Cement grinding aid and its preparation method and application method

A cement grinding aid and molasses technology, applied in the field of cement additives, can solve problems affecting the service life of buildings, water and soil pollution, steel corrosion, etc., achieve reasonable particle gradation and distribution, enhance comprehensive performance, and ensure grinding aid effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

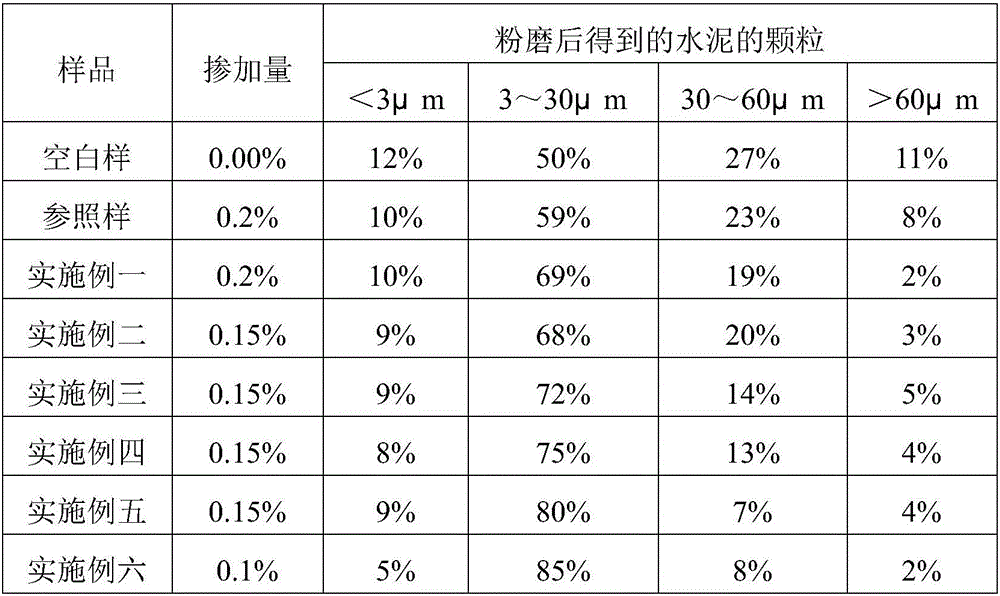

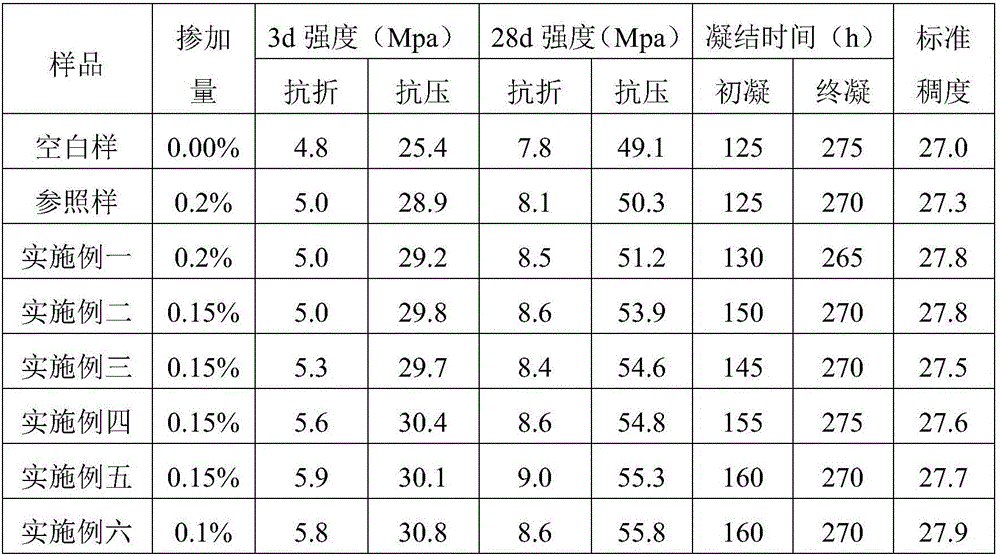

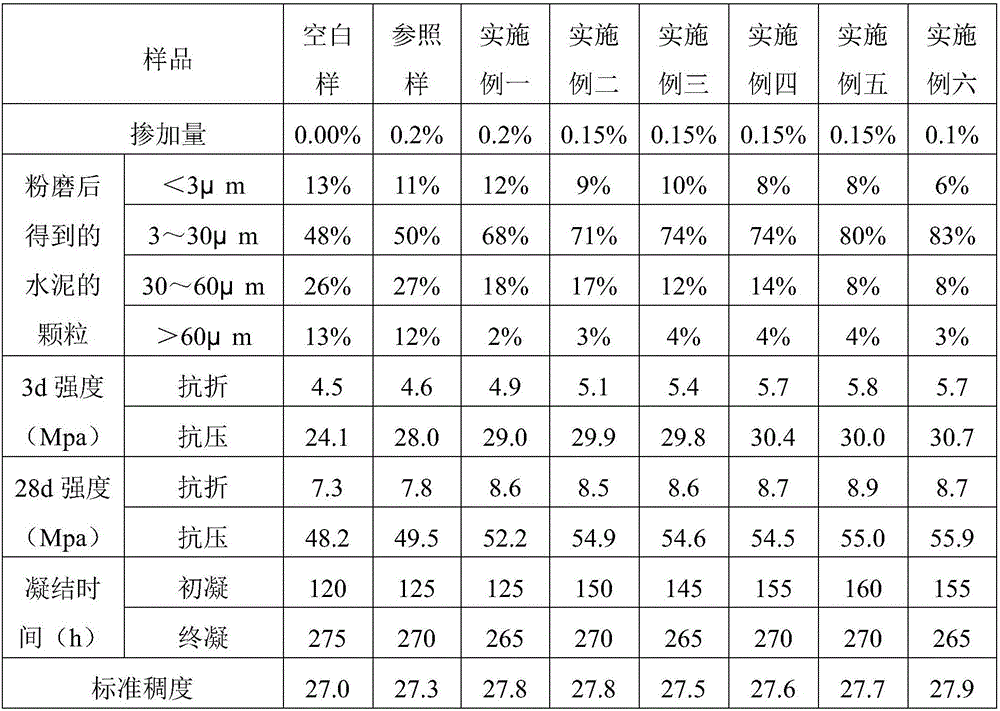

Examples

Embodiment 1

[0036] Get 1 part of sodium gluconate, 1 part of glucosamine sulfate potassium salt, 5 parts of n-propanol and 40 parts of water, stir and mix evenly to obtain the S1 mixture; get 5 parts of triethanolamine and 5 parts of molasses (in terms of converted sugar, its The total sugar content is 40%wt) and 60 parts of water, stir and mix uniformly to obtain the S2 mixture; add the S1 mixture to the S2 mixture, stir and mix uniformly to obtain the cement grinding aid of the present invention. Before the cement grinding aid is added to the cement grinding process of the cement product, the mass ratio of the cement grinding aid to the cement product is 0.1% to 0.2%.

Embodiment 2

