Guided mode resonance wave shifting device for scintillation detection

A technology of guided mode resonance and scintillation detection, which is applied in the field of nuclear radiation detection, can solve the problems of the difficulty in measuring fluorescence in the vacuum ultraviolet band, the inability to control the directionality of light emission, and low time resolution, and achieve good radiation resistance. Improving the time resolution ability and the effect of mature process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

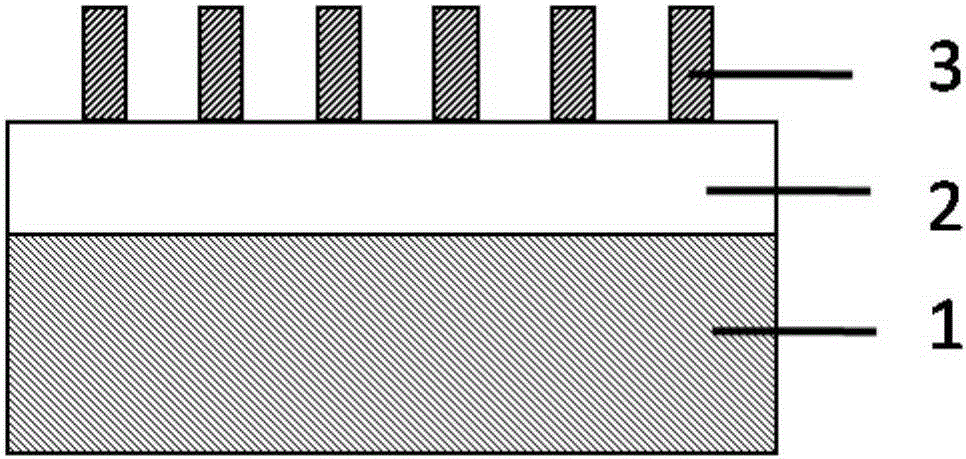

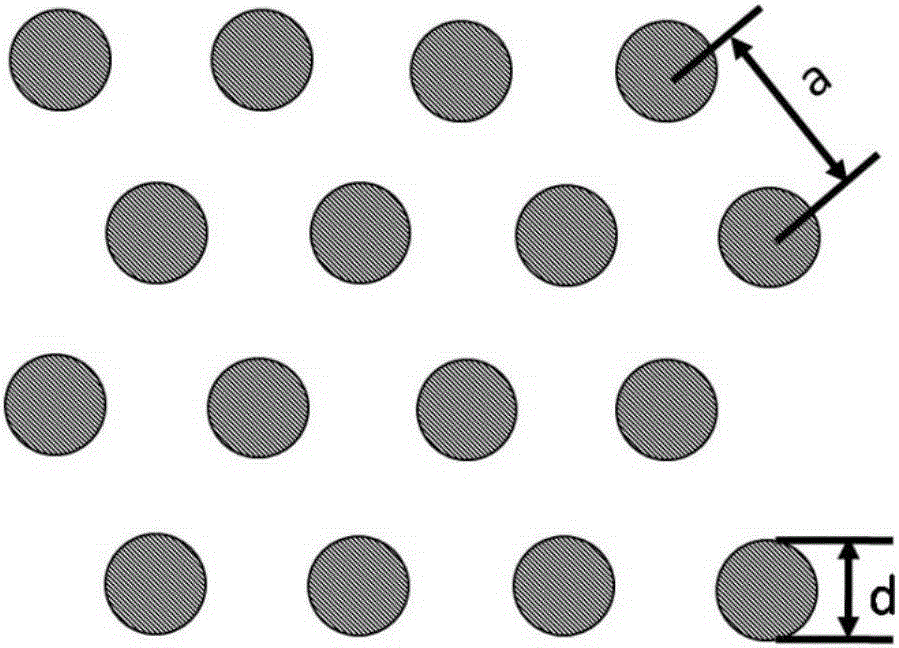

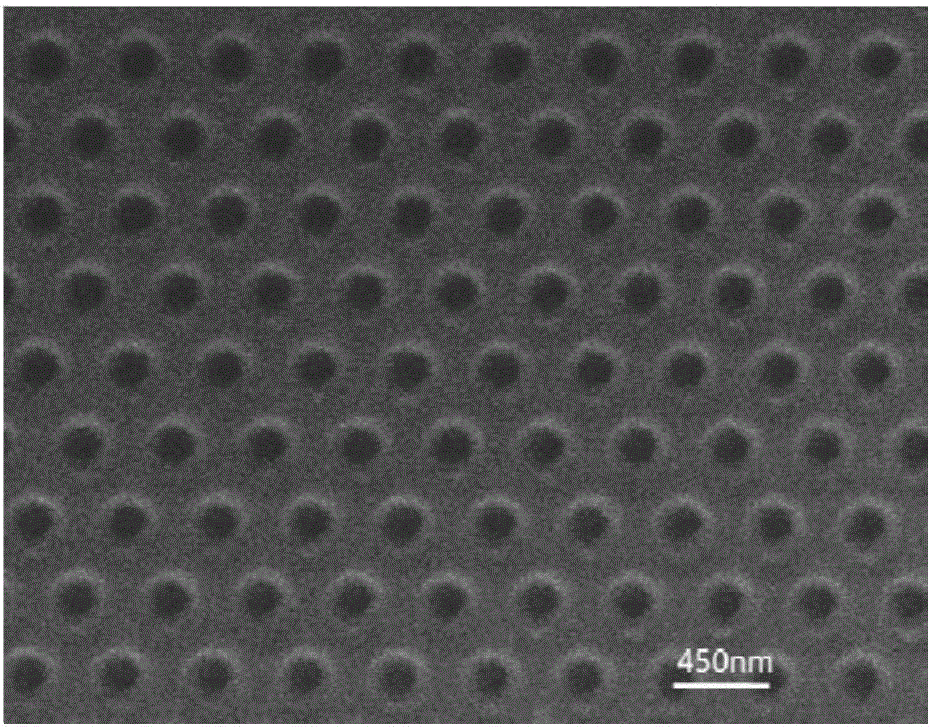

[0027] The structure diagram of the present invention is as figure 1 As shown, it includes a base layer 1, a luminescent film layer 2, and a photonic crystal layer 3. The luminescent film layer 2 is arranged on the base layer 1, and the photonic crystal layer 3 is arranged on the luminescent film layer. figure 2 It is a schematic diagram of the structure of the photonic crystal in the present invention, wherein a is the period of the periodic array of triangular configuration in the photonic crystal layer, and d is the diameter of the dielectric column.

[0028] The selected material and structural parameters of this embodiment are as follows: select CaF 2 The crystal is the base layer, and the luminescent film layer is (Lu 0.9 Ce 0.1 ) 2 SiO 5 The thickness is chosen as The period of the photonic crystal is 430nm, the diameter of the dielectric column is 215nm, the height is 210nm, and the dielectric material is SiN.

