ZnO piezoelectric effect-based low-power consumption flexible resistance-variable memory and preparation method thereof

A technology of resistive memory and piezoelectric effect, applied in the field of non-volatile flexible resistive random access memory, can solve the problems of reduced device life, large operating voltage, and increased device power consumption, so as to reduce power consumption and reduce power consumption. Operating voltage, life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. RF magnetron sputtering of ZnO thin films

[0027] The ITO / PET substrates were super-cleaned in acetone, ethanol and deionized water respectively, and then dried with nitrogen. During the sputtering process, the system pressure was kept at 0.2 Pa, the Ar flow rate was 20 sccm, the sputtering power was 55 W, the deposition time was 30 minutes, and the film thickness range was 50 nm.

[0028] 2. Electron Beam Evaporation of Metal Copper Top Electrode

[0029] On the prepared ZnO thin film, place a piece of stainless steel mask plate punched with round holes to cover the lower electrode and part of the ZnO thin film, and then send the sample and the mask plate into an electron beam evaporation coating apparatus. When the background vacuum of the chamber is pumped to 6×10 -5 At Pa, open the evaporation barrier to deposit a metal Pt upper electrode with a thickness of 100 nm on the ZnO film.

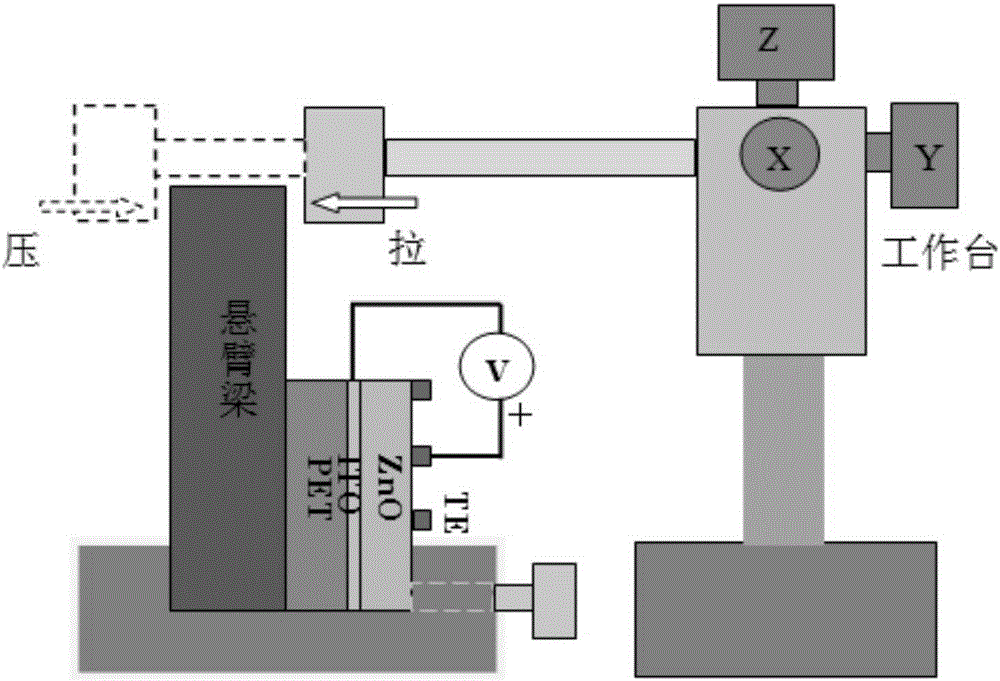

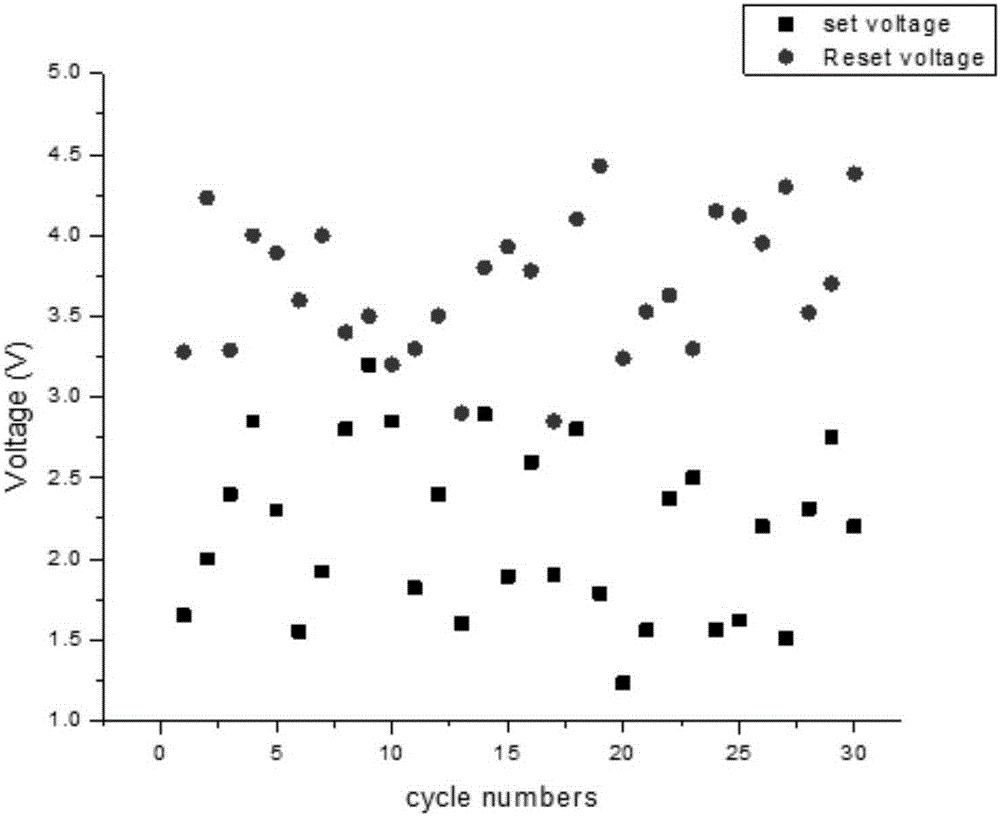

[0030] 3. Electrical performance test

[0031] By controlling the force act...

