Preparation method of hollow porous carbon spheres with high specific surface area

A high specific surface area, hollow carbon sphere technology, applied in the field of inorganic materials, can solve the problems of inability to control the surface parameters of spheres, low specific surface area of hollow carbon spheres, cumbersome steps, etc., to achieve controllable particle size and wall thickness, and easy to obtain raw materials , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

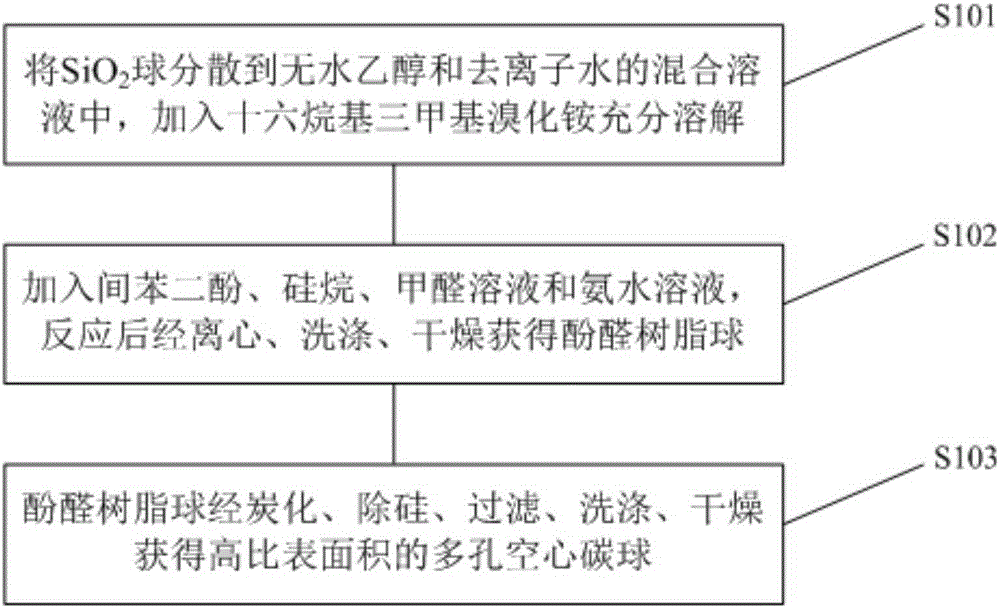

[0033] Such as figure 1 As shown, the present invention discloses a method for preparing porous hollow carbon spheres with a high specific surface area. The method includes:

[0034] S101, SiO 2 Disperse the ball into a mixed solution of absolute ethanol and deionized water, add cetyltrimethylammonium bromide to fully dissolve; the specific steps are:

[0035] SiO with a diameter of 50nm~1000nm 2 Put the ball in the beaker, add absolute ethanol, deionized water, SiO 2 The mass ratio of ball and absolute ethanol is 0.05: 9.875, the volume ratio of absolute ethanol and deionized water is (12.5~15): (30~40), ultrasonic vibration 15min makes SiO 2 The balls are fully dispersed into the mixed solution of absolute ethanol and deionized water, and cetyltrimethylammonium bromide is added. The mass fraction of cetyltrimethylammonium bromide in the reaction system is (0.04~0.18 )% to make it fully dissolved;

[0036] S102, adding resorcinol, silane, formaldehyde solution and ammonia solution, ...

