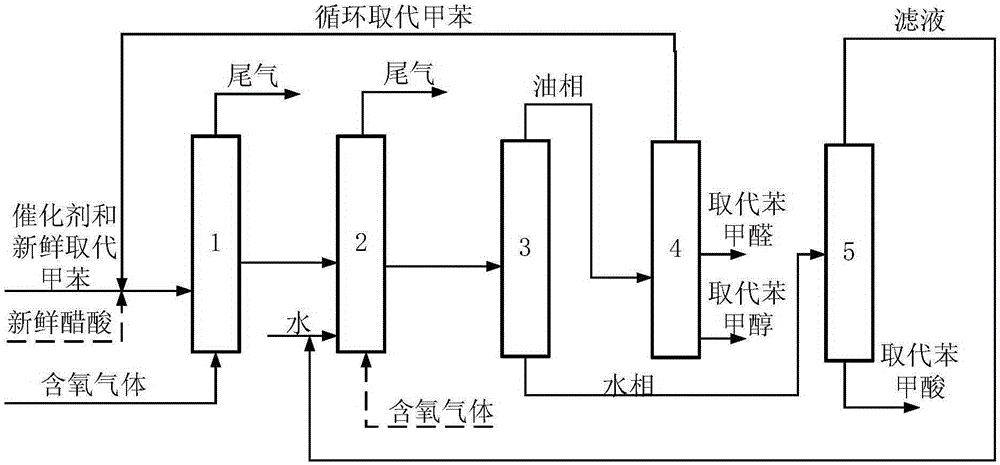

Combined production method for substituted benzaldehyde, substituted benzyl alcohol and substituted benzoic acid

A technology of benzyl alcohol and benzaldehyde, which is applied in the field of preparation of aromatic compounds, can solve the problems of unsuitable for large-scale production, low production efficiency and high production cost, and achieve the effects of improving utilization rate, saving energy consumption and reducing the probability of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

