Construction method and detection method of potassium ion nucleic acid aptamer photoelectrochemical sensor based on diluted magnetic semiconductor

A nucleic acid aptamer and dilute magnetic semiconductor technology, applied in the field of chemical analysis and testing, to achieve the effects of improving sensitivity, simple equipment and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

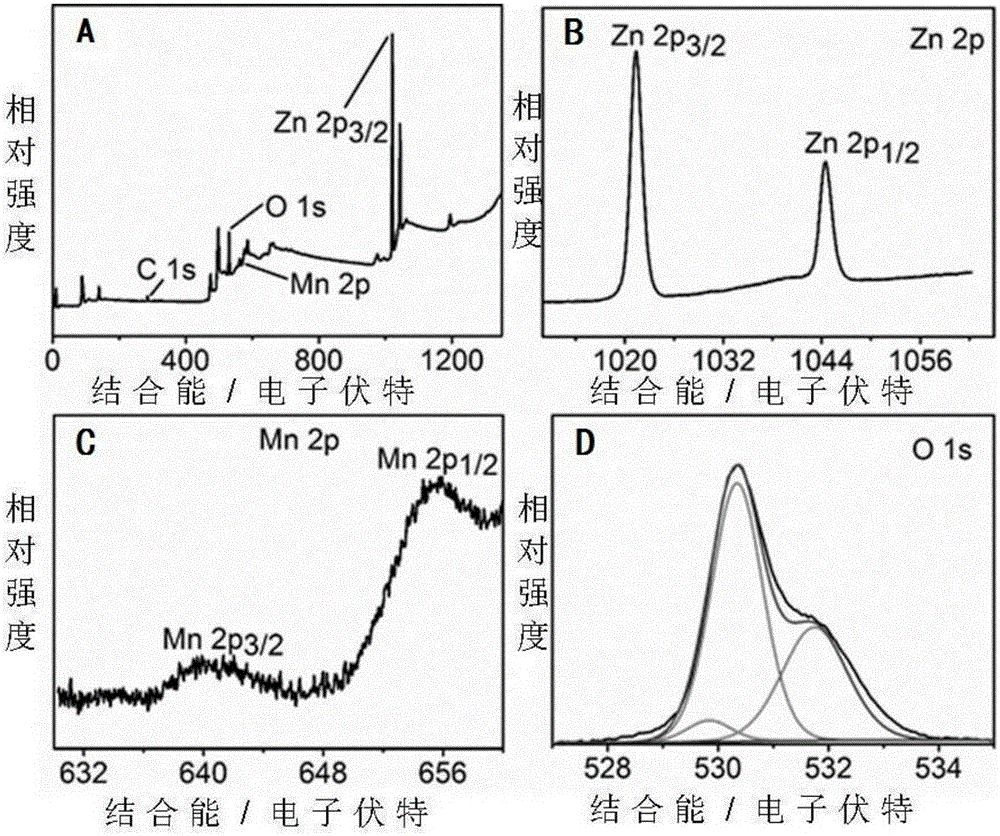

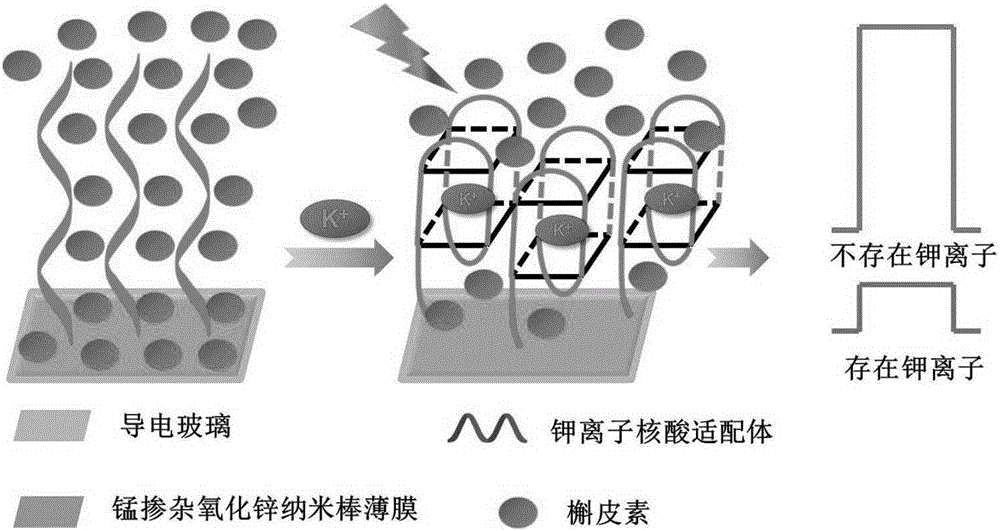

[0034] Embodiment 1: A method for constructing a potassium ion nucleic acid aptamer photoelectrochemical sensor based on a dilute magnetic semiconductor, comprising the following steps:

