Detection method for antibacterial agent in textile product

A detection method and technology for antibacterial agents, applied in the field of product safety and detection, can solve problems such as being unsuitable for the detection of various antibacterial agents, and achieve the effect of facilitating the end point of liquid-solid extraction, improving extraction efficiency and realizing control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

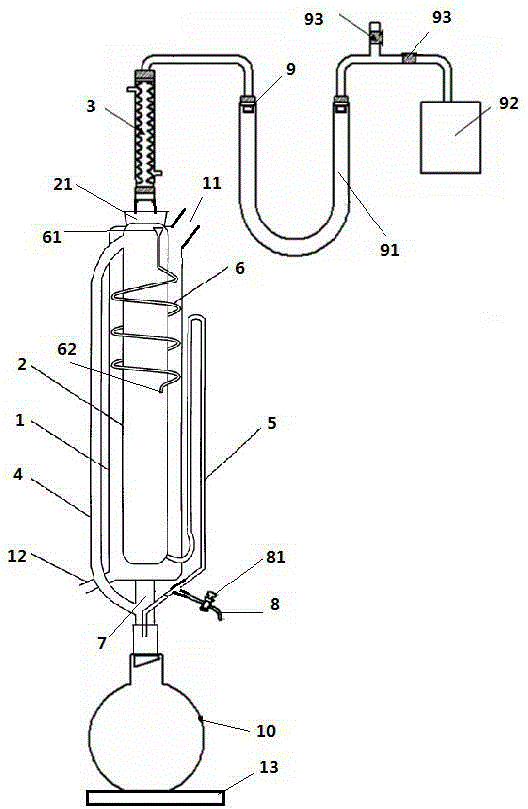

Method used

Image

Examples

Embodiment 1

[0053] 1. Test method

[0054] 1.1 Sample pretreatment

[0055] Take a representative sample, cut it into small pieces of about 5mm×5mm, then weigh 1.0g (accurate to 0.01g), add 80mL of ethanol, and perform Soxhlet extraction for 2 hours.

[0056] 1.2 Test equipment

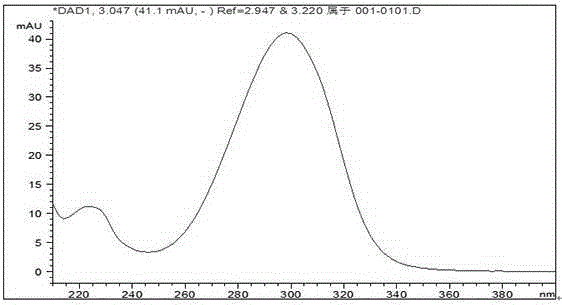

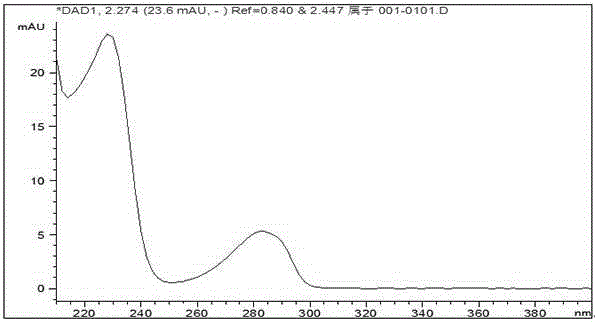

[0057] The detection method is to use EclipseXDB-C18 column, the specification is 250mm×4.6mm×5μm; the first mobile phase is acetonitrile and deionized water, the volume ratio is 50:50, the flow rate is 1mL / min; the column temperature is 30; the injection volume It is 10μL; the detector is a diode array detector.

[0058] The mobile phase also includes a second mobile phase; the second mobile phase is a phosphate buffer with a pH value of 3.5;

[0059] The specific detection method is to use a C18 column to split the components in the extract:

[0060] At 0-25min, the volume ratio of the first mobile phase to the second mobile phase was 88 / 12; at 26-35min, the volume ratio of the first mobile phase to the sec...

Embodiment 2

[0062] Take a representative sample, cut it into 0.5g small pieces, add 50mL ethanol, and extract by Soxhlet for 1.5h; then take the extract for testing;

[0063] The detection method is a C18 column, the first mobile phase includes acetonitrile and deionized water, and the column temperature is 25°C; the detector is a diode array detector.

[0064] The mobile phase also includes a second mobile phase; the second mobile phase is a phosphate buffer with a pH value of 4.5;

[0065] The second mobile phase phosphate buffer was prepared by mixing 0.25% phosphoric acid solution and 12% sodium hydroxide solution to a pH value of 4.5.

[0066] The preparation method of phosphate buffer solution is: titrate 0.2% phosphoric acid solution to 10% sodium hydroxide solution, add air by stirring while titrating, and mix until the pH value is 4.0.

[0067] The specific detection method is to use a C18 column to split the components in the extract:

[0068] At 0-25min, the volume ratio of t...

Embodiment 3

[0070] Take a representative sample, cut it into 1.5g small pieces, add 200mL ethanol, and extract by Soxhlet for 3h;

[0071] Then take the extract and detect it;

[0072] The detection method is a C18 column, the first mobile phase includes acetonitrile and deionized water, and the column temperature is 35°C; the detector is a diode array detector.

[0073] The mobile phase also includes a second mobile phase; the second mobile phase is a phosphate buffer with a pH value of 4.0;

[0074] The second mobile phase phosphate buffer was prepared by mixing 0.15% phosphoric acid solution and 8% sodium hydroxide solution to a pH value of 4.0.

[0075] More preferably, the preparation method of the phosphate buffer is: titrate 0.2% phosphoric acid solution to 10% sodium hydroxide solution, add air by stirring while titrating, and mix until the pH value is 4.0.

[0076] The specific detection method is to use a C18 column to split the components in the extract:

[0077] At 0-25min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com