Composite anode material for lithium ion battery, and preparation method and application of composite anode material

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., and can solve the problems of high average voltage, low compaction density, and low energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

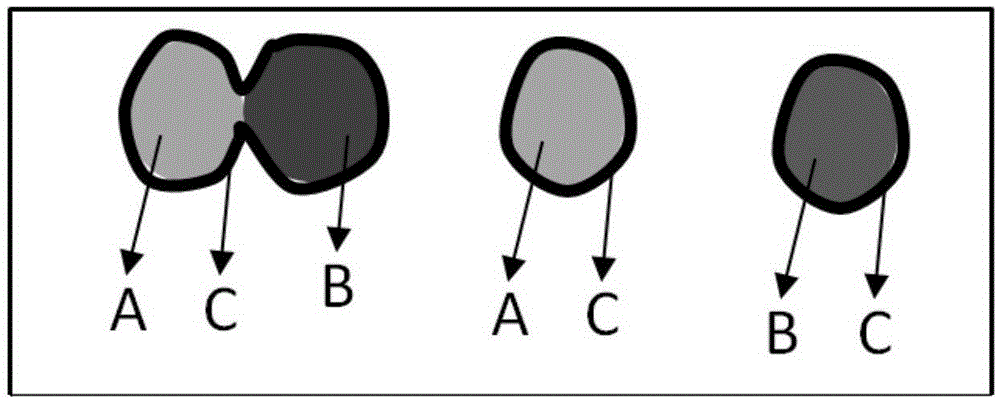

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

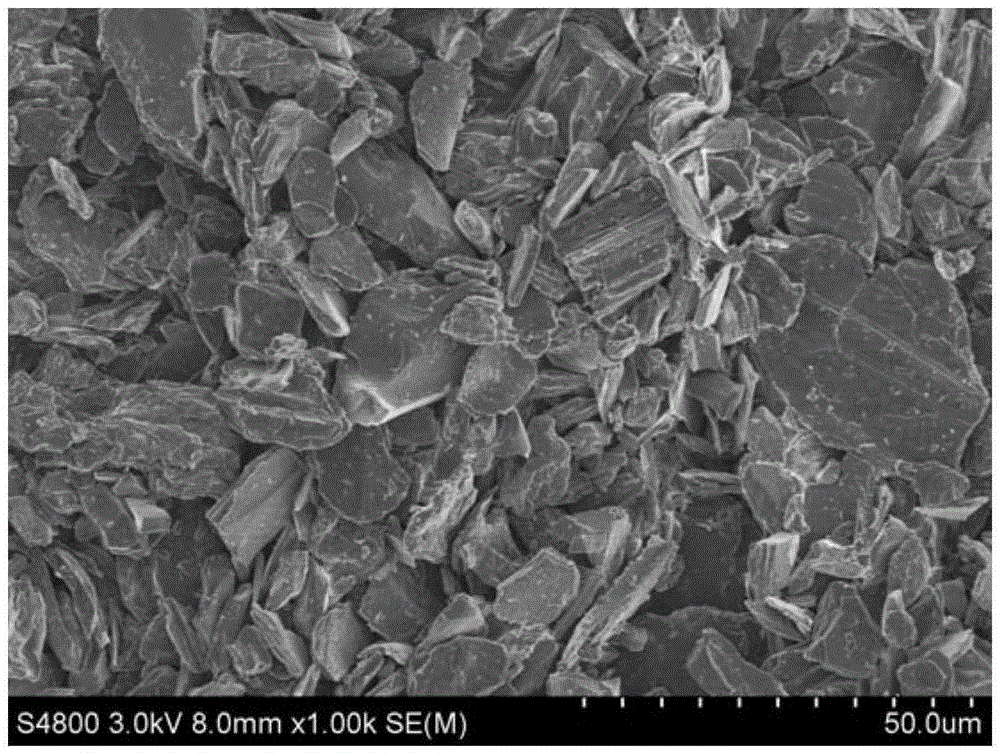

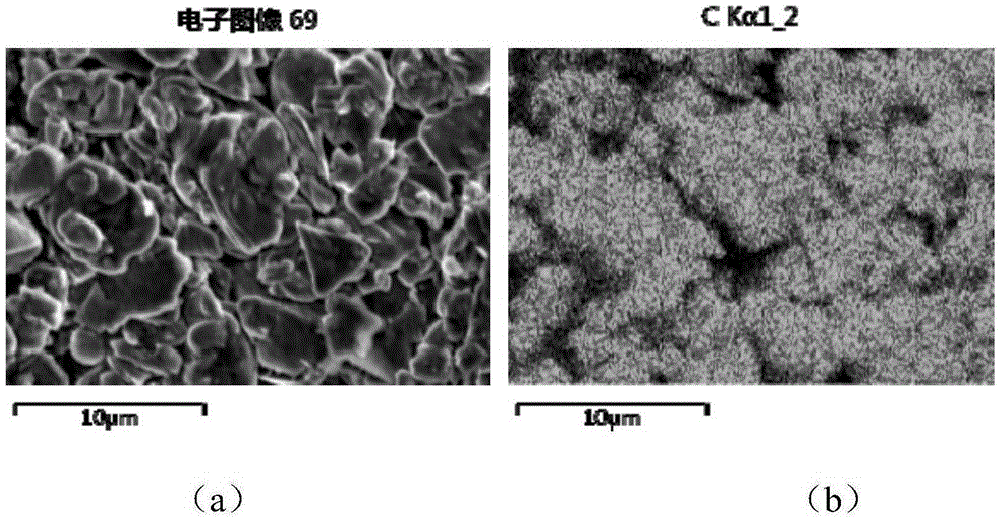

Embodiment 1

[0088] Petroleum-based green coke raw materials are obtained by jet milling and cyclone classification to obtain particle size D 50 = 8.0-10.0 micron green coke powder, mix the green coke powder and ammonium dihydrogen phosphate at a mass ratio of 97:3 with a VC mixer at a speed of 100r / min, and mix for 30min to obtain a mixture; put the above mixture in In the atmosphere furnace, the nitrogen flow rate is 120L / h, the temperature is raised to 950°C at a heating rate of 5°C / min, and the temperature is kept for 3h to obtain a phosphorus-doped coke-like soft carbon sample; the phosphorus-doped coke-like soft carbon is mixed with D 50 The artificial graphite of =12 microns is 50:50 according to mass ratio, mixes with VC mixer, rotating speed 100r / min, mixes 30min, the mixture obtained and phenolic resin are dispersed in ethanol solvent according to mass ratio 90:10, stir evenly, After heating and drying in a water bath, the mixture was placed in an atmosphere furnace with a nitrog...

Embodiment 2

[0096] Petroleum-based green coke raw materials are obtained by jet milling and cyclone classification to obtain particle size D 50 = 9.0-15.0 micron green coke powder, mix the green coke powder and ammonium dihydrogen phosphate at a mass ratio of 95:5 with a VC mixer at