Embodiment 1

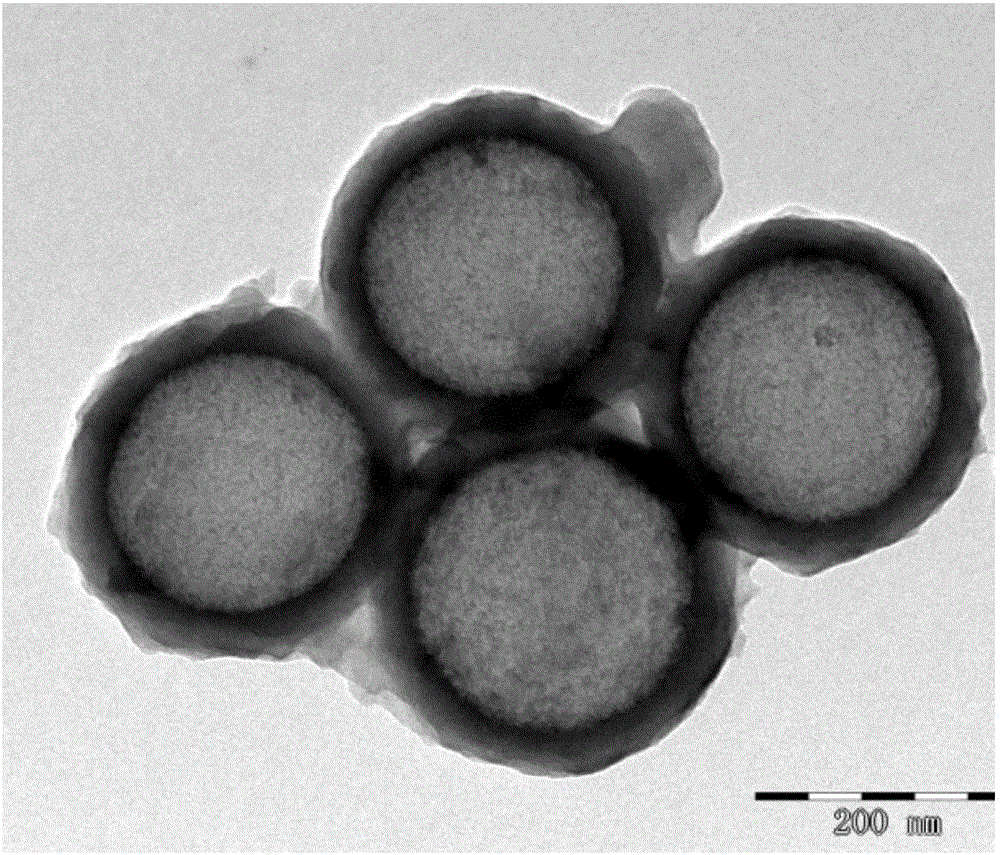

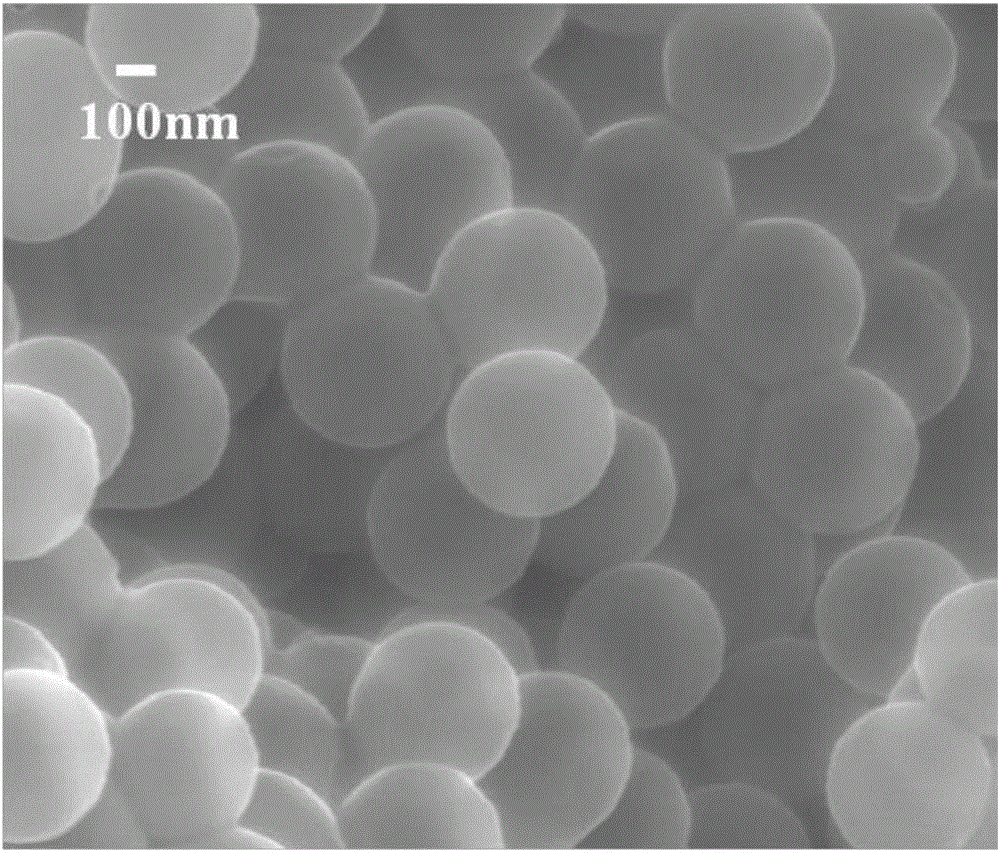

[0044] Example 1: The method for preparing porous hollow carbon spheres with high specific surface area described in the embodiment of the present invention is as follows: take 0.0500 g of silica spheres with a diameter of about 180 nm in a small beaker and add no Water ethanol 12.5mL, deionized water 30mL ultrasonic for 15min, pour the solution into the flask, and add 0.0750g cetyltrimethylammonium bromide to the flask, after it is fully dissolved, add 0.0160g resorcinol , Ethyl orthosilicate 17μL, after stirring for 10min, add 61μL formaldehyde, 230μL ammonia water, stirring at room temperature for 24h, centrifuge the resulting product, wash 3 times with absolute ethanol, dry at 70℃ for 12h to prepare phenolic resin ball; Carbonized in a nitrogen atmosphere, heated to 350°C at a rate of 1°C / min, kept for 2h, and then heated to 600°C at a rate of 1°C / min, kept for 4h; put the resulting product in a 10% (mass fraction) hydrofluoric acid solution After stirring for 24h, filter, ...

Embodiment 2

[0045] Example 2: The method for preparing porous hollow carbon spheres with high specific surface area described in the embodiment of the present invention is as follows: take 0.0500 g of silica spheres with a diameter of about 180 nm in a small beaker and add no Water ethanol 12.5mL, deionized water 30mL ultrasonic for 15min, pour the solution into the flask, and add 0.0750g cetyltrimethylammonium bromide to the flask, after it is fully dissolved, add 0.0480g resorcinol , Methyl orthosilicate 17μL, after stirring for 10min, add 183μL formaldehyde, 230μL ammonia water, stirring at room temperature for 24h, centrifuge the resulting product, wash 3 times with absolute ethanol, dry at 70℃ for 12h to prepare phenolic resin ball; Carbonized in a nitrogen atmosphere, heated to 350°C at a rate of 1°C / min, kept for 2h, and then heated to 600°C at a rate of 1°C / min, kept for 4h; put the resulting product in a 10% (mass fraction) hydrofluoric acid solution Stir for 24h, filter, wash and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com