[0029]The preparation process is as follows: (1) ...

Embodiment 2

[0031] The material and structural parameters selected in this embodiment are as follows: LiF crystal is selected as the base layer, and the luminescent film layer is (Lu 0.9 Ce 0.1 ) 2 SiO 5 The thickness is chosen as The period of the photonic crystal is 350nm, the diameter of the dielectric column is 175nm, the height is 210nm, and the dielectric material is SiN.

[0032] The sample preparation method is the same as in Example 1, except that the concentration of PEG400 used in the preparation of the luminescent film is reduced to obtain a film thickness of 159 nm. The pattern during electron beam exposure during photonic crystal preparation can be implemented according to the design parameters of this example.

[0033] Figure 5 It is the angle dependence of the luminescence spectrum of the sample under the excitation of far ultraviolet light. The results show that it has obvious emission at an angle of 36°, and the luminous intensity at this angle accounts for about ...

Embodiment 3

[0035] This embodiment is basically the same as Embodiment 1, the difference is that the diameter of the dielectric column of the photonic crystal layer is 236nm, the height of the dielectric column is 252nm, and the obtained guided mode resonance wave shifting device for scintillation detection has high conversion Efficiency and time resolution, and a high degree of light emission direction control ability, can improve the detection efficiency of ultraviolet and other scintillation fluorescence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com