Method for preparing two-dimensional nanomaterial film on basis of liquid phase method

A two-dimensional nanomaterial and two-dimensional nanotechnology are applied in the field of large-area rapid preparation of two-dimensional nanomaterial thin films, which can solve the problems of high film production cost, poor film uniformity, and unfriendly environment, and achieve short preparation cycle and low cost , highly reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) select the ethanol solution of 0.1mg / mL graphene for use;

[0027] 2) Single crystal silicon is selected as the substrate for film transfer;

[0028] 3) Place the monocrystalline silicon substrate on the bottom of the petri dish, pour water into the petri dish, and slowly inject the previously configured graphene ethanol solution along the wall of the cup with a dropper. At this time, a layer with a thickness of about Uniform graphene films with a thickness of several nanometers;

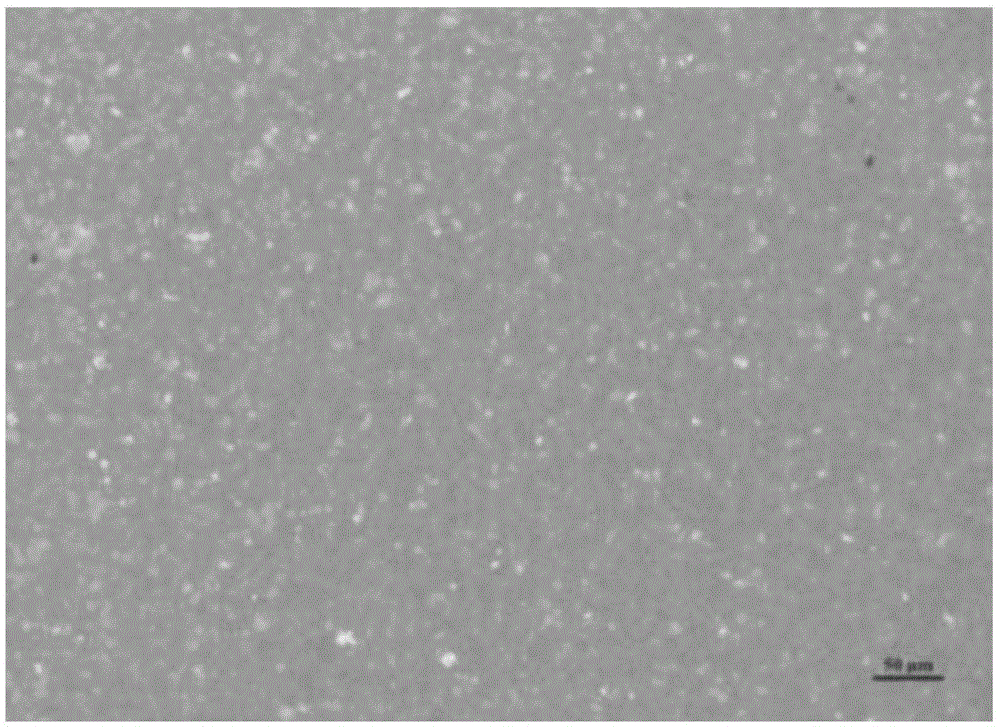

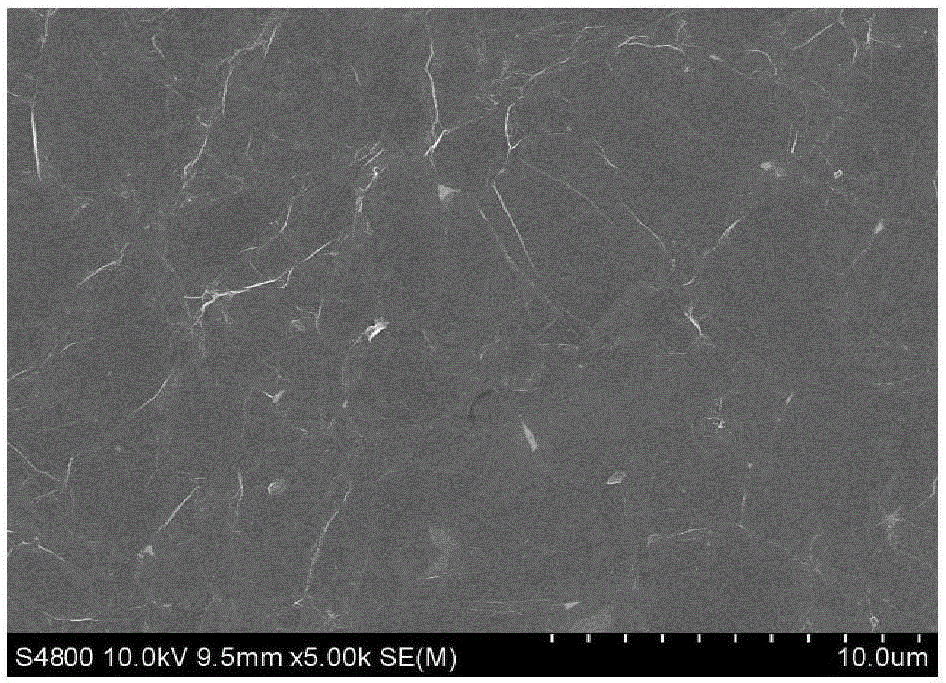

[0029] 4) Take out the water at the bottom of the petri dish with a syringe, the graphene film is closely attached to the silicon substrate, take out the substrate, and let it dry to obtain the final product graphene film (such as figure 1 , 2 , 3 shown).

Embodiment 2

[0031] 1) select the acetone solution of 10mg / mL graphene for use;

[0032] 2) Select polydimethylsiloxane as the substrate for film transfer;

[0033] 3) Put the polydimethylsiloxane at the bottom of the petri dish, inject 1mol / L sodium chloride solution into the petri dish, and slowly inject the graphene acetone solution prepared before with a dropper along the wall of the cup. A uniform graphene film with a thickness of several nanometers is formed on the surface of the liquid phase;

[0034] 4) Draw out the sodium chloride solution at the bottom of the petri dish with a syringe, the graphene film is closely attached to the polydimethylsiloxane, take out the substrate, and let it dry to obtain the final graphene film;

[0035] 5) Apply silver glue and silver wires on both ends of the graphene film, place the graphene / polydimethylsiloxane sample in a stretching machine, and connect the silver wires to the resistance tester at the same time, as the stretching machine stretch...

Embodiment 3

[0037] 1) select the isopropanol solution of 1mg / mL graphene for use;

[0038] 2) Select polyethylene terephthalate as the substrate for film transfer;

[0039] 3) Put the polyethylene terephthalate base material on the bottom of the petri dish, inject 0.1mol / L potassium chloride solution into the petri dish, and extend the graphene isopropanol solution prepared before with a dropper. The cup wall is slowly injected, and at this time, a uniform graphene film with a thickness of several nanometers is formed on the surface of the liquid phase;

[0040] 4) Draw out the potassium chloride solution at the bottom of the petri dish with a syringe, the graphene film is closely attached to the polyethylene terephthalate base material, take out the base material, and let it stand and dry to obtain the final graphene film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com