Sludge recycle treatment method

A treatment method and recycling technology, applied in the field of sludge recycling, can solve problems such as damage to sewage treatment equipment, difficulty in recycling, and impact on sewage treatment effects, and achieve good water holding capacity and long-lasting fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

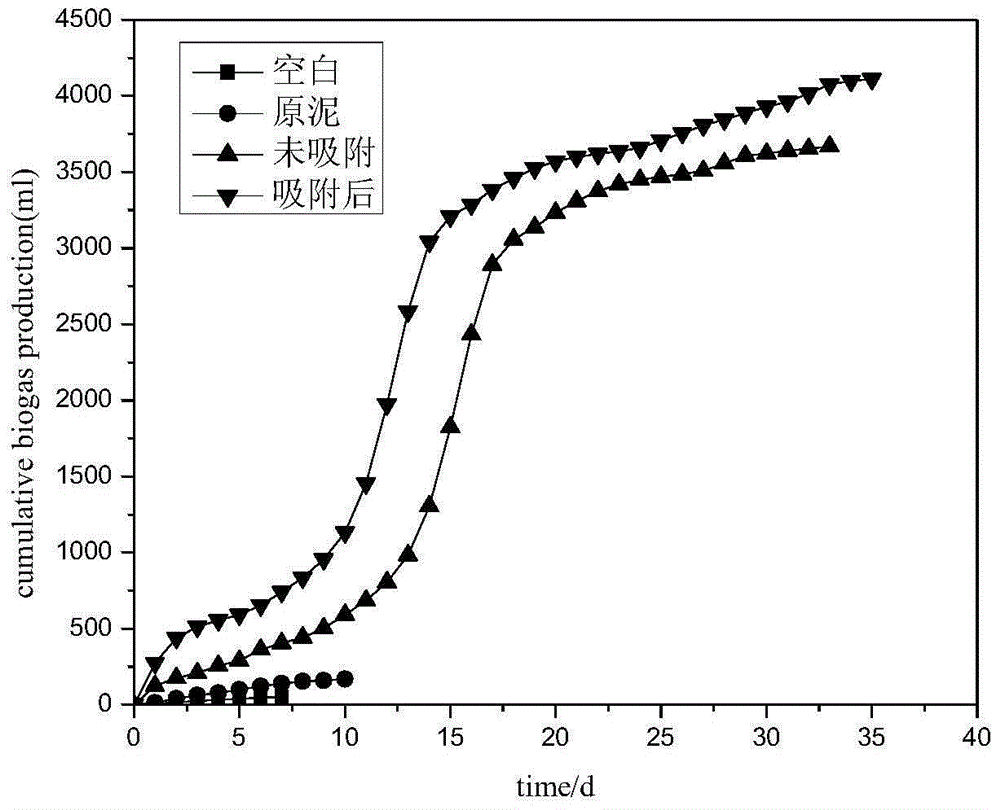

[0032] Example 1 Effect of composite adsorbent on anaerobic fermentation

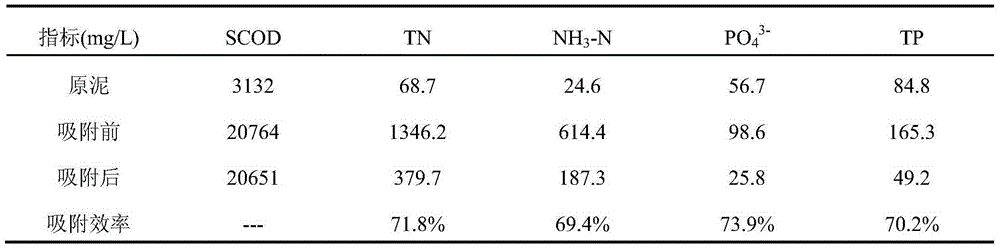

[0033] Take the dewatered raw sludge from the sewage treatment plant, adjust the solid-to-liquid ratio to 15%, conduct hydrothermal treatment at 160°C for 1 h, and separate the hydrothermal sludge from solid and liquid. First, measure the indicators SCOD and TN in the liquid phase. , NH 3 -N, PO 4 3- TP, and then add a composite adsorption material prepared from waste glass and dolomite with a weight ratio of 1:1 for adsorption. After the adsorption is completed, continue to measure four indicators to obtain adsorption efficiency and nitrogen and phosphorus concentration after adsorption. The results are shown in Table 1. Show.

[0034] Table 1 Comparison table of sludge composition before and after adsorption before anaerobic fermentation

[0035]

[0036] The data in Table 1 shows that after the sludge is subjected to hydrothermal treatment, the concentration of carbon, nitrogen, and phosphorus in the liqui...

Embodiment 2

[0039] Implementation 2 The effect of composite adsorbents on the concentration of nitrogen and phosphorus after anaerobic gas production

[0040] Separate the solid-liquid sludge after anaerobic gas production in Example 1, and measure the SCOD, TN, and NH in the liquid phase. 3 -N, PO 4 3- TP index, and then add a composite adsorption material prepared from waste glass and dolomite with a weight ratio of 1:1. After the adsorption step, continue to measure four indicators to obtain the adsorption efficiency and the concentration of nitrogen and phosphorus after adsorption. The results are shown in Table 2. Shown.

[0041] Table 2 Comparison table of sludge composition before and after adsorption after anaerobic fermentation

[0042]

[0043] The data in Table 2 shows that after anaerobic gas production, the concentration of ammonia nitrogen and phosphate in the liquid phase of the sludge increases, and the addition of composite adsorbents can further remove the concentration of nitr...

Embodiment 3

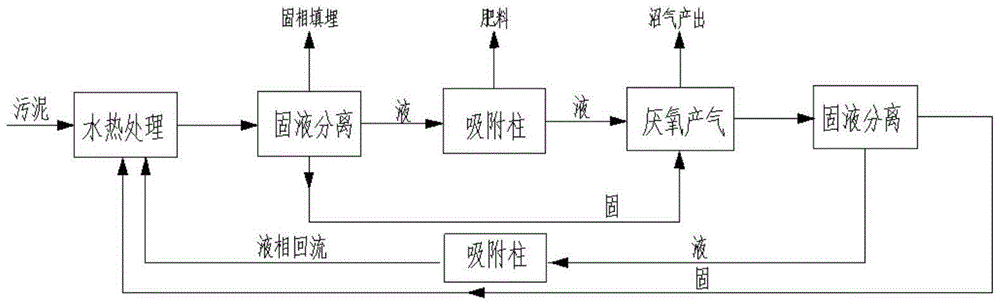

[0045] Implement 3 sludge recycling treatment methods

[0046] Take the dewatered raw sludge from the sewage treatment plant, adjust the solid-liquid ratio to 15%, hydrothermally heat the sludge at 160℃ for 1h, separate the sludge from solid and liquid, add composite adsorbents to the liquid phase, and mix the liquid and solid phases for anaerobic After 28 days of fermentation, the fermented sludge undergoes solid-liquid separation, the liquid phase is added to the composite adsorption material for adsorption again, and the adsorbed liquid phase and solid phase enter the next round of sludge treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com