Desulphurization wastewater zero discharge treatment process for power plant with low running cost

A technology for desulfurization wastewater and operating cost, which is applied in gaseous effluent wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve secondary pollution, high pretreatment operating cost, mixed Salt has no use value and other problems, to achieve the effect of reducing the dosage and realizing the recycling of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

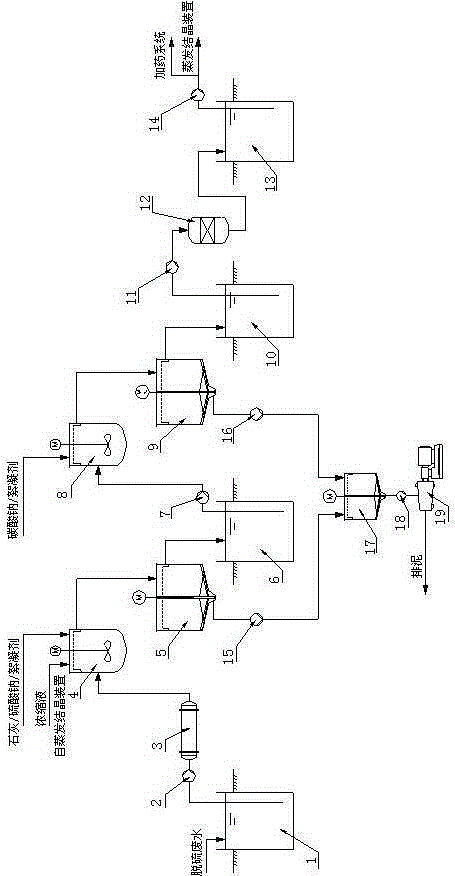

[0045] The present invention will be further described in detail below in conjunction with the drawings.

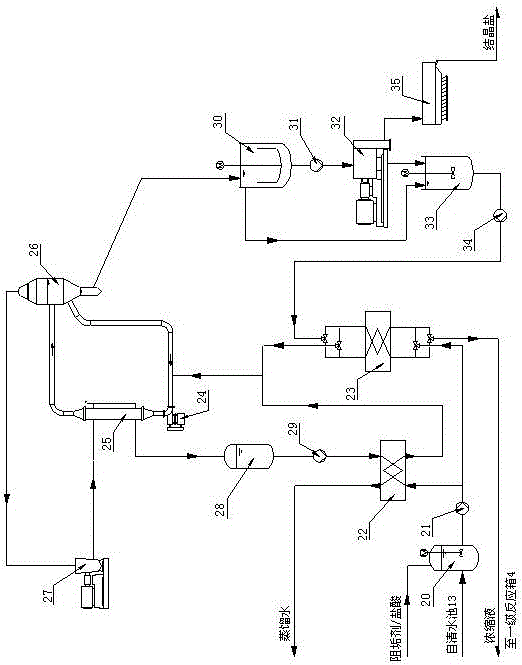

[0046] A low operating cost zero discharge treatment process for desulfurization wastewater in power plants, including pretreatment softening process and evaporation crystallization process,

[0047] Such as figure 1 As shown, the pretreatment softening process includes the following steps:

[0048] 1) The desulfurization wastewater enters the original pool 1 first, and the original pool 1 needs sufficient volume to reduce the fluctuation of the desulfurization wastewater;

[0049] 2) The wastewater transfer pump 2 is sent to the electronic flocculator 3. Due to the hydrolysis of the electronic flocculation, the pH of the wastewater increases, and part of the Mg 2+ Generate Mg(OH) 2 precipitation;

[0050] 3) Enter the first stage reaction box 4, and add Ca(OH) 2 , Na 2 SO 4 Reaction, heavy metal ions and Mg in wastewater 2+ Basically completely precipitated, with SO 4 2+ The conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com