Application of macromolecule-based infrared absorption material to preparation of full-macromolecule heat-insulating film

An infrared absorption, polymer-based technology, which is applied in the application field of polymer-based infrared absorption materials in the preparation of all-polymer thermal insulation films, can solve the problems of unfavorable large-area preparation, unfavorable popularization and application, high cost, etc., and achieves good visible light transmission. Transient and infrared light shielding performance, low price, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

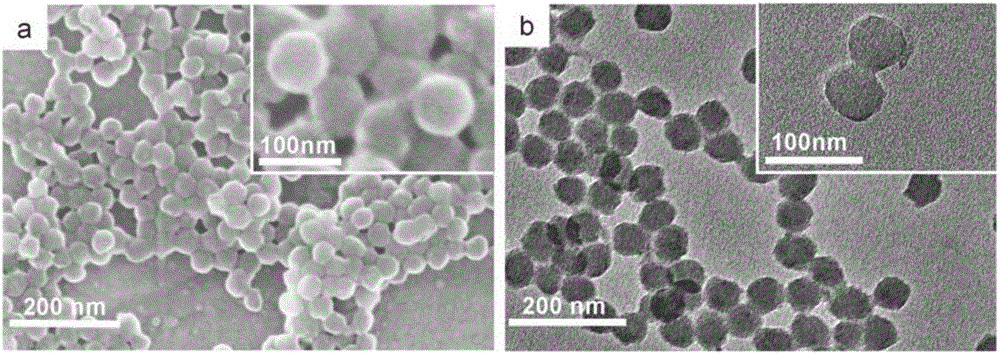

[0030] Weigh 1.2347gFeCl 3 ·6H 2 O and 1.5 g of polypropylene alcohol (PVA) were then added to 50 mL of deionized water, and stirred at room temperature for 1 hour to form a light yellow solution. Then, at 5°C, 140 μL of pyrrole monomer was added and reacted under stirring for 4 hours. After the reaction, centrifuged to obtain polypyrrole nanoparticles, the morphology is as follows figure 1 as shown, figure 1 a is a scanning electron microscope picture of polypyrrole, from which it can be seen that it is uniform spherical nanoparticles with uniform size (about 50nm); the transmission electron microscope picture in 1b further confirms that the prepared polypyrrole of the present invention is a uniform size ( 50nm or so) distributed spherical particles.

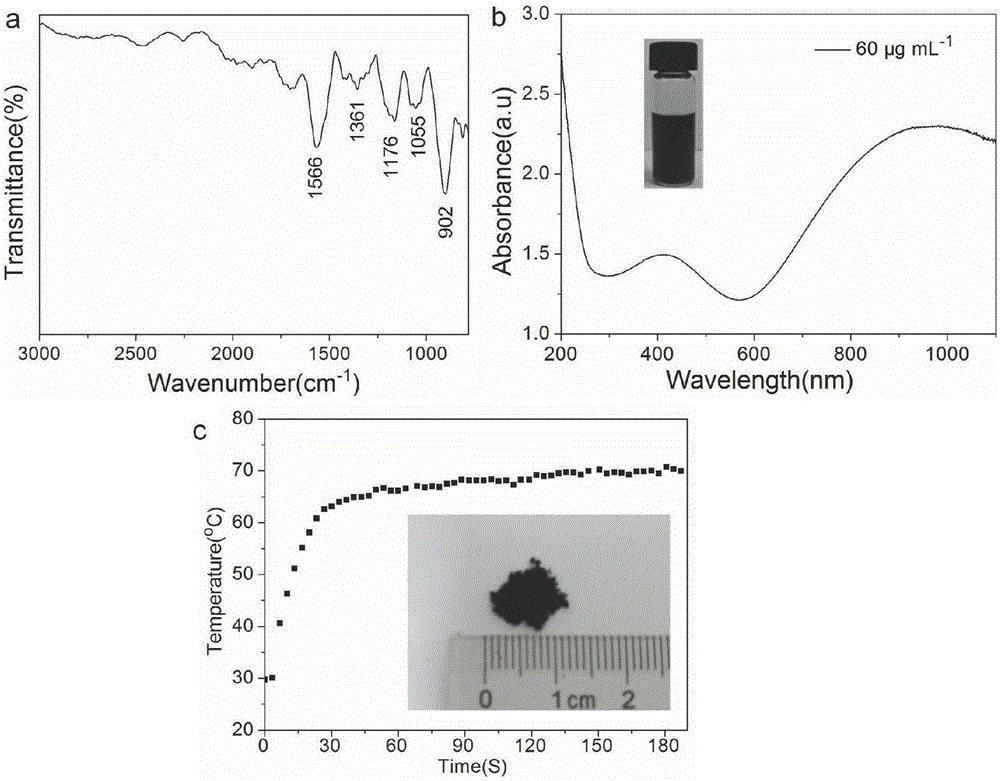

[0031] exist figure 2 In a, mix the polypyrrole powder prepared by the present invention with potassium bromide to make tablets, and test the infrared diagram. It can be seen from several characteristic absorption peak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com