:AB:PVDF=85:5:10, and assembled into a 2025-type button battery. Among them, the research electrode is MCMB pole piece, the reference electrode is Li piece, and the electrolyte is 1mol / LLiPF 6(EC / DEC / EMC, volume ratio 1:1:1), the diaphragm is made of polypropylene. The coin cell (MCMB / Li) was formed 3 times.

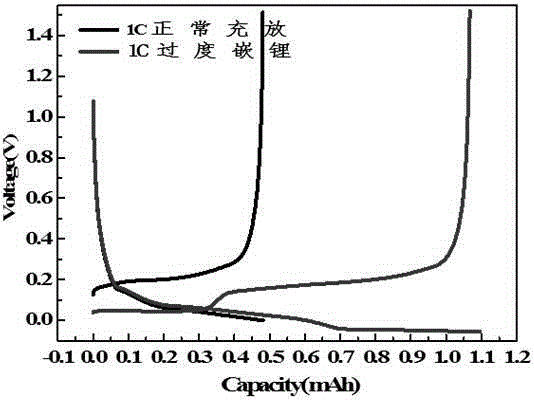

[0044] 2. Carry out 1C0-1.5V charge and discharge and excessive lithium intercalation charge and discharge 3 times on the formed button battery, such as image 3 shown. image 3 The discharge curve of the medium-excessive lithium intercalation showed a plateau below 0V after discharging to 0.7mAh, which was presumed to be the deposition of ...

Embodiment 3

[0050] 1. Lithium cobalt oxide / MCMB full battery is charged and discharged 3 times at -20°C and 0.3C. Disassemble the battery in a fully discharged state, cut off part of the negative electrode and wash it 3 times in DMC to remove the residual electrolyte.

[0051] 2. Soak the negative electrode in the DMC solution of zinc chloride for 1-2 hours, take it out, and wash it with DMC for 3 times to remove the residual zinc chloride on the surface.

[0052] 3. The pole piece treated with zinc chloride is subjected to scanning electron microscope test, and it can be seen that strip-like substances are formed at a certain position on the surface. Figure 9-11 The distribution of Zn element on the surface of the middle electrode is the same as the distribution of the strip-shaped substance in the scanning electron microscope, and then it is determined that the strip-shaped substance corresponds to zinc, the product of the reaction between lithium and zinc ions, and the distribution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com