Separation method for high-water-content crude oil

A high-water-cut crude oil and separation method technology, which is applied in the field of rapid separation of oil, gas and water extracted from high-water-cut oilfields, can solve the problems of complex manufacturing process of electrode modules, certain requirements for gas content, and impact on enterprise benefits, so as to avoid electric field intensity Drop or short circuit, ensure safety and running stability, and facilitate operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

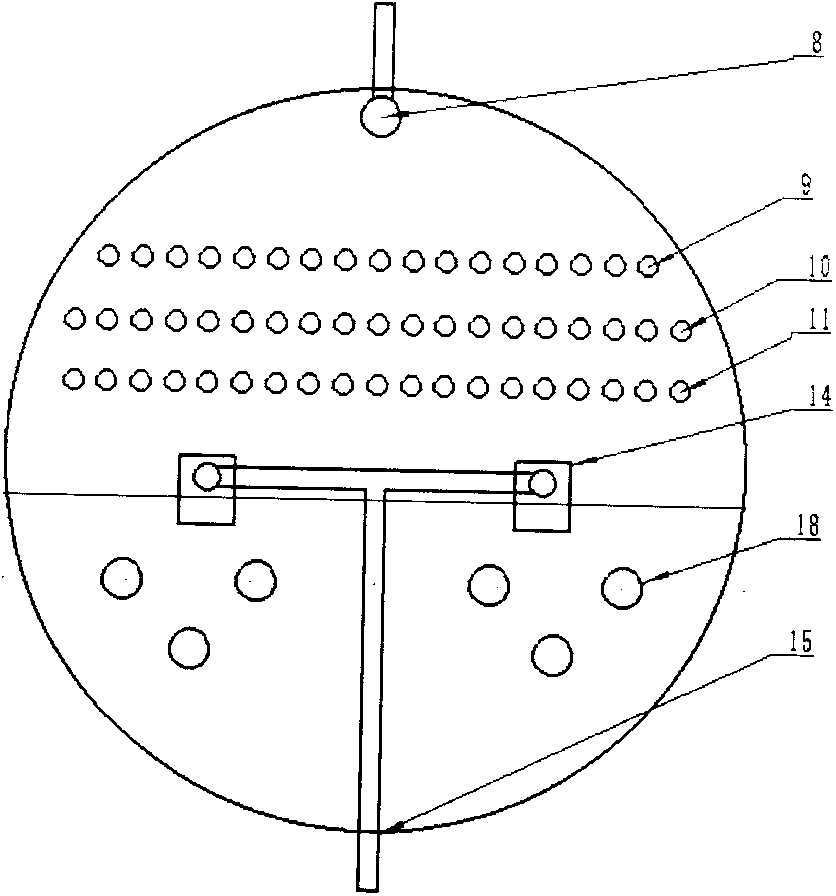

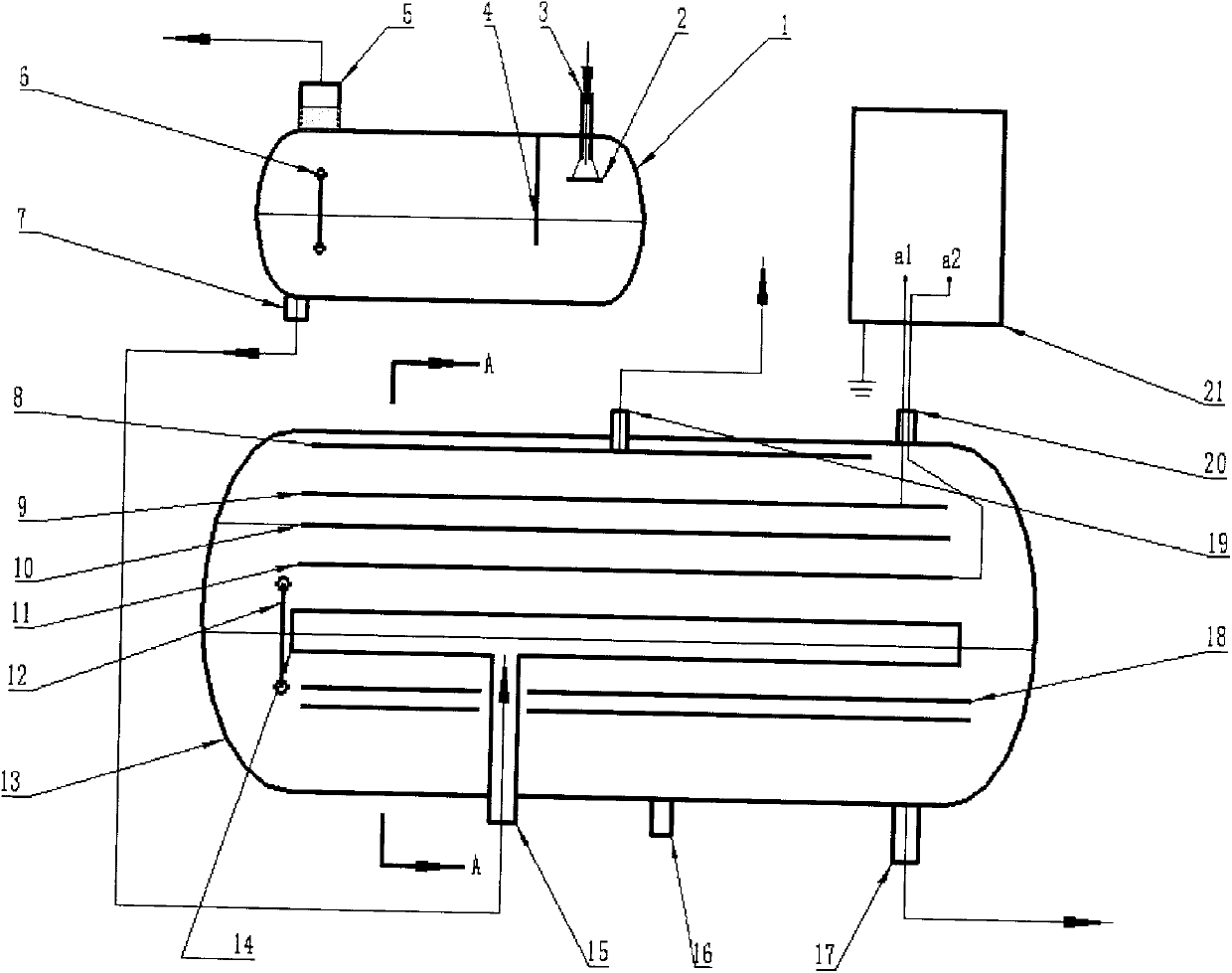

Method used

Image

Examples

Embodiment 1

[0031] In an offshore oilfield A in the south, due to the late stage of production, the water content of the produced well fluid is as high as 90%, and the density of crude oil at room temperature is 0.941g / cm 3 , using a conventional oil-gas-water three-phase separator, the operating pressure is 0.25MPa, the separation temperature is 55°C, and the liquid phase residence time is 40 minutes.

[0032] Using the equipment of the present invention to treat the same well fluid, the operating pressure is 0.25MPa, the separation temperature is 55°C, and the field test results of different liquid phase residence times are shown in the table below.

[0033] Residence time (min)

[0034] Under the same operating conditions, the water content of crude oil treated by the equipment of the present invention is less than 1%, meeting the technical requirements of commercial crude oil, while the crude oil treated by conventional separators needs to be further treated by electric dehyd...

Embodiment 2

[0036] In an offshore oilfield B in the north, due to the late stage of production, the water content of the produced well fluid is as high as 85%, and the density of crude oil at room temperature is 0.935g / cm 3 , using a conventional oil-gas-water three-phase separator, the operating pressure is 0.25MPa, the separation temperature is 64°C, and the liquid phase residence time is 10 minutes.

[0037] Adopt the equipment of the present invention to process the same well fluid, the operating pressure is 0.25MPa, the separation temperature is 64°C, the liquid phase residence time is 10 minutes, the treated crude oil has a water content of 3.5%, and the drain water has an oil content of 380mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com