[0038]Get 2 parts of sodium gluconate, 4 parts of glucosamine sulfate potassium salt, 8 parts of ethanol and 40 parts of water, stir and mix evenly to obtain the S1 mixture; get 8 parts of triethanolamine, 10 parts of molasses (in terms of converted sugar, the total The amount of sugar is 50%wt) and 45 parts of water, stir and mix uniformly to obtain the S2 mixture; add the S1 mixture to the S2 mixture, stir and mix uniformly to obtain the cement grinding aid of the present invention. Before the cement grinding aid is added to the cement grinding process of the cement product, the mass ratio of the cement grinding aid to the cement product is 0.1% to 0.2%.

Embodiment 3

[0040] Take 2 parts of sodium gluconate, 5 parts of glucosamine sulfate potassium salt, 10 parts of methanol and 30 parts of water, stir and mix evenly to obtain the S1 mixture; additionally get 10 parts of triethanolamine and 13 parts of molasses (in terms of converted sugar, the total The amount of sugar is 30%wt) and 40 parts of water, stir and mix uniformly to obtain the S2 mixture; add the S1 mixture to the S2 mixture, stir and mix uniformly to obtain the cement grinding aid of the present invention. Before the cement grinding aid is added to the cement grinding process of the cement product, the mass ratio of the cement grinding aid to the cement product is 0.1% to 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com