Compound fertilizer for increasing sugar content of sugarcane and production method thereof

A technology of compound fertilizer and special fertilizer for sugarcane, applied in fertilization device, fertilizer mixture, application, etc., can solve problems such as poor effect, increased labor cost, and failure to improve soil, so as to promote germination, promote sugarcane growth, and facilitate the absorption of nutrients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

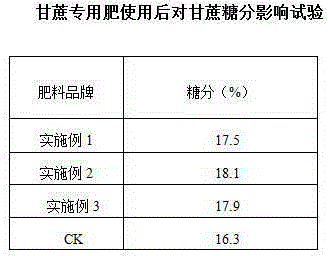

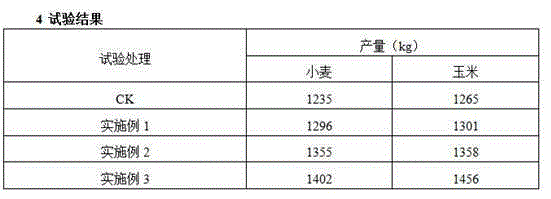

Embodiment 1

[0042] Formulated with 30% total N, P, and K nutrients (12-8-10), and 15% of organic matter in organic fertilizer, special sugar cane fertilizer (12-8-10) refers to N and P respectively 2 O 5 , K 2 The nutrient percentage of O, the same below).

[0043] Raw material formula ratio: 200 kg of urea (calculated as 46.0% with N), 175 kg of diammonium phosphate (calculated as 16% with N and P 2 O 5 According to 46.0%, 5 kg of calcium magnesium phosphate fertilizer (containing P 2 O 5 18.0%, 9% for Mg, 28.4% for Ca, 12.7% for Si), 200 kg of potassium sulfate (with K 2 O is 50.0%, S is 17.0%), borax is 1 kg (B is 11%), zinc sulfate heptahydrate is 0.5 kg (Zn is 23%), and ammonium molybdate is 0.5 kg (Mo is 54%). %), 0.5 kg of copper sulfate (23% containing Cu), 390 kg of organic fertilizer, 10 kg of cinnamon powder, and 20 kg of wintergreen oil.

[0044] The organic matter in the organic fertilizer is the product obtained by adding tobacco, seaweed, cassava residue and pond or seabed silt t...

Embodiment 2

[0048] Formulated with 35% total nitrogen, phosphorus and potassium nutrients (12-8-15) and 15% organic matter special fertilizer for sugarcane (12-8-15) refer to N and P respectively 2 O 5 , K 2 The nutrient percentage of O, the same below).

[0049] Raw material formula ratio: 200 kg of urea (calculated as 46.0% with N), 175 kg of diammonium phosphate (calculated as 16% with N and P 2 O 5 According to 46.0%, 5 kg of calcium magnesium phosphate fertilizer (containing P 2 O 5 18.0%, 9% for Mg, 28.4% for Ca, 12.7% for Si), 250 kg of potassium chloride (with K 2 O 60.0%), 2 kg of borax (11% containing B), 2 kg of zinc sulfate heptahydrate (23% containing Zn), 2 kg of ammonium molybdate (54% containing Mo), copper sulfate 2 Kg (23% containing Cu), 282 kg of organic fertilizer, 10 kg of eugenol, 20 kg of wintergreen oil, and 50 kg of turpentine.

[0050] The organic matter in the organic fertilizer is the product obtained by adding tobacco, seaweed, cassava residue and pond or seabed si...

Embodiment 3

[0056] Formulated with 38% (15-8-15) total nitrogen, phosphorus and potassium nutrients and 15% organic matter special fertilizer for sugarcane (15-8-15) refer to N and P respectively 2 O 5 , K 2 The nutrient percentage of O, the same below).

[0057] Raw material formula ratio: 270 kg of urea (calculated as 46.0% with N), 175 kg of diammonium phosphate (calculated as 16% with N and P 2 O 5 According to 46.0%, 5 kg of calcium magnesium phosphate fertilizer (containing P 2 O 5 18.0%, 9% for Mg, 28.4% for Ca, 12.7% for Si), 250 kg of potassium chloride (with K 2 O 60.0%), 2 kg of borax (11% containing B), 2 kg of zinc sulfate heptahydrate (23% containing Zn), 2 kg of ammonium molybdate (54% containing Mo), copper sulfate 2 Kg (23% containing Cu), 212 kg of organic fertilizer, 10 kg of eugenol, 20 kg of wintergreen oil, and 50 kg of turpentine.

[0058] The organic matter in organic fertilizer is the product obtained by adding tobacco, seaweed, cassava residue and pond or seabed sludge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com