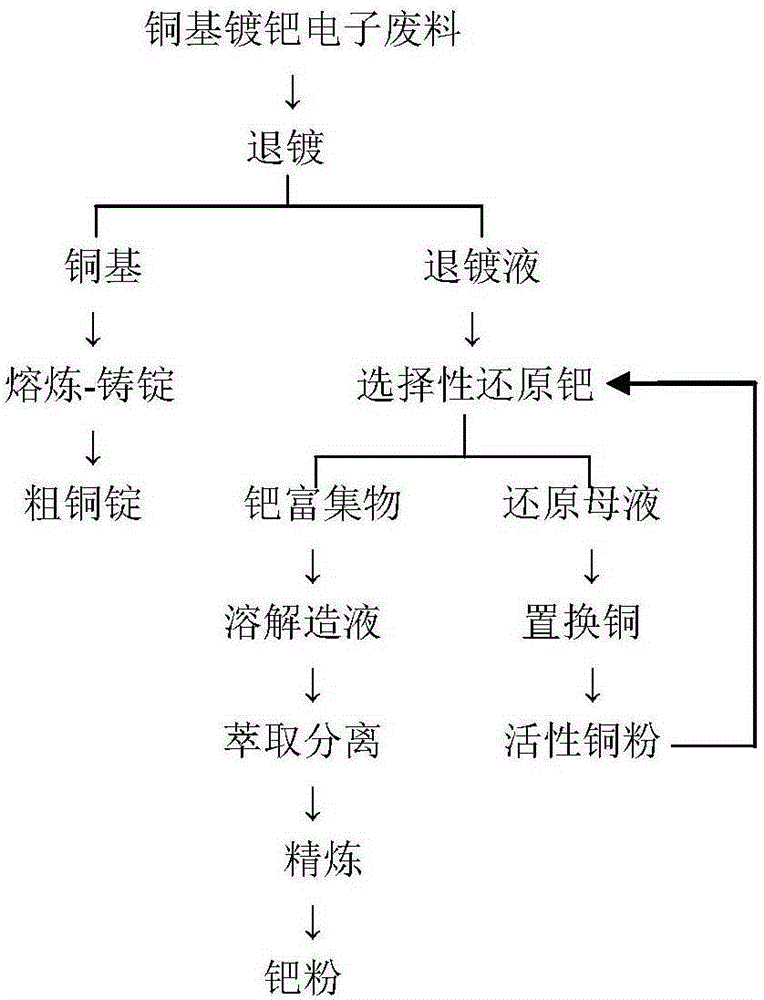

Palladium removing and copper extracting method for copper-based palladium plating electronic scraps

An electronic scrap and copper-based technology, which is applied in the direction of improving process efficiency, can solve the problems of corroding metal conductor circuits and containing cyanide, and achieves the effects of small copper-based damage, high selectivity, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Refer to the accompanying drawings, a kind of electronic waste, with copper as the matrix, containing 0.73% palladium and 98% copper, take 100g of it, add 1 ~ 2mol / LH according to the solid-liquid ratio (S / L) 1:2 2 SO 4 , 20~50%NaNO 3 , Sodium sulfanilate 1~2g / L, heated to 60°C for 1h, the plated piece changed from silvery white to yellow, the solution was blue, the palladium coating was completely removed, leaving a copper base weight of 93g, copper The recovery rate is 95%. The amount of palladium metal in the deplating solution is too small and has not been dealt with separately.

Embodiment 2

[0035] Example 2 Referring to the accompanying drawings, a kind of electronic scrap, with copper as the matrix, containing 0.87% palladium and 98% copper, takes 100g of it, and adds 3 to 6mol / L HCl, 10~50%H 2 o 2 1. Sodium aminobenzenesulfonate 1 ~ 2g / L, heated to 80 ℃ for 2 hours, the plated parts changed from silvery white to yellow, the solution was blue, and most of the palladium coating was removed, but a small part was not removed. , leaving a copper base weight of 94g, and a copper recovery rate of 96%. The amount of palladium metal in the deplating solution is too small and has not been dealt with separately.

Embodiment 3

[0037] Example 3 Referring to the accompanying drawings, a kind of electronic scrap, with copper as the matrix, containing 0.87% palladium and 98% copper, takes 100g of it, and adds 3-6mol / L HCl, 10~20%NaClO 3 , FeCl 3 1~2g / L, heated to 80℃ for 2 hours, the plated parts changed from silvery white to yellow, the solution was blue, a small amount of hydrolyzate was produced in the solution, most of the palladium coating was removed, but a small part remained Retire, leave copper basis weight 93g, copper recovery rate 95%. The amount of palladium metal in the deplating solution is too small and has not been dealt with separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com