Water-stabilized zinc-copper metal organic frame material and preparation method and application thereof

An organic framework and copper metal technology, applied in the chemical field, can solve instability and other problems, and achieve the effects of high water stability, high CO2 adsorption capacity, and high BET specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Zn 0.99 Cu 0.01 Preparation of BIms.

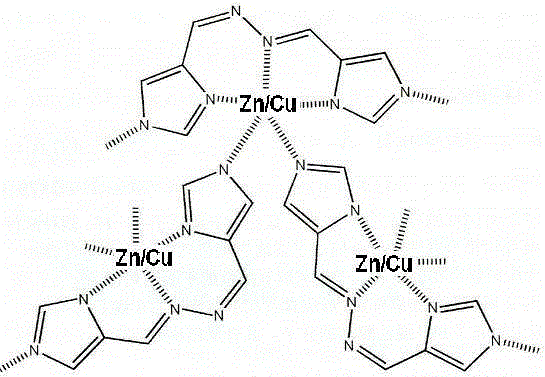

[0049] 883.49mg or 2.97mmol Zn (NO 3 ) 2· 6H 2 O, 7.248mg or 0.03mmol of Cu(NO 3 ) 2 Dissolve 564.6 mg, ie 3 mmol, of organic ligand BIm in 160 mL of DMF and 40 mL of ethanol, react at 100° C. for 72 h, and then cool to room temperature. Filter, wash with 60mL DMF, and dry to obtain the product, yield: 91.16%. structured as figure 1 Shown, has the general chemical formula Zn x Cu 1-x BIm (x0.99 Cu 0.01 The metal site of BIM has a helical icosahedral structure and contains three-dimensional channels with left-handed helix and right-handed helix as mirror images.

[0050] (2) Zn 0.95 Cu 0.05 Preparation of BIms.

[0051] 847.79mg or 2.85mmol of Zn(NO 3 ) 2· 6H 2 O, 36.24mg or 0.15mmol of Cu(NO 3 ) 2 Dissolve 564.6mg, ie 3mmol, of organic ligand BIm in 150mL DMF and 50mL ethanol, react at 100°C for 72h, and then cool to room temperature. Filter, wash with 60mL DMF, and dry to obtain the target product, yield: 9...

Embodiment 2

[0059] Zn prepared by different methods 0.99 Cu 0.01 BIm.

[0060] method 1:

[0061] 11.78mg or 0.0396mmol Zn (NO 3 ) 2· 6H 2 O, 0.09664mg that is 0.0004mmolCu (NO 3 ) 2 Dissolve 7.45 mg or 0.04 mmol of organic ligand BIm in 2 mL of DMF and 0.5 mL of ethanol, transfer the solution to a flask, seal it and put it in an oven, react at 140 °C for 24 h, then cool to room temperature at a rate of 5 °C / h . Filter and wash with DMF to obtain light green massive crystals, yield: 50.25%.

[0062] Method 2:

[0063] 11.78mg or 0.0396mmol Zn (NO 3 ) 2· 6H 2 O, 0.09664mg that is 0.0004mmolCu (NO 3 ) 2 Dissolve 7.45 mg of 0.04 mmol of organic ligand BIm in 2 mL of DMF and 0.5 mL of ethanol, transfer the solution to a hard glass tube with an inner diameter of 8 mm, seal it and put it in an oven, react at 100 ° C for 72 h, and then use 5 ° C / h to cool down to room temperature. Filter and wash with DMF to obtain light green massive crystals, yield: 51.68%.

[0064] Method 3...

Embodiment 3

[0074] Various properties of the zinc-copper mixed metal metal-organic framework material prepared in Example 1 and Example 2 were characterized.

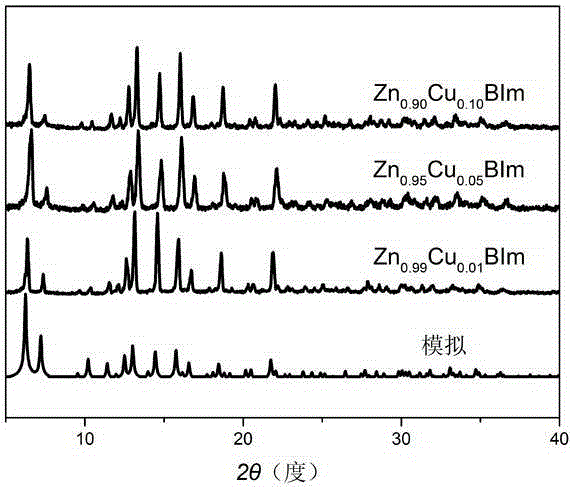

[0075] 1. Powder diffraction characterization of purity:

[0076] Zn 0.99 Cu 0.01 Bim, Zn 0.95 Cu 0.05 BIm and Zn 0.90 Cu 0.10 The powder diffraction data collection of BIm samples was completed on a BrukerD8advance diffractometer. The operating voltage of the instrument was 40KV, the current was 40mA, and the copper target X-ray (CuK, λ=1.5418?) monochromated by graphite was used in the range of 5° to 40° Continuous scanning is completed. The simulation transformation of powder diffraction spectrum of single crystal structure was performed using Mercury software. From figure 2 According to the powder diffraction data of the present invention, the three materials are isomorphic.

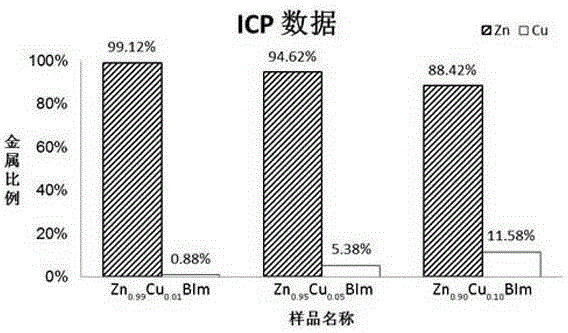

[0077] 2. Determination of metal ion content in zinc-copper metal organic framework.

[0078] (1) Inductively coupled plasma atomic emission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com