Preparation method of large-scale methanol catalyst

A catalyst and methanol conversion technology, which is applied in the preparation of organic compounds, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low selectivity of dimethyl ether and ethanol, unsuitable for large-scale synthetic methanol production and use, etc. , to achieve the effect of improving methanol selectivity, good thermal conductivity, and improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

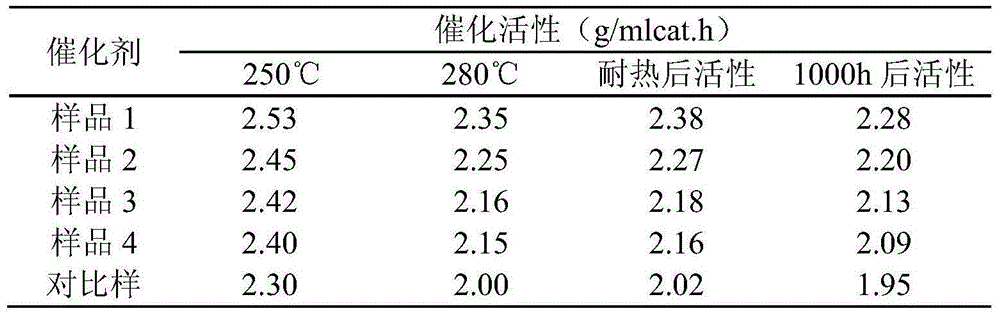

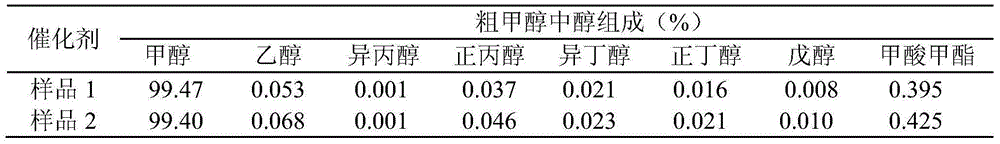

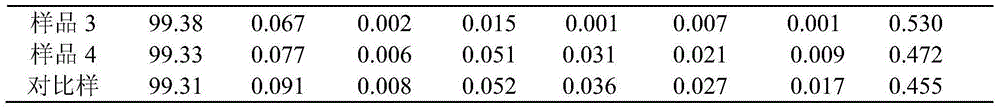

Examples

Embodiment 1

[0029] Weigh Mg(NO 3 ) 2 ·6H 2 O9.05g, Al(NO 3 ) 2 9H 2 O26.49g, dissolved in a 50ml desalinated beaker, stirred to make it completely dissolved, supplemented with desalted water and set the volume to 260ml, to prepare salt solution A. Weigh Na 2 CO 3 16.30g, dissolved in a 50ml desalinated beaker, stirred to dissolve completely, supplemented with desalinated water and set the volume to 260ml, to prepare alkaline solution A. Weigh Cu(NO 3 ) 2 ·3H 2 O147.92g, Zn(NO 3 ) 2 ·6H 2 O89.10g, Al(NO 3 ) 2 9H 2 O38.28g was dissolved in a 200ml desalinated beaker, stirred to make it completely dissolved, supplemented with desalted water and set the volume to 1000ml, and the salt solution B was prepared. Weigh Na 2 CO 3 123.66g, dissolved in a 200ml desalinated beaker, stirred to dissolve completely, supplemented with desalinated water and set the volume to 1000ml, to prepare alkaline solution B.

[0030]Preheat the salt solution A and alkali solution A to a reaction te...

Embodiment 2

[0034] Weigh Mg(NO 3 ) 2 ·6H 2 O13.08g, Al(NO 3 ) 2 9H 2 O38.28g, dissolved in a 50ml desalinated beaker, stirred to make it completely dissolved, supplemented with desalted water and constant volume to 375ml, prepared to obtain salt solution A. Weigh Na 2 CO 3 23.55g, dissolved in a 50ml desalinated beaker, stirred to dissolve completely, supplemented with desalinated water and set the volume to 375ml, to prepare alkaline solution A. Weigh Cu(NO 3 ) 2 ·3H 2 O147.92g, Zn(NO 3 ) 2 ·6H 2 O89.10g, Al(NO 3 ) 2 9H 2 O38.28g was dissolved in a 200ml desalinated beaker, stirred to make it completely dissolved, supplemented with desalted water and set the volume to 1000ml, and the salt solution B was prepared. Weigh Na 2 CO 3 123.66g, dissolved in a 200ml desalinated beaker, stirred to dissolve completely, supplemented with desalinated water and set the volume to 1000ml, to prepare alkaline solution B.

[0035] Preheat the salt solution A and alkali solution A to a ...

Embodiment 3

[0039] Weigh Sr(NO 3 ) 2 5.18g, Al(NO 3 ) 2 9H 2 O18.37g, dissolved in a 50ml desalinated beaker, stirred to make it completely dissolved, supplemented with desalted water and constant volume to 240ml, prepared to obtain salt solution A. Weigh Na 2 CO 3 11.30g, dissolved in a 50ml desalinated beaker, stirred to dissolve completely, supplemented with desalinated water and set the volume to 240ml, to prepare alkaline solution A. Weigh Cu(NO 3 ) 2 ·3H 2 O147.92g, Zn(NO 3 ) 2 ·6H 2 O89.10g, Al(NO 3 ) 2 9H 2 O38.28g was dissolved in a 200ml desalinated beaker, stirred to make it completely dissolved, supplemented with desalted water and set the volume to 1000ml, and the salt solution B was prepared. Weigh Na 2 CO 3 123.66g, dissolved in a 200ml desalinated beaker, stirred to dissolve completely, supplemented with desalinated water and set the volume to 1000ml, to prepare alkaline solution B.

[0040] Preheat the salt solution A and alkali solution A to a reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com