White beech mushroom culturing material and preparation method thereof

A technology of culture material and white jade mushroom, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of high incidence of diseases and insect pests, low nutritional content, poor product quality, etc., and achieve good growth, delicious taste, and good product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

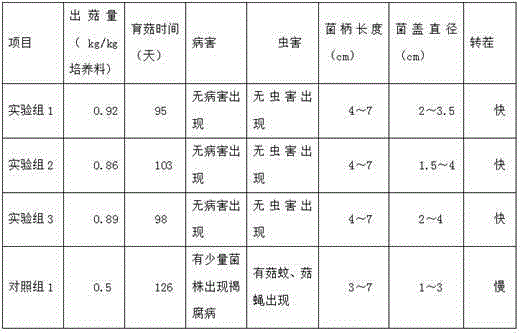

Examples

Embodiment 1

[0020] A white jade mushroom compost, comprising the following raw materials in parts by weight: straw 100, water chestnut vine 20, bran 3, water chestnut powder 3, superphosphate 1.5, potassium dihydrogen phosphate 5, green algae powder 3, shrimp and crab shell powder 4 , propolis 3, chitosan 0.5 and sucrose 0.5, wherein the straw is corn straw.

[0021] Straw and water chestnut vine pretreatment: crush the straw and water chestnut vine with a grinder, the length is 8-10cm, mix well to get a mixture, spray layer by layer zinc chloride aqueous solution accounting for 1% of the weight of the mixture, and press it layer by layer , sealed, anaerobic fermentation at 37°C for 30 days, when the pH dropped to 4.5, the surface was sprayed with 5% yeast fermentation liquid by weight of the mixture, sealed, anaerobic fermentation at 35-37°C for 15 days, steam at 100°C under normal pressure Bacteria, just dry. The mass concentration of the zinc chloride aqueous solution is 5%; the mass ...

Embodiment 2

[0027] A white jade mushroom compost, comprising the following raw materials in parts by weight: straw 100, water chestnut vine 15, bran 2, water chestnut powder 2, superphosphate 1, potassium dihydrogen phosphate 4, green algae powder 2, shrimp and crab shell powder 3 , propolis 3, chitosan 0.5 and sucrose 0.5, wherein the straw is cotton straw.

[0028] Straw and water chestnut pretreatment and preparation method, with embodiment 1.

Embodiment 3

[0030] A white jade mushroom compost, comprising the following raw materials in parts by weight: straw 100, water chestnut vine 25, bran 4, water chestnut powder 5, superphosphate 2, potassium dihydrogen phosphate 6, green algae powder 4, shrimp and crab shell powder 5 parts, propolis 4, chitosan 0.5 and sucrose 0.5, wherein the straw is corn stalk.

[0031] Straw and water chestnut pretreatment and preparation method, with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com