[0035] (1) Use a mixed solution of ammonia, hydrogen peroxide and water with a volume ratio of 1:1:50 to clean the ITO conductive glass electrode, then rinse it with water and dry it in the air for use;

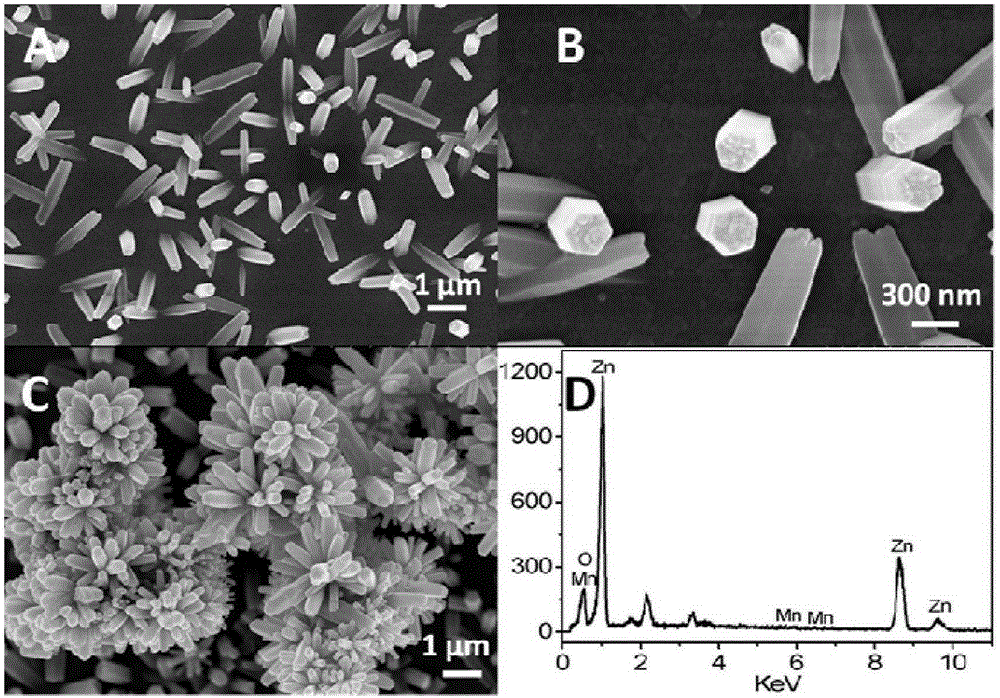

[0036] (2) The ITO conductive glass electrode after drying in the step (1) is immersed in the mixed solution of zinc nitrate, potassium nitrate and manganese sulfate to carry out electrochemical deposition, relative to the deposition potential of silver / silver chloride electrode is-1.0V , the deposition temperature is 80°C, and the deposition time is 120min. After deposition, the Mn-doped dendritic zinc oxide nanorod photoanode is obtained, and the concentration of zinc nitrate solution in the mixed solution is 0.5mmolL -1 , the concentration of potassium nitrate solution is 0.1molL -1 , th...

Embodiment 2

[0054] Embodiment 2: A construction method of a potassium ion nucleic acid aptamer photoelectrochemical sensor based on a dilute magnetic semiconductor, comprising the following steps:

[0055] (1) Use a mixed solution of ammonia, hydrogen peroxide and water with a volume ratio of 1:1:40 to clean the ITO conductive glass electrode, then rinse it with water and dry it in the air for use;

[0056] (2) The ITO conductive glass electrode after drying in step (1) is immersed in the mixed solution of zinc nitrate, potassium nitrate and manganese sulfate to carry out electrochemical deposition, is-0.8V relative to the deposition potential of silver / silver chloride electrode , the deposition temperature is 60°C, and the deposition time is 150min. After deposition, the Mn-doped dendritic zinc oxide nanorod photoanode is obtained, and the concentration of the zinc nitrate solution in the mixed solution is 0.8mmolL -1 , the concentration of potassium nitrate solution is 0.15molL -1 , th...

Embodiment 3

[0065] Embodiment 3: A construction method of a potassium ion nucleic acid aptamer photoelectrochemical sensor based on a dilute magnetic semiconductor, comprising the following steps:

[0066] (1) Use a mixed solution of ammonia, hydrogen peroxide and water with a volume ratio of 1:1:30 to clean the ITO conductive glass electrode, then rinse it with water and dry it in the air for use;

[0067] (2) The ITO conductive glass electrode after drying in the step (1) is immersed in the mixed solution of zinc nitrate, potassium nitrate and manganese sulfate to carry out electrochemical deposition, relative to the deposition potential of silver / silver chloride electrode is-1.2V , the deposition temperature is 100°C, and the deposition time is 90min. After the deposition, the Mn-doped dendritic zinc oxide nanorod photoanode is obtained, and the concentration of the zinc nitrate solution in the mixed solution is 0.3mmolL -1 , the concentration of potassium nitrate solution is 0.05molL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com