a speed of 100r / min, and mix for 30min to obtain a mixture; put the above mixture in In the atmosphere furnace, the nitrogen flow rate is 120L / h, the temperature is raised to 950°C at a heating rate of 5°C / min, and the temperature is kept for 3h to obtain a phosphorus-doped coke-like soft carbon sample; the phosphorus-doped coke-like soft carbon is mixed with D 50 The natural graphite of =12 microns is 50:50 according to mass ratio, mixes with VC mixer, rotating speed 100r / min, mixes 30min, the mixture obtained and epoxy resin are dispersed in Virahol solvent according to mass ratio of 80:20, Stir evenly, heat and dry the mixture in an oil bath, place the mixture in an atmosphere furnace with a nitrogen flow r...

Embodiment 3

[0098] Petroleum-based green coke raw materials are obtained by jet milling and cyclone classification to obtain particle size D 50 = 9.0-15.0 micron green coke powder, mix the green coke powder and ammonium dihydrogen phosphate at a mass ratio of 90:10 with a VC mixer at a speed of 100r / min, and mix for 30min to obtain a mixture; put the above mixture in In the atmosphere furnace, the nitrogen flow rate is 120L / h, the temperature is raised to 800°C at a heating rate of 5°C / min, and the temperature is kept for 3h to obtain a phosphorus-doped coke-like soft carbon sample; the phosphorus-doped coke-like soft carbon is mixed with D 50 The artificial graphite of =12 microns is 50:50 according to mass ratio, mixes with VC mixer, rotating speed 100r / min, mixes 30min, the mixture obtained and citric acid are dispersed in ethanol solvent according to mass ratio of 60:40, stir evenly, After spray drying, the mixture was placed in an atmosphere furnace with a nitrogen flow rate of 120L / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com