Magnetic metal-organic framework material with core-shell structure and preparation method therefor

A technology of magnetic metals and organic frameworks, applied in the direction of microsphere preparation, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of material waste and difficult separation, improve utilization efficiency, prevent agglomeration, and achieve reliable performance controlling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

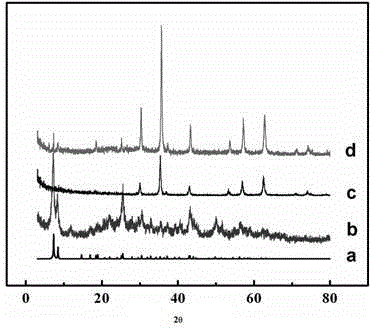

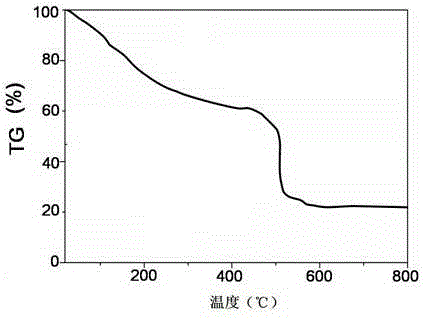

[0039] Embodiment 1, magnetic Fe 3 o 4 Preparation of UiO-66 material

[0040] (1) Magnetic Fe 3 o 4 Preparation of nanoparticles: 2.6g FeCl 3 ·6H 2 O was dissolved in 50mL of ethylene glycol solution and stirred vigorously to form a clear solution, then 5.75g of NaAc was added, and the mixture was magnetically stirred for 30min to obtain a dark brown viscous liquid, and then the liquid was transferred to a PTFE-lined stainless steel reaction In the kettle, the temperature was raised to 200°C in a constant temperature blast drying oven, and after 8 hours of reaction, it was naturally cooled to room temperature. The solution in the kettle was taken out, washed several times with absolute ethanol and deionized water, and vacuum-dried at 60°C to obtain a black powder. is Fe 3 o 4 Nanoparticles, the particle size is 600~700nm.

[0041] (2) Magnetic Fe 3 o 4 Particle surface thioglycolic acid modification: 200mg (0.864mmol) Fe 3 o 4 Dissolve in 40mL ethanol and ultrason...

Embodiment 2

[0045] (1) Magnetic Fe 3 o 4 Preparation of nanoparticles: same as Example 1;

[0046] (2) Magnetic Fe 3 o 4 Particle surface modification with thioglycolic acid: same as Example 1;

[0047] (3) Magnetic Fe 3 o 4 Preparation of UIO-66 material: Magnetic Fe modified with thioglycolic acid 3 o 4 Disperse the particles in 10mL of DMF, add triethylamine to adjust the pH=5, add 10mL of 34.3mM ZrCl dropwise under stirring 4 solution, stirred at 70°C for 30min, washed with DMF, dispersed in 20mL of 17.15mM terephthalic acid solution, and mechanically stirred at 70°C for 1h to obtain magnetic Fe 3 o 4 Magnetic microspheres with UiO-66 porous skeleton as the core. The above operation was repeated 3 times, and the obtained microspheres had a particle size of 630-760 nm and a shell thickness of 20-40 nm.

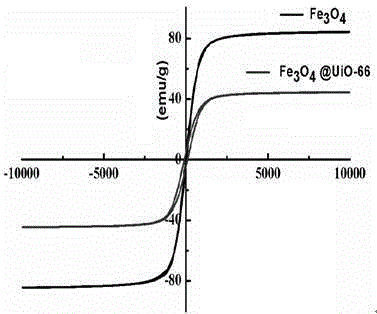

[0048] Fe prepared by cycling three times 3 o 4 UIO-66 has a saturation magnetization of 67 emug -1 . Fe wrapped with UIO-66 after three cycles 3 o 4 The magnetization...

Embodiment 3

[0050] (1) Magnetic Fe 3 o 4 Preparation of nanoparticles: same as Example 1;

[0051] (2) Magnetic Fe 3 o 4 Particle surface modification with thioglycolic acid: same as Example 1;

[0052] (3) Magnetic Fe 3 o 4 Preparation of UIO-66 material: Magnetic Fe modified with thioglycolic acid 3 o 4 Disperse the particles in 10mL of DMF, add triethylamine to adjust the pH=5, add 10mL of 34.3mM ZrCl dropwise under stirring 4 solution, stirred at 70°C for 30min, washed with DMF, dispersed in 20mL of 17.15mM terephthalic acid solution, and mechanically stirred at 70°C for 1h to obtain magnetic Fe 3 o 4 Magnetic microspheres with UiO-66 porous skeleton as the core. Continuously repeat the above operation 6 times, and the obtained microspheres have a particle size of 660-830 nm and a shell thickness of 40-80 nm.

[0053] Fe prepared by cycling 6 times 3 o 4 The saturation magnetization of UIO-66 is 52emug -1 . Fe after 6 cycles of wrapping UIO-66 3 o 4 The decreased magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com