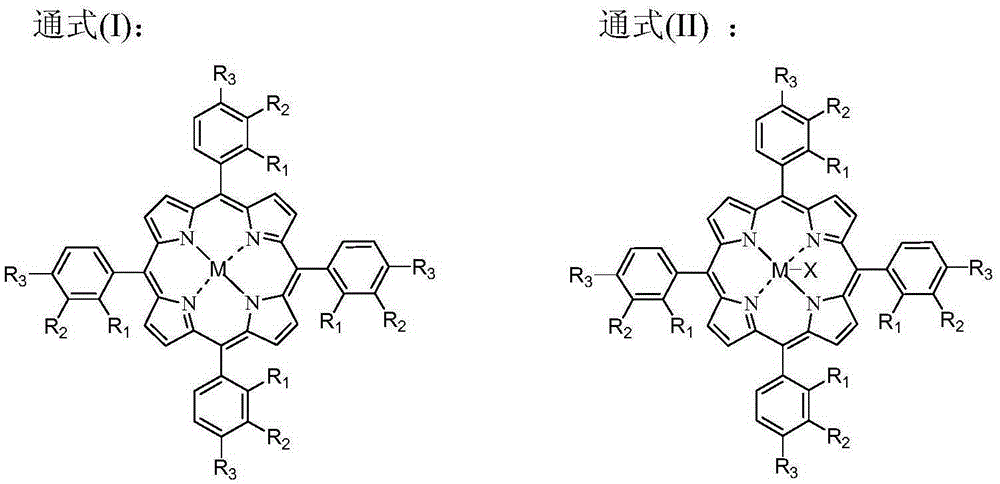

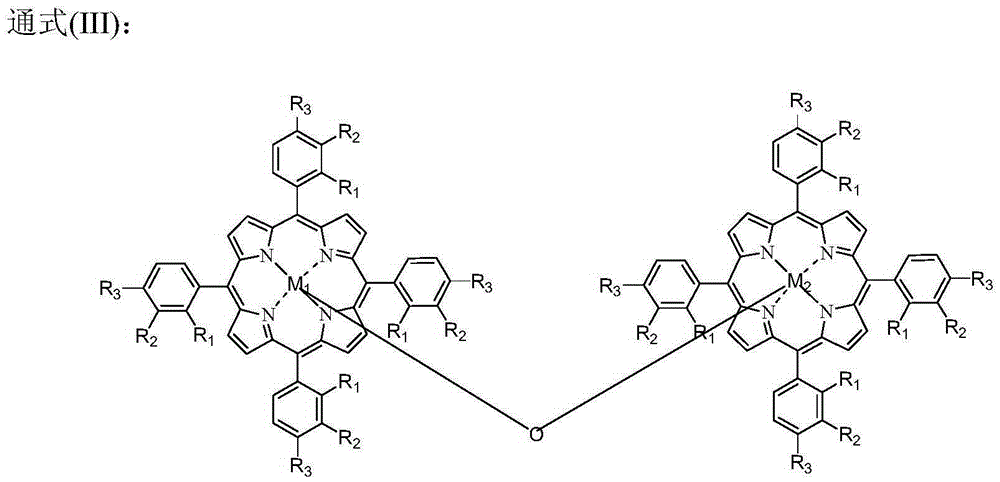

Embodiment 1

[0060] The catalyst dissolved in the fresh material p-chlorotoluene and acetic acid added to the system is HfO 2 , N-hydroxyl o-sulfonyl benzamide, metal phthalocyanine (R) with general formula (IV) structure 1 = H, R 2 =F, M=Fe) and metalloporphyrins (R 1 =R 3 =OH,R 2 =H, M=Ru), the total concentration is 600ppm, and the mass ratio of solvent to p-chlorotoluene is 0.026. When the device is in steady state operation, the flow rate of fresh material added to the oxidation reactor is 6.2mL / h. At this time, the average residence time of the oxidation reactor in terms of liquid phase substances is 2.4h, and the pressurized pure oxygen is continuously introduced into the oxidation reactor. In the reactor, the reaction temperature of the system is maintained at 165° C., and the reaction pressure is 1.4 MPa. The volume ratio of the amount of water added to the hydrolysis reactor to the oxidation reaction solution entering the hydrolysis reactor is 0.33:1, and oxygen-depleted air...

Embodiment 2

[0062] The catalyst that dissolves in the fresh o-fluorotoluene that adds in the primary oxidation reactor is the metal phthalocyanine (R with general formula (IV) structure 1 = H, R 2 =CH 3 CH 2, M=Co) and a mixture of manganese acetylacetonate, the total concentration is 450ppm. When the device is in steady state operation, the flow rate of fresh o-fluorotoluene added to the oxidation reactor is 10.9mL / h. At this time, the average residence time of the oxidation reactor in terms of liquid phase substances is 2.2h, and the pressurized pure oxygen is continuously passed through into the oxidation reactor to maintain the reaction temperature of the system at 185°C and the reaction pressure at 1.7MPa. The volume ratio of the amount of water added to the hydrolysis reactor to the oxidation reaction liquid entering the hydrolysis reactor is 0.90:1, and the reaction temperature in the hydrolysis reactor is maintained at 144°C, and the reaction pressure is 1.2MPa. At this time, t...

Embodiment 3

[0064] The catalyst dissolved in the fresh material p-bromotoluene and acetic acid added to the primary oxidation reactor is Mn(Ac) 2 4H 2 O, metal phthalocyanine (R) with general formula (IV) structure 1 = NO 2 , R 2 =H, M=Co), the metalloporphyrin (R 1 = R 3 = H, R 2 =CH 3 CH 2 , M=Cu) mixture, the total concentration is 120ppm, and the mass ratio of acetic acid to p-bromotoluene is 0.056. When the device is in steady state operation, the flow rate of fresh material added to the oxidation reactor is 14.5mL / h. At this time, the average residence time of the oxidation reactor in terms of liquid phase material is 1.5h, and the pressurized pure oxygen is continuously introduced into the oxidation reactor. In the reactor, the reaction temperature of the system is maintained at 190° C., and the reaction pressure is 1.8 MPa. The volume ratio of the amount of water added to the hydrolysis reactor to the oxidation reaction solution entering the hydrolysis reactor is 0.28:1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com