Embodiment 2

[0033] 1. RF magnetron sputtering of ZnO thin film

[0034] The ITO / PET substrates were super-cleaned in acetone, ethanol and deionized water respectively, and then dried with nitrogen. During the sputtering process, the system pressure was kept at 0.1 Pa, the Ar flow rate was 30 sccm, the sputtering power was 55 W, the deposition time was 60 minutes, and the film thickness range was 100 nm.

[0035] 2. Electron Beam Evaporation of the Metal Top Electrode

[0036] On the prepared ZnO thin film, place a stainless steel mask plate punched with round holes to cover the lower electrode and part of the ZnO thin film, and then send the sample and the mask plate into an electron beam evaporation coating apparatus. When the background vacuum of the chamber is pumped to 6×10 -5 When Pa, open the evaporation barrier to deposit a metal copper upper electrode with a thickness of 100 nm on the ZnO film.

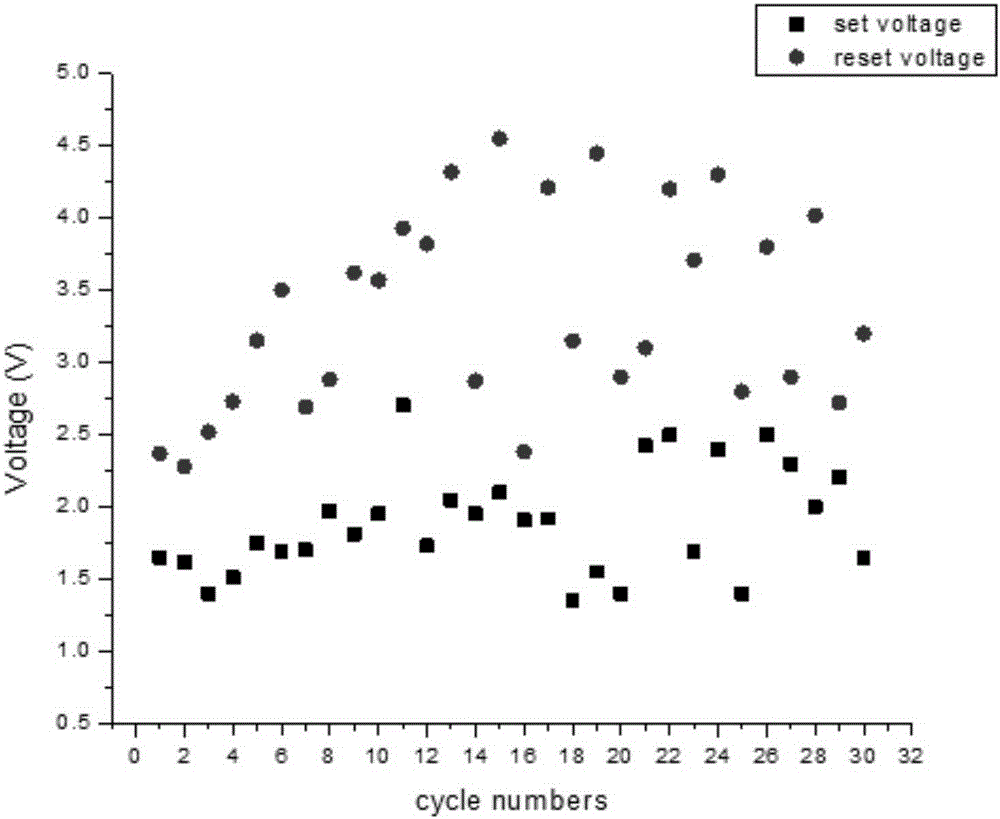

[0037] 3. Electrical performance test

[0038] By controlling the force acting on...

Embodiment 3

[0043] 1. RF magnetron sputtering of ZnO thin film

[0044] The ITO / PET substrates were super-cleaned in acetone, ethanol and deionized water respectively, and then dried with nitrogen. During the sputtering process, the system pressure was maintained at 0.3 Pa, the Ar flow rate was 20 sccm, the sputtering power was 55 W, the deposition time was 90 minutes, and the film thickness range was 150 nm.

[0045] 2. Electron Beam Evaporation of the Metal Top Electrode

[0046] On the prepared ZnO thin film, place a stainless steel mask plate punched with round holes to cover the lower electrode and part of the ZnO thin film, and then send the sample and the mask plate into an electron beam evaporation coating apparatus. When the background vacuum of the chamber is pumped to 6×10 -5 Pa, open the evaporation barrier to deposit a metal Au electrode with a thickness of 100 nm on the ZnO film.

[0047] 3. Electrical performance test

[0048] By controlling the force acting on the cant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com