Construction of coenzyme efficient regeneration system and application thereof

A technology of dehydrogenase and formate dehydrogenase is applied in the field of Candida boidinia formate dehydrogenase gene sequence synthesis and preparation of α-aminobutyric acid, which can solve the problem of increasing the production cost and price of α-aminobutyric acid. Expensive, low formate dehydrogenase enzyme activity, etc., to achieve important industrial application value, improve conversion efficiency, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

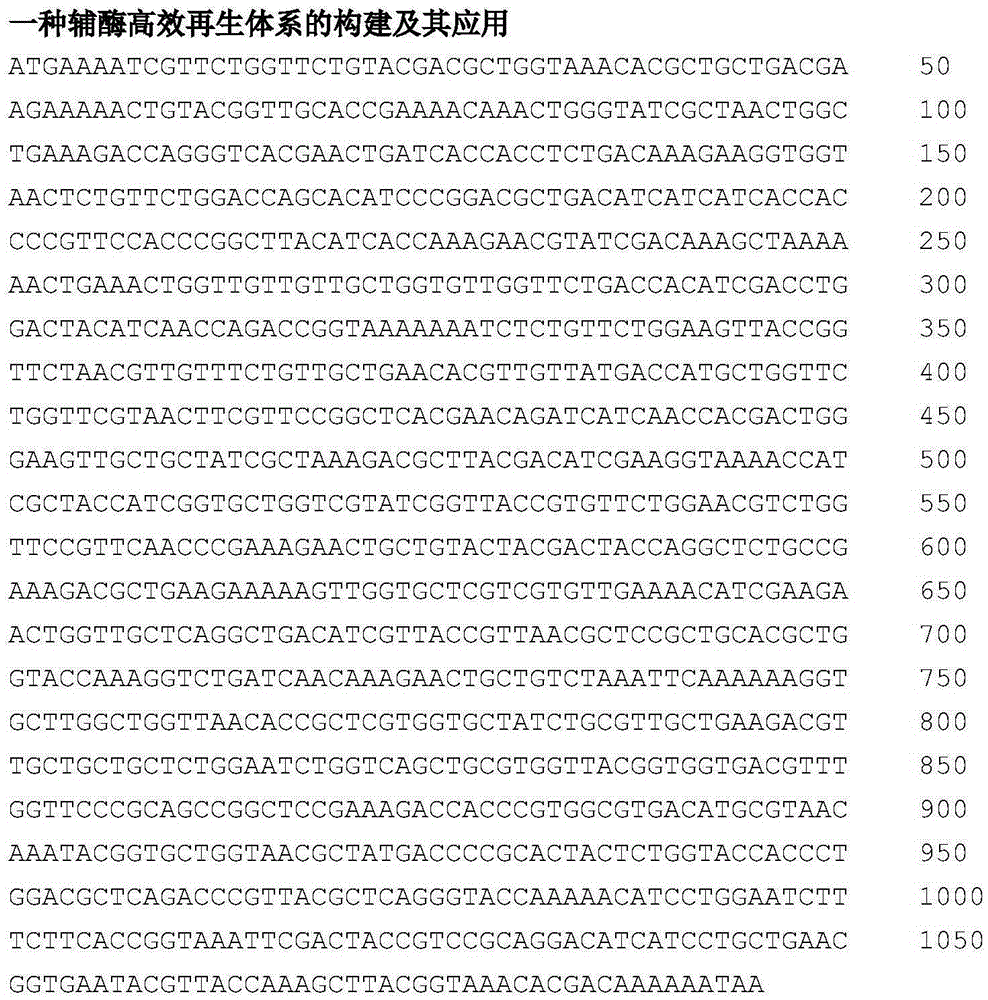

[0042] Example 1: Codon optimization of formate dehydrogenase

[0043] Upload the formate dehydrogenase gene sequence (fdh, GenBankAccessionNo.AJ011046) derived from Candida boidinii to http: / / www.jcat.de / to optimize the codon for the codon preference of Escherichia coli, and then send it to Shanghai Sangon Biotech Co., Ltd. performed gene synthesis. After the optimized gene fdh was compared with the original sequence by DNAMAN, it was found that the sequence homology was 80.37%.

Embodiment 2

[0044] Example 2: Construction and transformation of recombinant plasmid pET-28a-Bcldh / pET-28a-Rjpdh

[0045] [1] Genomic DNA of Bacillus cereus and Rhodococcus were used as templates.

[0046] [2] Design ldh gene primers according to the L-alanine dehydrogenase gene sequence of Bacillus subtilis and the L-phenylalanine dehydrogenase gene sequence of Rhodococcus and the restriction site on pET-28a plasmid.

[0047] PBcldhF: 5'-CGGGATCCATGACATTAGAAATCTTCG-3'(BamHI)

[0048] PBcldhR: 5'-CGAGCTCTTAGCGACGGCTAATAATATC-3'(SacI)

[0049] PRjpdhF: 5'-CGGGATCCATGACTCTCACCGCGGAAC-3' (BamHI)

[0050] PRjpdhR: 5'-CGAGCTCCTACCTGGCTGCAGCGATG-3'(SacI)

[0051] [3] The DNA of Bacillus cereus and Rhodococcus was used as a template to amplify the gene by PCR. PCR amplification system: template 2 μL, upstream and downstream primers 0.5 μL, dNTPMix 4 μL, 10×ExTaqBuffer 5 μL, sterilized ddH 2 O37 μL, ExTaq DNA polymerase 1 μL. PCR reaction conditions: 94°C pre-denaturation, 5min, one cycle; ...

Embodiment 3

[0054] Example 3: Construction and transformation of recombinant plasmid pET-28a-fdh+Bcldh / pET-28a-fdh+Rjpdh

[0055] [1] Synthetic codon-optimized formate dehydrogenase DNA was used as a template.

[0056] [2] Design fdh gene primers according to the synthesized codon-optimized formate dehydrogenase gene sequence and restriction sites on pET-28a and pET-duet plasmids. According to the codon-optimized fdh gene sequence, primers P1 and P2 of formate dehydrogenase gene and primers P3 and P4 co-expressed with L-amino acid dehydrogenase in pET-28a were designed.

[0057] P1: 5'-ACCGGGATCCATGAAAATCGTTCTGGTTCTG-3'(BamHI)

[0058] P2: 5'-CGCGTCGACTTATTTTTTGTCGTGTTTACC-3'(SalI)

[0059] P3: 5'-ACATGCATGCCGATCCCGCGAAATTAATAC-3'(SphI)

[0060] P4: 5'-GAAGATCTTTATTTTTTTGTCGTGTTTACC-3' (BglII)

[0061] [3] Use the synthesized formate dehydrogenase DNA as a template, and use P1 and P2 as primers to amplify the gene by PCR. PCR amplification system: template 2 μL, upstream and downstre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com